DOUBLE LAYER FORMING MACHINE

Double Layer Forming Machine

- Home

- Double Layer Forming Machine

DOUBLE LAYER FORMING MACHINE

Double Layer Roof Panel Roll Forming Machine

Our introduced roll forming machine is manufactured by LOTOS professionals using high-grade components and the latest technology in compliance with the industry quality standards. So, we are employed in supplying a wide range of ▷ Double Layer Forming Machine | Custom DESIGN 2025 ◁.

we can produce any type of metal roofing sheet or wall panel or corrugated sheet in an Automatic double layer roof panel roll forming machine according to customer requirements such as :

- Roof Tile & Corrugated roll forming machine

- wall tile & Corrugated making machine

- Roof Tile & wall tile production line

- double roll forming machine

- 2 IN 1 roll forming machine

Steel double layer roll forming machine

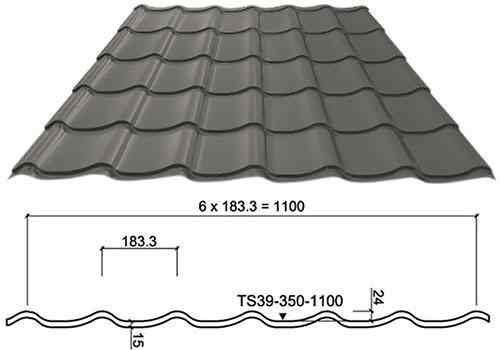

A double layer roll forming machine designed to produce two different kinds of metal sheets such as :

- trapezoidal roofing sheet and corrugated roofing sheet

- trapezoidal sheet and metal roof tile

- corrugated sheet and metal glazed roof tile

It is necessary to be noticed the double layer roll forming machine cannot run at the same time. because one PLC control system restores the specifications for one type of sheet, like cutting length and production quantities. The double-layer roll forming parts share the same motor and the change of running between the top and bottom roll forming part is made through a clutch aimed at this double layer machine.

Double Deck Roll Forming Machine

1) Summary

- Material: Galvanized Coil, Color steel coil

- Material Thickness:0.4-0.6mm

- Main roll forming machine Power: 7.5 KW*2 sets, Siemens

- Input width:1250/1000mm

2) Main Parts

- Manual Decoiler

- Manual pre-shearing

- Feeding Guide

- Roll Forming System

- Hydraulic Stamping&Cutting unit

- Control system

- Output table

3) Working Flowing

Manual Decoiler— Feeding—Roll Forming—-Hydraulic Stamp & Cutting —- Output table

| Decoiler |

| Decoiler Type | Manual |

| Loading capacity | 5Ton Impassive to expanding |

| Roll Forming system with feed panel unit |

| Axis Diameter | 75mm |

| Forming Roller station | 18 Groups |

| Main Axis material | First grade 45# steel heated and quenched |

| Roller material | First grade 45# steel, Hard Chrome Coated, heated and quenched |

| Forming Speed | 10-15 m/min |

| Drive Type | 1” Chain of transmission |

| Chain size | Japan CHOHO 100# |

| Machine Frame stand | Welded structural steel, thickness 12mm |

| 5.3 Hydraulic Stamping&Cutting Device |

| Cutting type | Hydraulic stop cutting |

| Hydraulic pump power | 5.5 KW |

| Hydraulic pressure | 12Mpa |

Hydraulic Blade &cutter material | Cr12, quenching process 58-62 |

| Cutting length tolerance | 10m±2mm |

| 5.4 Electrical System |

| PLC system | Japan Mitsubishi |

| Length Controller | Encoder Japan KOYO |

| Operation | China MCGS Touch Screen |

| Inverter | Japan YASKAWA |

| Voltage | 380V/50Hz/3P |

Roofing Sheet Roll Forming Machine Price

Roofing sheet roll forming machine price is based on drawing and customer’s budget. you can find used panel Roll Forming Machine in any place, but if you really want to use roof tile forming machine for a long time without any failure and maintenance. you can send your drawing of the roofing sheet profile and let our experienced engineer design metal roof making machine.

According to our domestic and oversea roof and wall panel.in fact, LOTOSFORMING establishes roofing machine manufacture and installs more than 50 different profile roof panel machine in own workshop. So any customer needs galvanizing and color-coated roof and wall panels, you may contact LOTOSFORMING. Metal roof tiles systems offer many benefits, including:

- Increased longevity

- Cost efficiency

- Higher quality material

- Extreme-weather performance

- Contemporary, sleek appearance

- Extensive warranties

- Environmentally friendly

FAQ:

1-How does the layer switching system work?

The machine uses a hydraulic switch to select either the top or bottom forming layer. The operator can switch profiles through the PLC control panel within seconds, ensuring continuous production without manual adjustments.

2- What is a Double Layer Roll Forming Machine?

A Double Layer Roll Forming Machine is a space-saving production line that can manufacture two different roof or wall panel profiles on a single frame. It allows easy switching between top and bottom layers, reducing cost and floor space while increasing efficiency.

3-How can I request a quotation for a Double Layer Forming Machine?

Send your profile drawings, material specifications, coil width, and desired production speed to LOTOSFORMING. Our engineers will provide a customized technical proposal and quotation within 24 hours.