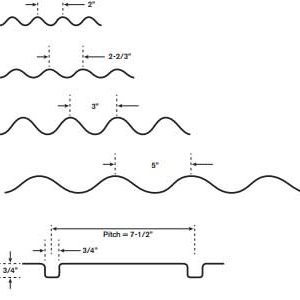

Spiral Corrugated pipe making machine

Corrugated steel pipe (CSP) has been used for more than 100 years in the critical storm sewer and culvert applications and was available only as a galvanized coated steel pipe for the first half of this period.

With the addition of new material options over the past 50 years, including new high-performance coatings, CSP has increased its value and usefulness in providing extended service life over a broader range of environmental conditions.