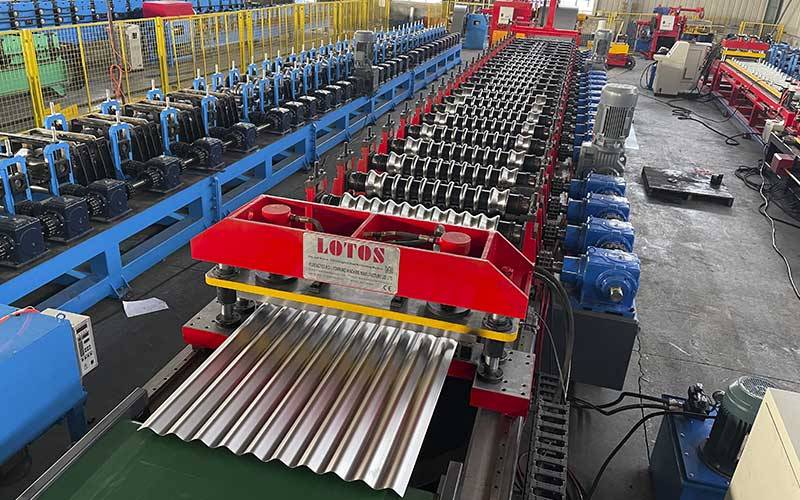

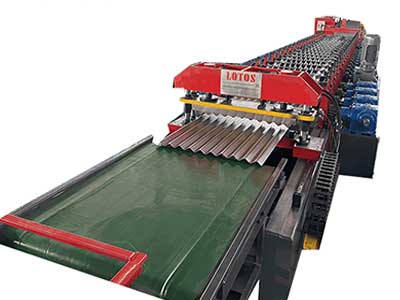

corrugated metal roofing sheets have durability because of their special corrugated shape. in addition, The natural shape of corrugated metal roof panels gives it a structural advantage over other panels of the same material. the color-coated roofing sheets can hide small imperfections over time from weather or impacts. LOTOSFORMING ▷ Corrugated Roll Forming Machine | Corrugated Metal Roofing 2022 ◁ is specifically designed for rolling galvanized also pre-painted and Galvalume steels into corrugated roof sheets.

Corrugated Roof Sheeting Machine