Storage Rack Roll Forming Machine

- Home

- Storage Rack Roll Forming Machine

Slide 2

Slide 3

Slide 4

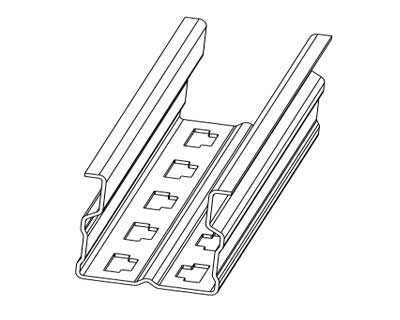

Rack Roll Forming Machine

Before speaking about Storage Rack Roll Forming Machine we should know, Pallet racking systems are material handling storage aid systems designed to store materials on pallets. however, there are many types of pallet racking, all types allow for the storage of palletized materials in horizontal rows with multiple levels. storage Pallet racks are very managed storage systems, designed for rapid construction, adjustability, and re-use. Pallet racking is usually comprised of beams, wire decks, and uprights.

Most common types of pallet racking systems:

- Cantilever Racking

- Selective Racking

- Push Back Racking

- Drive In Racking

- Pallet Flow Racking

- Carton Flow Racking

- Mobile Rack or Mobile Sliding Rack

- Double deep racks

- Push back rack

- Pallet flow rack

Storage Rack Upright Roll Forming Machine

LOTOSFORMING Upright Roll Forming Machine is suitable to form galvanized and CS Stainless steel and copper and so on. Most customers place orders for galvanized and carbon steel that for business construction is more popular.

Rack Column Roll Forming Machine drives by gearbox and electronic motor to make sure your thick hard material can form standard And roller installs on 80 mm diameter shaft for long time usage by various forming speed.

in fact, LOTOSFORMING has already manufactured and installed more than 100 complete lines of STORAGE RACK ROLL FORMING MACHINE around the world successfully. For getting more knowledge about this machine watches our video on the youtube channel And also feel free to send your inquiry to us by email.

Storage Shelves Roll Forming Machine

LOTOSFORMING is one of the leading racking making machine manufacturers in the racking industry of China, and specialized in the design, manufacture the roll forming machines.

1)Production working flow

Manual decoiler→leveling—>Mechnical Press Machine with Punch DIE→roll forming machine→shape cutting→output table

2) Machine design capacity

- Raw material thickness: 2.5mm

- Input material width: 160mm

- Raw material yield limit: C.S, galvanized steel

- working speed without punching: 15-20m/min

- Working area: about L6,000*W600mm*H1,200mm

- Machine G.W: 15,000KGS

3) Machine components

This production line will be combined with a manual decoiler and leveling system, mechanical press machine with punch die and roll forming machine part, output table, hydraulic pump station, and electrical control cabinet, and so on.

4) Each part technical parameter

| 1. Manual decoiler | ||

| 1.1 | Loading capacity | 5T |

| 1.2 | Steel coil I.D. | φ480-φ508mm |

| 1.3 | Steel coil O.D | max φ1800mm |

| 1.4 | Cantilever width | 500mm |

| 2. Leveling System | ||

| 2.1 | Roller number | 7 pcs |

| 2.2 | Motor | 4KW |

| 3. Mechanical Press Machine | ||

| 3.1 | Puncher machine | YANGLI |

| 3.2 | Press power | Mechanical 80T |

| 3.3 | Punch Die Material | Gcr12, heat treatment, Hardness 58-62° |

| 3.4 | Puncher die | 1 set |

| 4. Roll Forming Machine | ||

| 4.1 | Roller groups | 18 stations |

| 4.2 | Roller material | GCr15 with heat treatment, HRC58-62° |

| 4.3 | Roller shaft dia. | Φ80mm |

| 4.4 | Shaft material | 45# with quenching and tempering |

| 4.5 | Motor | 18.5KW |

| 4.6 | Transmission way | Gearbox ( Chain available) |

| 4.7 | Machine frame body | 8mm Welded plated, Stress-Relieving |

| 4.8 | Roller supporter | nodular iron casting pillar |

| 4.9 | Roller bearing | HRB, 30213 |

| 5. Hydraulic Pump Station | ||

| 5.1 | Motor power | 4KW |

| 5.2 | Cooling way | Fan wind |

| 6. Electricity control cabinet | ||

| 6.1 | Frequency inverter | DELTA |

| 6.2 | PLC | DELTA |

| 6.3 | Screen touch screen | DELTA |

| 6.4 | Encoder | Omron |

| 6.5 | Low voltage | Schneider |

| 7. Cutting precision | ||

| 7.1 | Cutting length | ±1.0mm |

| 7.2 | Vertical Tolerance | ±1.5mm |

| 7.3 | Horizontal tolerance | ±1.5mm |