Cable tray machine

Cable Tray Roll Forming Machine

- Home

- Cable Tray Roll Forming Machine

Cable tray machine

Roll Forming Systems for Cable Trays

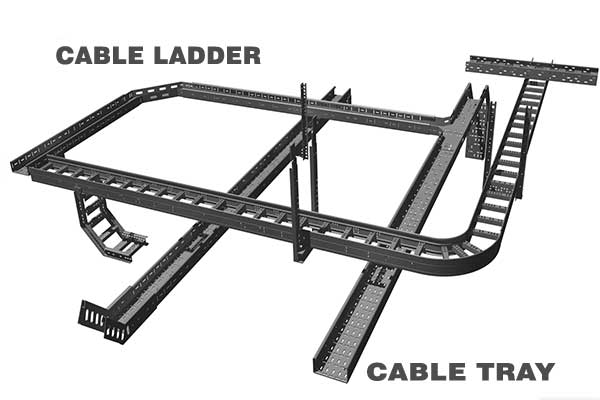

A cable tray system used to support insulated electrical cables used for power distribution control and communication as an alternative to open wiring or electrical conduit systems. In addition, Cable tray systems are the right solution for running large quantities of data cables overhead or under-floor. so, these systems are known as baskets, trunking, or cable ladders.in fact, Our full line of ▷ Cable Tray Roll Forming Machine | Cable Tray applications ◁ are available on the youtube channel and can be accessed by clicking LOTOS Cable Tray YouTube.

At Lotosforming, we aim to be the leading provider of information and solutions for design and engineering professionals engaged in the design of cable tray roll forming machines. Furthermore, our full line of Cable Tray Roll Forming Machines and applications is showcased on our YouTube channel.

Multi Size Cable Tray Roll Forming Machine

Our latest version of the multi-size cable tray roll forming machine can produce various lengths and heights, suitable for thicknesses of 1.2-2 mm. With extensive experience in different punching designs, we cater to the diverse demands of different industries, providing flexible and precise solutions.

At Lotosforming, we specialize in designing and manufacturing state of the art roll forming machines, including those used for producing cable trays. Our machines are highly efficient, utilizing a continuous forming process that ensures consistent quality and the ability to create complex profiles.

What are Cable Trays?

Cable trays are essential structures used to support insulated electrical cables for power distribution, control, and communication. They serve as an efficient alternative to open wiring or electrical conduit systems, providing a secure pathway for cables in various environments. Cable trays are ideal for running large quantities of data cables overhead or under-floor and are commonly referred to as baskets, trunking, or cable ladders.

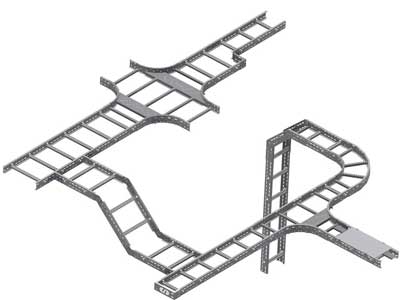

Types of Cable Trays

We offer a variety of cable trays to meet different needs:

- Ladder Type Cable Tray

- Solid Bottom Cable Tray

- Trough Cable Tray

- Channel Cable Tray

- Wire Mesh (Basket) Cable Tray

- Single Rail Cable Tray

- Fiberglass Cable Tray

- Perforated Cable Tray

Ladder Cable Tray Machine

- Solid side rail protection and system strength with smooth radius fittings and a wide selection of materials and finishes.

- maximum strength for long-span applications with standard widths of 150, 300, 450, 600, 750, and 900 millimeters.

- standard depths of 50, 75, 100, 125, and 150 millimeters.

- the standard lengths of 3 to 6 meters.

- the rung spacing of 150, 225, 300, and 450 millimeters.

- A ladder cable tray is generally used in applications with intermediate to long support spans, 3 meters to 6 meters.

Solid Bottom Cable Tray Machine

- Non ventilated continuous support for delicate cables with added cable protection available in metallic and fiberglass.

- Solid bottom metallic with solid metal covers for non-plenum-rated cable in environmental air areas.

- standard widths of 150, 300, 450, 600, 750, and 900 millimeters.

- the standard depths of 75, 100, 125, and 150 inches

- standard lengths of 3, 6, meters Solid Bottom cable tray is generally used for minimal heat generating Electrical or telecommunication applications with short to intermediate.

Trough Cable Tray Machine

- Moderate ventilation with added cable support frequency and with the bottom configuration providing cable support every 4 inches. Available in metal and nonmetallic materials.

- standard widths of 150, 300, 450, 600, 750, 900 millimeters

- the standard depths of 75, 100, 125, and 150 millimeters.

- standard lengths of, 3000, 6000 millimeters.

- fixed rung spacing of 100 millimeters on center Trough cable tray is generally used for moderate heat generating applications with short to intermediate support spans of 0.6, 3, 6 meters.

