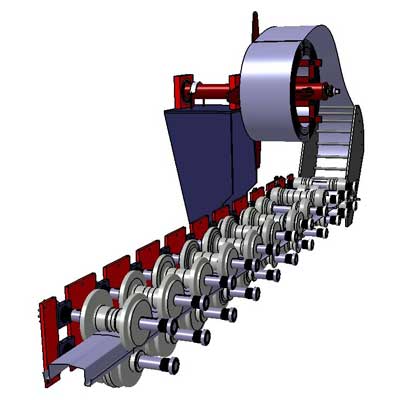

Cold Roll Forming Technology

Advantages of Cold Roll Forming:

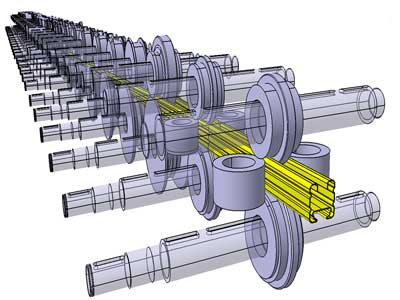

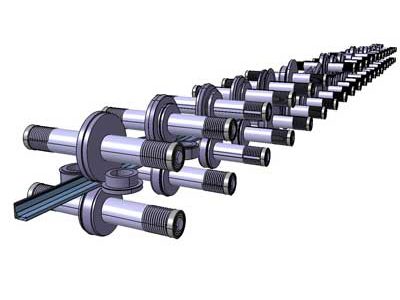

Cold roll forming technology offers exceptional precision and consistency. The use of multiple rollers ensures that the steel profile is shaped accurately and uniformly along its entire length. This precision is critical for applications where exact dimensions are necessary.

Materials and Design Versatility in Cold Roll Forming:

This method is highly efficient and cost effective. By continuously forming the steel strip, cold roll forming minimizes downtime and increases production speeds. Additionally, the process reduces material waste, contributing to overall cost savings.

Cold roll forming is versatile, capable of producing a wide range of profiles with varying complexities. The adaptability of the roller shapes and numbers allows manufacturers to meet diverse industrial requirements, from simple channels to intricate structural components.

Applications of Cold Roll Forming:

Cold roll forming is widely used in numerous industries, including construction, automotive, aerospace, and manufacturing. It is essential for creating components such as:

Future Trends in Cold Roll Forming Technology:

One of the emerging trends in cold roll forming technology is the use of advanced materials. Manufacturers are exploring the integration of high strength steels, aluminum alloys, and composite materials into the cold roll forming process. This trend aims to enhance the performance characteristics of the formed profiles, such as improved strength-to-weight ratios and corrosion resistance.

Automation and Digitalization in Cold Roll Forming Processes:

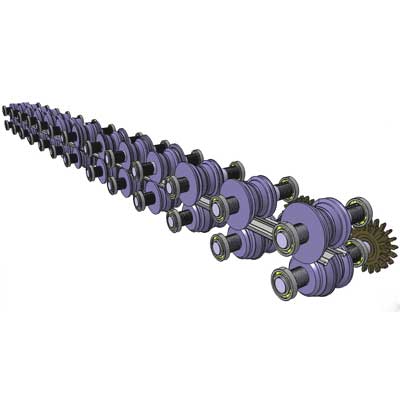

Automation and digitalization are transforming cold roll forming operations. Advanced control systems, robotics, and real-time monitoring technologies are being integrated into production lines to optimize efficiency, reduce downtime, and enhance quality control. Digital twins and simulation software are also becoming instrumental in predicting and optimizing the forming process parameters.

Sustainability is a growing concern across industries, and cold roll forming is no exception. Manufacturers are increasingly adopting sustainable practices in their processes, such as using recycled materials, optimizing energy consumption, and minimizing waste generation. Cold roll forming’s inherent efficiency and material utilization contribute to its eco-friendly profile compared to other forming methods.

Consumer demands for customized products are driving the need for greater flexibility in cold roll forming technology. Manufacturers are developing modular tooling systems and flexible production setups that can quickly adapt to produce different profiles with minimal changeover time. This trend enables more agile manufacturing processes and supports rapid product innovation.

Sustainability is a growing concern across industries, and cold roll forming is no exception. Manufacturers are increasingly adopting sustainable practices in their processes, such as using recycled materials, optimizing energy consumption, and minimizing waste generation. Cold roll forming’s inherent efficiency and material utilization contribute to its eco-friendly profile compared to other forming methods.

Consumer demands for customized products are driving the need for greater flexibility in cold roll forming technology. Manufacturers are developing modular tooling systems and flexible production setups that can quickly adapt to produce different profiles with minimal changeover time. This trend enables more agile manufacturing processes and supports rapid product innovation