Product description

Performance Capabilities and Machine

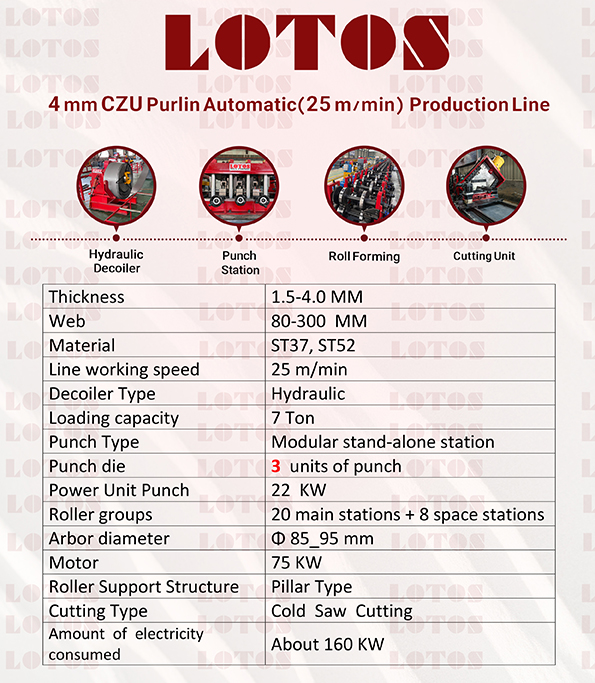

Specifications This production line has been engineered to deliver maximum stability, durability, and precision. It is designed to process ST37 and ST52 steel coils with a thickness range of 1.5 to 4.0 mm, producing profiles with a web size of 80–300 mm and flange size of 30–80 mm, making it suitable for a wide range of industrial applications. The leveling unit features a 2 roller feeding system combined with 5 roller leveling to ensure excellent flatness and consistency of the incoming strip. For punching operations, the line is equipped with 3 independent punch stations on an isolated punch frame, allowing high precision punching patterns.

The power transmission relies on a gearbox system, while the machine body is built on an integrated welded frame with precision milling. The roller supporters are made from casting pillar stands, ensuring rigidity and stability even under heavy duty production.Thickness adjustments are managed through a manual interchange tooling system, providing flexibility for different profile dimensions. Finally, the line is equipped with a servo tracking cutting system (non-stop), ensuring continuous production with accurate and clean cuts at high speed.

working flow:

Hydraulic Decoiler+Loading Cart → Looper 1# → Servo Feeding+5-roller Leveling +Hydraulic Punch Station (3 units of punch seats) →Looper 2# → Roll Forming Machine → Servo Tracking Cutting Die → Out-put table

FAQ:

1. Is maintenance and servicing of this machine straightforward, or does it require skilled technicians?Daily maintenance is simple, but specialized care for dies and rollers requires trained technicians.

2. Can additional automation for punching or cutting be integrated into the line?Yes, the design allows adding options like extra punching units or advanced cutting systems.

3. What measures are in place to minimize vibration and noise during operation?The integrated welded frame and cast pillar stands minimize vibration and noise, ensuring stable and safe operation.

Reviews

There are no reviews yet.