Channel Cable Tray Machine

- economical support for cable drops and branch cable runs from the backbone cable tray system.

- the standard widths of 75, 100, and 150 millimeters in metal systems and up to 200 millimeters in nonmetallic systems.

- standard depths of 30 to 50 millimeters in metal systems and 25, 30, 40, and 50 millimeters in nonmetallic systems.

- the standard length of 3, 4, and 6 meters Channel cable trays are used for installations with limited numbers of tray cables when the conduit is undesirable. Support frequency with short to medium support spans of 1.5 to 3 meters.

Cable trunking machine

Cable trunking use to protect cables from hurt.in fact, Cable Trunking and protects your electrical cables from damage. Trunking is usually square or rectangular in shape and provides easy access to the cable when needed via a hinge or slide system.

Perforated Type Cable Tray Machine

Perforated cable trays feature uniform holes that offer effective ventilation and protection for cables against external damage. Manufactured from galvanized iron or mild steel, these trays are widely used across various industrial sectors for reliable cable management solutions.

Modern perforated cable tray roll forming machines are designed to meet diverse production requirements, with the flexibility to customize sizes and specifications. An essential feature of these machines is the integrated quick fastening system, which enables fast, secure assembly of cable trays without the need for screws or additional tools. This system not only simplifies installation but also significantly reduces labor costs and enhances overall project efficiency.

With high precision, durability, and advanced technology, these machines ensure consistent quality and performance, making them ideal for a wide range of industrial applications. The ability to produce high-quality perforated cable trays with minimal effort makes them an indispensable asset in today’s electrical and construction industries.

Din rail channel machine

A DIN rail functions as a mechanical support structure for various types of small electrical components. A DIN rail is a metal rail of a standard type widely used for mounting circuit breakers and industrial control equipment inside equipment racks.

Cable Tray making machine

Cable tray design size:

Height: 50-200mm

Width: 100-800mm

Thickness: 2.0mm

Machine design capacity

- Raw material thickness: 0.7-2.0mm

- Material: Galvanized, Carbon Steel, HR coils

- Input material width: depends on cable tray size

- Raw material yield limit: 245MPA

- Production line working speed: 6-8m/min

- Working area: about L40,000*W4,000mm

- Machine components

This cable channel production line will be combined with automatic hydraulic decoiler, leveling system, hydraulic punch machine with dies, roll forming machine part, hydraulic cutting unit, output table, hydraulic oil pump, and electrical control cabinet and so on.

Each part technical parameter

| 1. Automatic hydraulic decoiler | |||||||

| 1 | Loading capacity | 8T | |||||

| 2 | Steel coil I.D. | φ480-φ520mm | |||||

| 3 | coil O.D | max φ1800mm | |||||

| 4 | Cantilever width | 1250mm | |||||

| Feature: With hydraulic expansion, it can adjust to coil inner diameter during produce. | |||||||

| 2. Perforating station | |||||||

| 1 | Perforating sets | 2 sets | |||||

| 2 | Die qty | 4 sets | |||||

| 3. Roll Forming Machine | |||||||

| 1 | Roller groups | 23 stations | |||||

| 2 | material roller | GCr15 with heat treatment, HRC58-62° | |||||

| 3 | Roller shaft dia. | Φ85mm | |||||

| 4 | Shaft material | 45# Steel with quenching and tempering | |||||

| 5 | Motor | 5.5KW+11KW | |||||

| 6 | Transmission way | Chain with automatic changeable size | |||||

| 7 | Machine frame body | Welded by 500BH H-beam, Stress-Relieving | |||||

| 8 | Roller supporter | duplex | |||||

| 9 | bearing | HRB, NU1108 | |||||

| 10 | Automatic moving motor | 1.5KW * 4 sets | |||||

| 6. Hydraulic cutting unit | |||||||

| 1 | Cutting way | Stop cutting | |||||

| 2 | Length measure | Encoder with Borescope instrument | |||||

| 3 | Cutting die | Cr12MoV with quenching treatment | |||||

| 4 | Die unit | Combination die | |||||

| 7. Hydraulic Pump Station | |||||||

| 1 | Motor power | 22KW | |||||

| 2 | Cooling way | Fan wind | |||||

| 8. Electricity control cabinet | |||||||

| 1 | Frequency inverter | YASKAWA | |||||

| 2 | PLC | Siemens | |||||

| 3 | Screen touch screen | Beijing MCGS 10inch | |||||

| 4 | Low voltage | Schneider | |||||

Cable Tray production line

hydraulic decoiler:

- Width of material:max 1000mm

- hydraulic inner expansion and motorized decoiling

- The inner diameter of the coil: φ508mm

- inner expansion range: ф460-520 mm

- Outer max. diameter: φ1500mm

- Decoiling speed:15-20m/min

- Max. loading capacity: ≤5T

- Motor:5.5kw made in China

- DELTA inverter made in Japan

Cable Tray forming machine

Cable Tray and Fittings system

Guiding, feeding, and leveling

- We adopt 2 pinch rolls and 11 rolls leveling ( upper 5 rolls and bottom 6 rolls)

