Roll Forming Machine Part-Spacers and Shims

Horseshoe Spacers:

Horseshoe spacers were among the first quick removal spacers developed by the industry. This type of spacers, as well as the horseshoe shims, create considerable problems. The “open” sections of all horseshoe spacers are in the same direction. In the case of small shaft diameters (1 to 1.5 in), the forces applied by overtightening the nuts at the end of the shafts can bend the shafts. The continuous flexing of the shafts at each revolution can create another problem. The top roll spacers (and the shims) can fall out and damage the next pass rolls. Therefore, manufacturers use spring-loaded ball locators to hold the horseshoe spacers in position. However, it is highly recommended not to use horseshoe spacers at all.

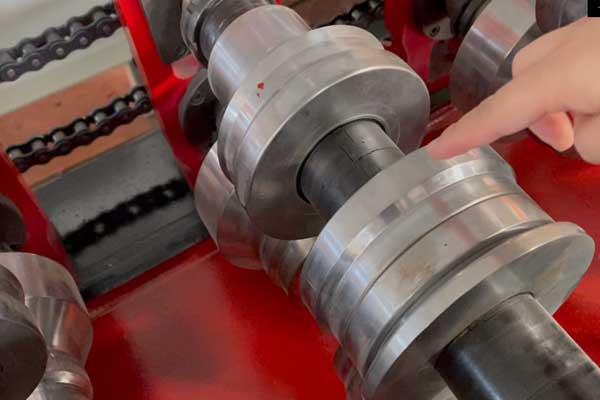

Bolted and Hinged Split Spacers:

Bolted spacers have been used to avoid accidental falling of spacers from the shafts. These spacers will not fall out but the removal of the screws or other fasteners takes too much time. Hinged spacers somewhat reduce the time required to remove and install these bolted-type spacers.

Boltless Spacers:

A variety of boltless, quick removal spacers has been developed and successfully used. The removal and reinstallation of such split spacers may take less than 1 min after the operator-side stand is pulled out by a short distance.

Split spacers are more expensive than one-piece spacers, but the extra cost can be quickly recovered by reducing the nonproductive time.