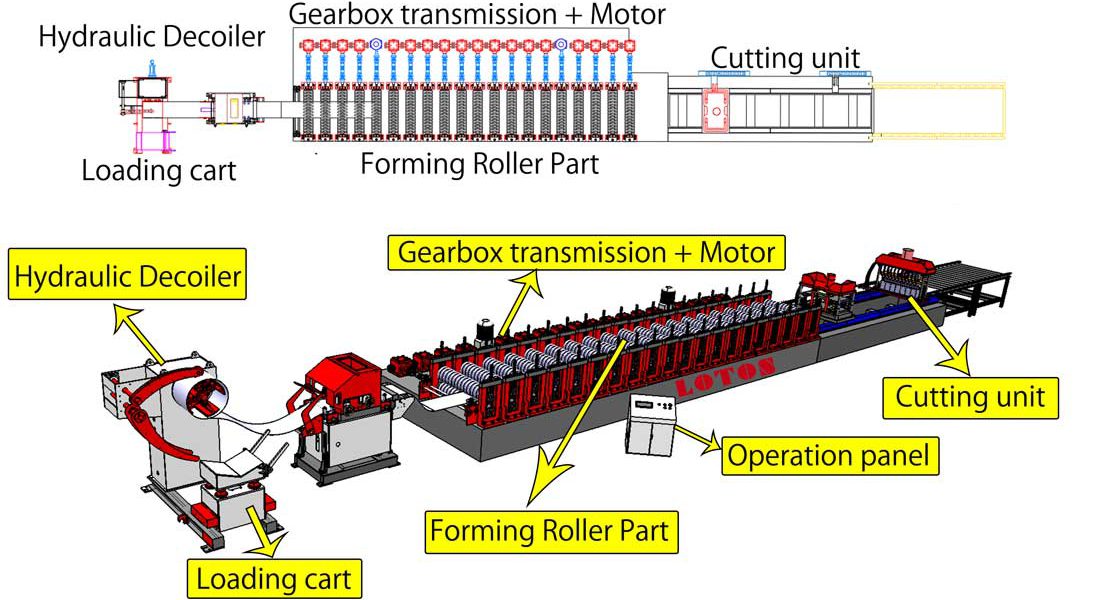

ROLL FORMING MACHINE MANUFACTURER

However, LOTOSFORMING is a professional ▷▷ ROll FOrming MAchine – Best Manufacturer 2024 in china. hence,

in fact, LOTOSFORMING seems to offer an extensive range of roll forming machines, catering to various industries and needs. From purlins to sheet panels, and even portable roll forming machines, they appear to cover a wide spectrum of manufacturing requirements.

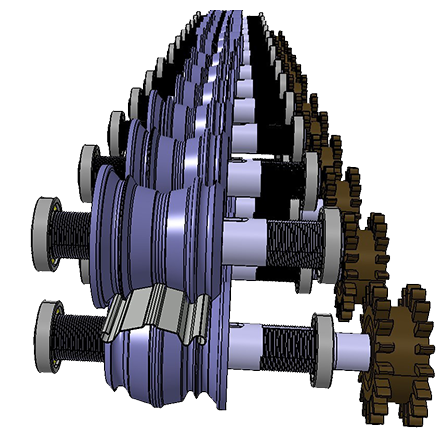

It’s interesting to note their focus on innovation and customization, evident in their ability to design and produce small roll forming machines for users with limited space, as well as portable metal roof roll forming machines for on-site panel production.

Therefore, Their commitment to being at the forefront of the roll forming industry in China suggests a dedication to quality and reliability in their products. It’s certainly intriguing to see how they continue to evolve and shape the future of roll forming technology.

LOTOSFORMING is a prominent roll forming machine manufacturer based in China. They specialize in designing and producing various types of roll forming machines for a wide range of industries and applications. LOTOSFORMING is known for its commitment to innovation, quality, and customization to meet the specific needs of their clients. With their expertise and dedication to customer satisfaction, LOTOSFORMING has established itself as a leading player in the roll forming industry.