- Pinch rolls and leveling rolls material:40Cr,quenched,heat treatment, HRC55–58,Pinch rolls diameter 96mm,leveler rolls diameter 64mm

- Leveling rolls width:max 800mm

- Materials thickness:0.5–2.5mm steel grade G350Mpa

- Motor power:7.5kw made in China

- A way of a drive: gear drive

- Upper leveling rolls are adjusted by the screw rod with measures meter

- The press button “start” and “stop”

- Voltage requirements:380V,50Hz,3Ph

Servo feeder system:

- Servo-feeder model: SRF-800B

- Function: For material feeding into the press punching machine

- Feature: Uses servo motor-driven.

- capability Feeding :width800mmx0.5-2.8mm coils

- Feeding speed: max 20m/min

- accuracy Feeding:≤±0.1mm(within200mm)≤±0.2mm(within 500mm)

- Max feeding step distance:≤9999.99mm

- Feeding rolls diameter:2-Φ95mm, we adopt rubbers as upper rolls, bottom rolls material is 40Cr, high-frequency tampered treatment, HRC55-58, chrome on the surface

- Pneumatic style to tighten or relax

- Air supply:0.5Mpa

- Multistage type feeding: May input various groups of different feeding lengths. The liquid crystal touching screen demonstrated is advantageous for the change, establishes various technical parameters. The auto-induction start system and the punch press linkage (control punch press start).

- It will be installed on the side of the pressing machine

Cable Tray Punching Machine

- Model of punching press: JF21-315T

- Punching press: Uses the steel plate welding fuselage, the rigidity is strong with a good appearance.

- Uses the combined type of air-operated friction clutch.

- punched 25-35 times per min

- Worktable size:max 1000mm

- thickness Worktable:180mm

- Motor power:15kw

- Weight:18,000kgs

Lateral holes and width holes punching:

- Punching mold material: Cr12 Mov, HRC58-62

- The holes size can be adjustable and the punching head is controlled by the cylinders.

- There are totally 1 set of punching mold

Cable Tray Machine

Main Forming Machine:

- We adopt a casting pillar type machine structure and one size of the roller stands can be adjusted and controlled by PLC and the other side is fixed

- 14 forming stands plus 4 vertical rolls

- Motor power:15kw made in China

- Material max. thickness:0.7-1.2mm

- The diameter of the shaft: ¢80mm

- Rollers material: GCr15 quenching treatment: HRC58-62°

- The material of shaft:40Cr heat treatment

- Driving system: chain drive 1.2”

- Line speed:3-5m/min

- With fully automatic adjustment from one width to another width, it just needs a few seconds to finish changing

- Finished cable tray length precision:±3mm/10m

- straightness precision: ±1-1.5 degree /10m

- The line will be painted industrial blue or green color as picture below or the color provided form the Buyer

- cable tray length Finished:2-10m

Hydraulic Cutting unit:

- A way of cutting: we adopt hydraulic post-cut after forming

- The material of blade: Cr12Mov, quench treatment, hardness HRC58-62

Run out table:

- Structure: roller type with no power

- 2 pcs

A hydraulic control system (LOTOS standard):

- We adopt the separate hydraulic oil tank outside of a line

- Hydraulic station power: 7.5kw

- We adopt famous brand solenoid made in China

- N45 or N46 hydraulic oil is available

Cable Tray Machine Manufacturer

Electric control system:

- The full line is controlled by the PLC control system(Siemens brand),touch screen operation to achieve the human and PLC interactive. The operator can monitor the setting program (programmable control)and modify the para5meter to control the line. Also can check the running status, parameter and error indication, etc.

- Operation type: manual /auto two type switch. In manual position: can run each part of the machine. In auto position: can run the full line. The emergency stop ensures the safety of the equipment and operator.

- The machine side is equipped with a manual operation control panel for a convenient worker to operate.

- Entire line surveillance function: to reach surveillance production line movement condition, realizes to various locations production condition surveillance.

- Has the failure detection function: Carries on to the production line signal succession examines, the checkup according to sequence, discovers the mistake, and gives the alarm to stop the machine.

FAQ:

1. What is a Cable Tray Roll Forming Machine?

A Cable Tray Roll Forming Machine is a high-performance production line designed to manufacture metal cable trays used for supporting and organizing electrical cables in industrial and commercial buildings. It forms steel coils into perforated or solid cable trays with precise dimensions and strong structural integrity.

2. What materials can be used in cable tray production?

LOTOSFORMING machines can process galvanized steel, stainless steel, pre-painted steel, and aluminum coils, typically ranging from 0.6 mm to 3.0 mm in thickness.

3. What are the main types of cable trays produced by the machine?

The system can produce various styles such as:

Perforated cable trays

Ladder type cable trays

Solid-bottom cable trays

Wire mesh type (optional)