Downspout Roll Forming Machine

Downspout Machine

- Home

- Downspout Machine

Downspout Roll Forming Machine

we are specialized manufacturers of Downspout Machine, Downspout Roll Forming Machine, Water Gutter Metal Sheet Forming Machine. automatic round water downpipe machine or water downspout roll forming machine are used to provide the water system for buildings. gutter downspouts are vertical pipes that are used to divert rainwater away from a building’s foundation.

LOTOSFORMING have the following styles of downspouts machines to choose from:

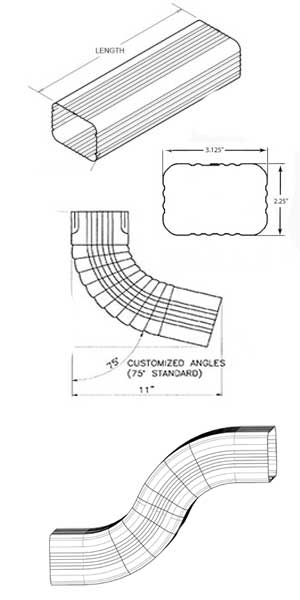

Rectangular Downspouts forming machine

Plain Round Downspouts forming machine

Round Corrugated Downspouts forming machine

- Spiral Downspouts forming machine

- Rainspout Roll Forming machine

- downspout pipe roll forming machine

Down pipe roll forming machine

in the same way, A downspout is a pipe that runs vertically along the side of the home. It is connected at the top to a hole in the gutter channel. The other end bends outward and usually sits several inches above the ground. This allows the water to flow away from the home as it exits the pipe. A gutter is a channel installed at or just below the roofline at the edges of the home where the roof slopes downward. It is usually made of vinyl or aluminum or copper also, stainless steel. around rain gutter has a slight downward pitch toward the corners of the home, encouraging rainwater or snowmelt to flow “downhill” through the gutters and into the downspouts.

Downpipe Machine design capacity

- Raw material thickness: Aluminum: 0.5mm

- Input width: 270mm

- Production line working speed: 0-6m/min

- Forming machine dimension: about L12,000*W1,000mm*H1,300mm

- Machine weight: about 7,000kgs

- Machine components

This Downspout Machine production line will be combined with a manual decoiler, feeding table, roll forming machine part, hydraulic cutting unit, output table, hydraulic oil pump, and electrical control cabinet, and so on.

Downpipe Machine design capacity

- Raw material thickness: Aluminum: 0.5mm

- Input width: 270mm

- Production line working speed: 0-6m/min

- Forming machine dimension: about L12,000*W1,000mm*H1,300mm

- Machine weight: about 7,000kgs

- Machine components

This Downspout Machine production line will be combined with a manual decoiler, feeding table, roll forming machine part, hydraulic cutting unit, output table, hydraulic oil pump, and electrical control cabinet, and so on.

| Roll Forming system: | ||

| Roller groups | 19 stations of forming roller | |

| Roller material | 45# Steel with heat treatment, HRC58-62°, Chrome coating | |

| Roller shaft dia. | Φ65mm | |

| Shaft material | 45# Steel | |

| Motor | 7.5KW | |

| Transmission way | Chain | |

| Machine frame body | Square tube welded frame | |

| Roller supporter | Wall structure | |

| Roller bearing | 6210 HRB | |

FAQ :

1-Does the machine include an elbow forming unit?

Yes. Many downspout roll forming lines include an automatic elbow forming machine, which creates bends or elbows for connecting downspouts to the gutter system.

2-Can the machine produce different downspout sizes?

Yes. By adjusting roller tooling, the machine can produce various diameters and sizes of downspouts to suit residential, commercial, or industrial needs.

3-Does the machine have punching and cutting functions?

Yes. It typically includes hydraulic punching systems for outlet holes and automatic cutting systems (hydraulic or flying cutters) to ensure precise lengths.

4-How is the quality of the finished downspouts ensured?

The machine is built with precision rollers, strong frames, and PLC controls, guaranteeing consistent thickness, smooth edges, and perfectly shaped pipes.