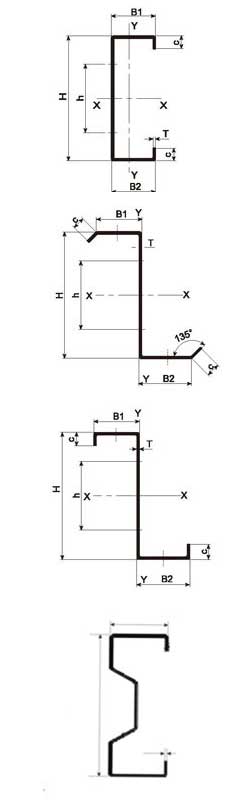

Purlin Machine

Production Working Flow

Manual decoiler →7-roller leveling→ feeding→ puncher unit→ pre-cutting die→ roll forming machine→output table

The Main Purpose and Characteristics

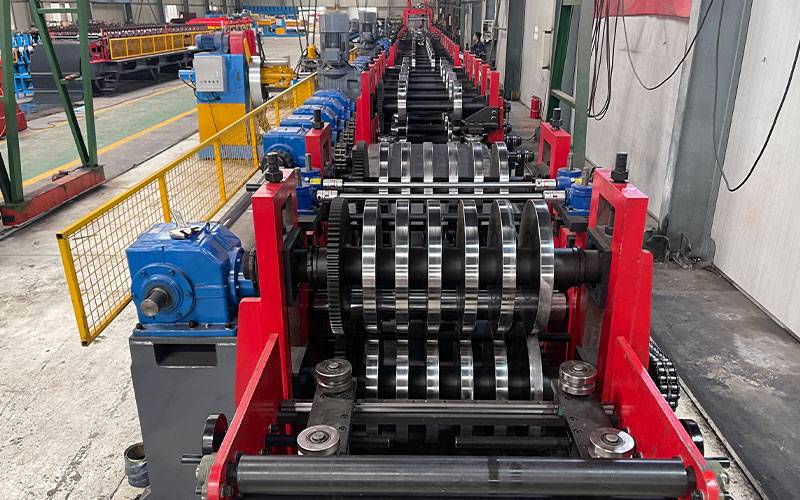

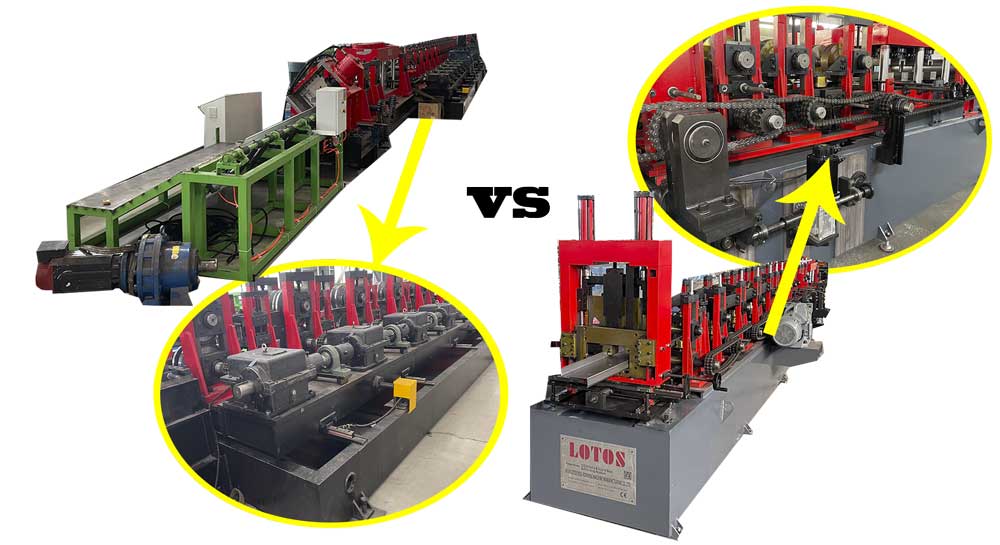

in truth, This Fully automatic purlin making machine uses the same set of equipment to produce all the specifications in the C and Z Galvanised Steel Purlins plate type drawing, and the C specification conversion is completely automatic, and the operation is convenient and fast. Specifically, The structural design of the coaxial sliding sleeve eliminates the old cantilever unilateral forming unit and solves the problems of the insufficient structural strength and speed difference, and deviation. moreover, The control system is completed by an industrial PLC and auxiliary electrical components, and a human-computer interaction interface. the production efficiency is high, the specification adjustment can be completed in a few seconds, and the control system automatically adjusts as long as the parameters are input on the display screen.

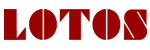

Purlin Roll Forming Line

Machine Design Capacity Purlin Roll Forming Machine

- Raw material thickness: 2.0-3.2mm

- Input material width: waist height 50-80mm, bottom width 80-300mm

- Raw material yield limit: 550MPA

- Production line working speed: 0-18m/min

- Machine power: 30 kW

Machine components :

This purlin making machine will be combined with an automatic manual decoiler and leveling system, and servo feeding device, and punch machine with dies, and roll-forming machine part, and hydraulic cutting unit, an output table, and hydraulic oil pump, and electrical control cabinet and so on.

Cutting Device :

The cutting mold frame adopts the gantry type and is made into a whole. According to the length parameter of the input workpiece, after using the encoder to lengthen.

After the encoder is fixed in length, it will automatically stop and cut off.

(1) Cut mode: This machine adopts the front cut mode.

(2) The hydraulic shear type is adopted, and the workpiece is effectively cut to a width of 600 mm. Shear thickness: 1.5 mm.

(3) Scissors material: Cr12, and quenched. The quenching hardness is reached (HRC 58-62 degrees).

(4) Install the material guide plate and the discharge plate before and after the shearing, structure to ensure smooth material in and out.