We have Roofing Sheet Making Machine. Metal roof sheets are an affordable option, able to withstand high temperatures. for this purpose, LOTOS roofing roll former offers to you Roofing Sheet Making Machine and Roof Panel Roll Forming Machine. in addition, A rolled metal roofing is lighter than a concrete or clay tile roof more durable than an asphalt shingle roof, and easier to handle than long-run metal roof tiles. furthermore, It is the best reliable and affordable roofing system in the marketplace in a range of designs and styles. moreover, Roof tiles can now mimic other roofing materials such as wood shake asphalt shingles, and slate, however, the metallic look often compromises the authenticity of these renditions and the overall design.

meanwhile, Our ▷ Roofing Sheet Making Machine | Rolled Metal Roofing 2022 ◁ offers a diverse range of solutions to architects and building designers looking for differentiated facade and metal roofing applications. finally, Contact Us To Get More Information About Our panel roll forming machine. in truth, We offering you an outstanding quality range of, machines to make metal roofing.

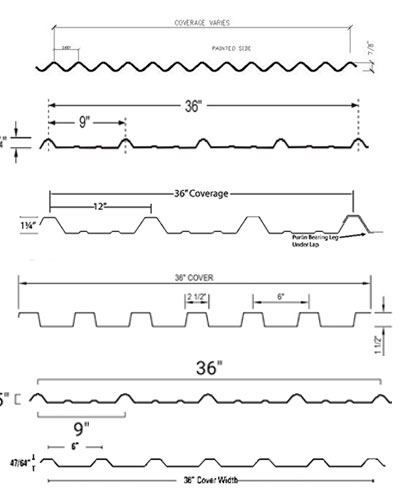

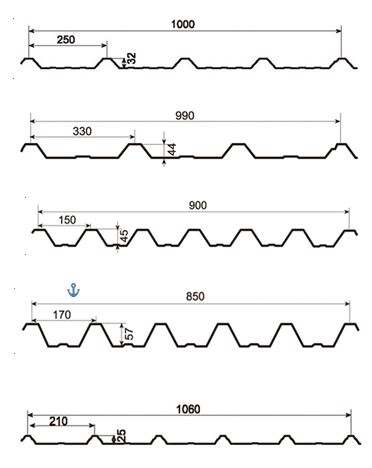

Types of metal roofing panels :

Therefore, the LOTOSFORMING group introduces all kinds of roofing sheets and wall panels to you. you can see the following videos and know all of the roof tile panel and wall tile panel including:

- r panel profile

- u panel profile

- TUFF-RIB PANEL profile

- Box Rib PANEL profile

- AG metal PANEL profile

- Corrugated PANEL profile

- STANDING SEAM METAL ROOFS profile

- batten style panel profile

- GLAZED TILE profile

- Belvedere Plenum Wall panels

- Grand V panels / Grand C panels

- SPAN WALL PANEL profile