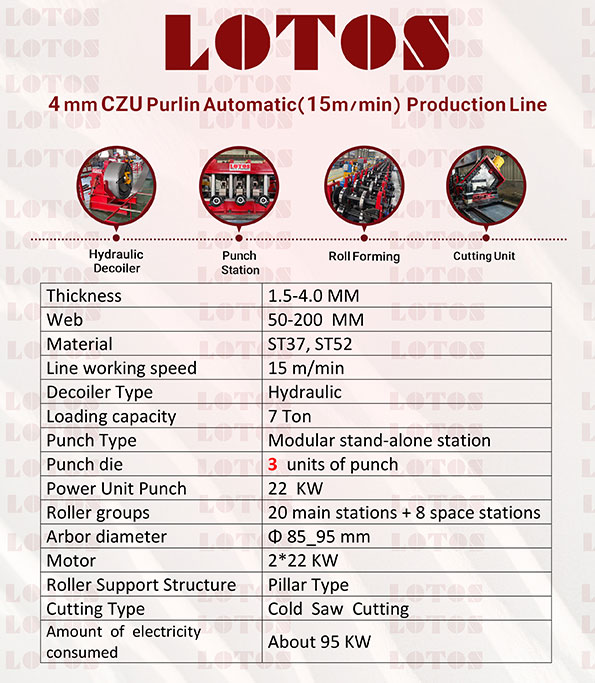

Product description

Performance Capabilities and Machine

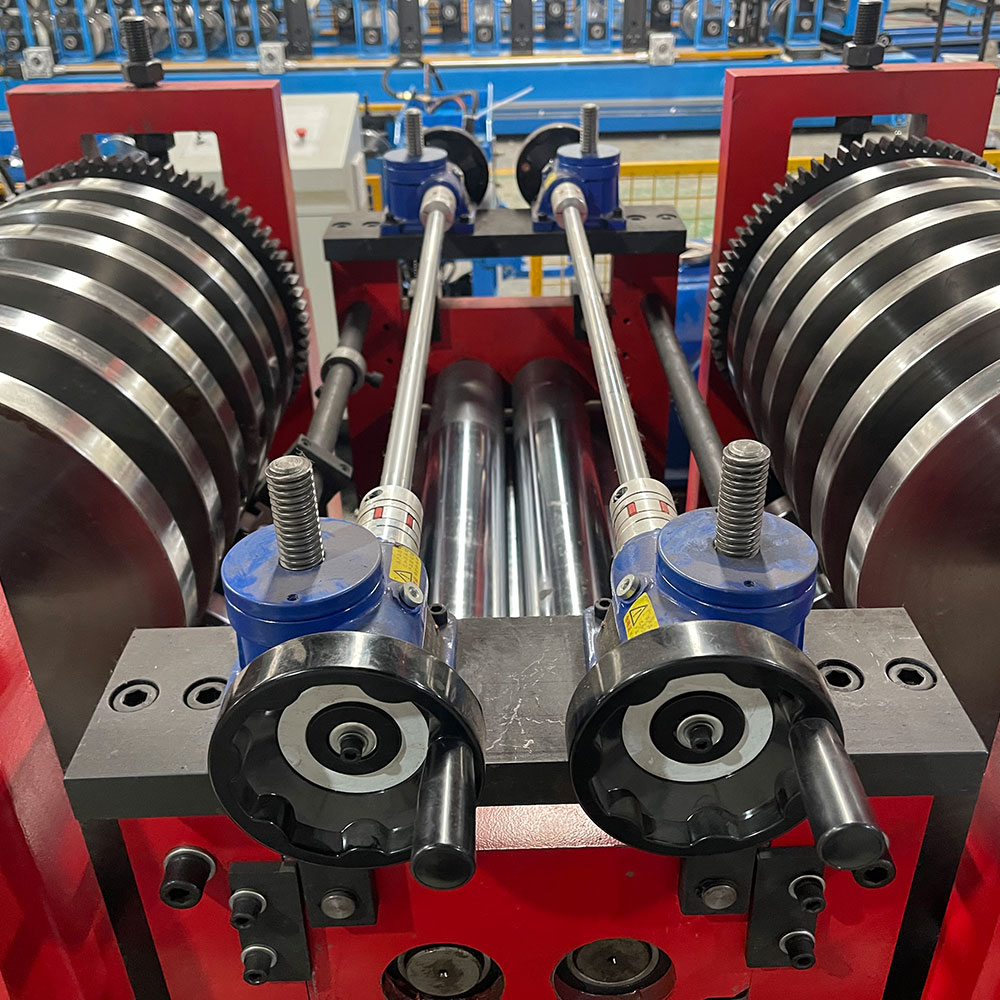

Specifications This CZU production line features engineering-precise design with gearbox transmission and an integrated frame ensuring full stability. Roller supports are made of cast steel, and the manual tooling system allows quick thickness changes.The hydraulic punch station with 3 independent CR12MOV dies ensures high accuracy. Motorized unwinding with hydraulic expansion provides smooth operation, while the servo tracking cutting die enables nonstop cutting. Coupled loading cart, disc brake, and pneumatic press arm ensure safe and efficient performance.

working flow:

Hydraulic Decoiler+Loading Cart → Looper 1# → Servo Feeding+5-roller Leveling +Hydraulic Punch Station (3 units of punch seats) →Looper 2# → Roll Forming Machine → Servo Tracking Cutting Die → Out-put table

FAQ:

1.Does the system come with PLC and touch screen control?Yes, the production line is equipped with an electrical control cabinet featuring a DELTA PLC and DELTA touch screen, providing easy operation and precise machine control.The system includes a DELTA frequency inverter and Schneider low voltage components, and can operate with 380V/50Hz/3P power supply or customized options.

2. What infrastructure, such as power and hydraulic system, is required ?The production line requires a 380V, 50Hz three-phase power supply, which can be customized according to the customer’s needs. It also includes a hydraulic system for the punch station and hydraulic roll arms, ensuring smooth and precise machine operation.

3.How automated is the line, and which parts require an operator?The CZU production line is highly automated, featuring servo feeding, hydraulic punch station, roll forming, and nonstop servo cutting. However, an operator is required for tooling adjustments when changing material thickness, monitoring production, and overall safety control.

Reviews

There are no reviews yet.