Box Board Roll Forming Machine

- Home

- Box Board Roll Forming Machine

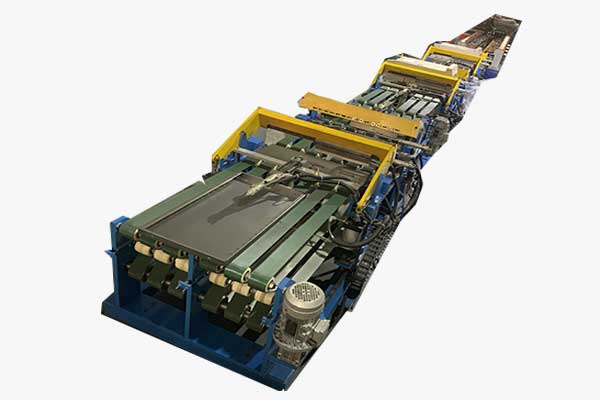

Supermarket Shelf Panel Roll Forming Machine

The full production line includes:

- supermarket shelf board machine

- backboard supermarket shelf machine

- tube punching machine

Roll forming Machine is also used in the Supermarket Shelving System industry. Most of the metal products of the storage system can produce by metal roll forming machine including supermarket shelf board, backboard supermarket shelf, and tube punching.

Supermarket Shelving Panel Machine

Supermarket Shelf Panel Making Machine

- Summary box panel roll forming machine

- Raw material thickness: 0.5-1 mm

- Material: G350Mpa cold rolled or hot rolled steel, galvanized steel

- Input material width: depends on the size

- Production line working speed: 6-8m/min

- Working area: about L15,000*W2,000mm

- Main parts

This Box Board roll forming machine or Supermarket Box Board Roll Forming Machine production line will be combined with a hydraulic decoiler, servo feeding device and, hydraulic punch machine with dies and, roll forming machine part and, output table, hydraulic oil pump, and electrical control cabinet, and so on.

Technical data Supermarket Shelf Panel Roll Forming Machine

Shelf panel making machine is able of producing shelf panels up to customized measurements as required. Roll forming stands move through the linear guide to adjust the gap between rollers for producing different sizes of panels.

- Decoiler:

| type | hydraulic |

| Loading capacity | 5Ton (Impassive to expanding) |

| Steel coil I.D. | φ480-φ520mm |

| coil O.D | max φ1800mm |

- Servo feeding system:

| Drive | DELTA |

| Power | 2KW |

- Punching station:

| Perforated unit | One unit of the cantilever (2 sides for waist hole) |

| Press power | hydraulic |

| Punch Die Material | Cr12Mov, heat treatment, Hardness 58-62° |

- Roll forming system with feed panel:

| Roller groups | 15 stations |

| Material | GCr15 with heat treatment, HRC58-62° |

| Roller shaft dia. | Φ60mm |

| Shaft material | 45# Steel with quenching and tempering |

| Motor | 4 KW Servo motor |

| Transmission way | Chain with automatic changeable size |

| Machine frame body | Welded |

| Roller supporter | Wall panel |

| bearing | HRB, NU1108 |

| Automatic moving motor | 1.5KW * 4 sets |

- Electrical system:

| PLC system | DELTA |

| Length Controller | Encoder |

| Operation | Touch Screen DELTA |

| Inverter | DELTA |

| Voltage | 380V/50Hz/3P |

Don’t forget subscribe to our youtube channel :

FAQ :

A Box Board Roll Forming Machine is a specialized production line used to manufacture metal box boards and structural panels with high precision and strength for industrial and commercial applications.

The machine typically processes galvanized steel, cold-rolled steel, and pre-painted steel coils, ensuring durable and corrosion-resistant box boards.

Box boards are widely used in construction, transportation, warehouse storage systems, enclosures, and electrical cabinet manufacturing.

The line usually includes a decoiler, leveling system, punching station, roll forming unit, hydraulic cutting system, and automatic stacking.

High speed and continuous production

Uniform product quality and accuracy

Cost effective and energy-efficient

Customizable sizes and shapes