Drawer slides roll forming machine

- Home

- Drawer slides roll forming machine

Telescopic Channel Drawer Slide Roll Forming Machine

LOTOSFORMING is the professional automation solutions equipment manufacturer from China. We committed to three main kinds of ▷ Drawer slides roll forming machine | Telescopic Drawer Slide ◁ : Standard, Heavy duty, and multiple stands hole punch type to roll form various types of slide rail such as 2-fold ball bearing slide, full extension telescopic channel slides, drawer runner, steel ball slide, and hidden slides, etc. The roll forming equipment of drawer channel production lines is customized according to specific requirements. Our experienced engineers contribute passion in developing unsurpassed Drawer slides roll forming machine and roll forming techniques to satisfied customers from all over the world.

Drawer Slides Forming Machine

Telescopic Channel Roll Forming Machine Drawer slides can increase the functionality of cabinets in kitchens and other areas with lots of storage while making them considerably easier to use. A popular feature of some drawer slides is the ability to allow the drawer to slide closed quietly and with very little effort. To choose the right drawer slide for your application, you will need to know the drawer depth, mounting configuration and the amount of weight your drawers will have to hold. Drawer slides are generally distinguished by two characteristics: weight classification and specialty mounting designs.

Drawer Ball Bearing Slide Roll Forming Machine

Light-duty slides are designed to shoulder up to 75 lbs. Light-duty slides are most commonly used in domestic applications like kitchens where several drawers are placed in a cabinet.

Medium-duty slides have an average weight capacity of 120 lbs. Also common in domestic applications, medium-duty slides are used where heavier items like pots and pans need to be stored.

Heavy-duty slides hold between 100 and 500 lbs. and are intended for large storage purposes either in the kitchen, garage or office.

Soft Close Drawer Slide Roll Forming Machine

Soft-Close is easily the most popular type of drawer slide in the industry. Soft-closing drawer slides do an excellent job of protecting the drawer from damage commonly caused by closing it too fast. Using hydraulic dampeners, these types of slides not only increase the life of cabinets and furniture, but they also help reduce noise. These slides’ shock absorbing functionality make them the ideal choice for rooms like kitchens and offices. For more detailed information, check out this year’s best-selling soft close drawer slide.

Automatic Drawer Slides Assembly Machine Processes of drawer slides roll forming is a continuous cold rolled steel strip passing through a plurality set of upper and lower shaped rollers and then punching, embossing, straightening, and cut off to length. Straightening is an important part to avoid material twisting or curling. A roll forming line is often provided with a straightening mechanism to make sure the material is nicely formed in a predetermined shape to meet the original design.

DRAWER BALL SLIDER RAIL AUTOMATIC PRODUCTION LINE Technical Proposal

1) Forming Flow

Material Coi→ Decoiling→ Feeding→ Roll Forming→ Straightening →

Hydraulic/Mechanical Punching & Cutting-Off→ Finished Slide (one stroke

finished then for zinc painting separately)

2) Raw Material

(1) Material: Stainless Steel/Carbon Steel

(2) Material thickness: 1.0-1.2mm(maximum up to 1.5mm)

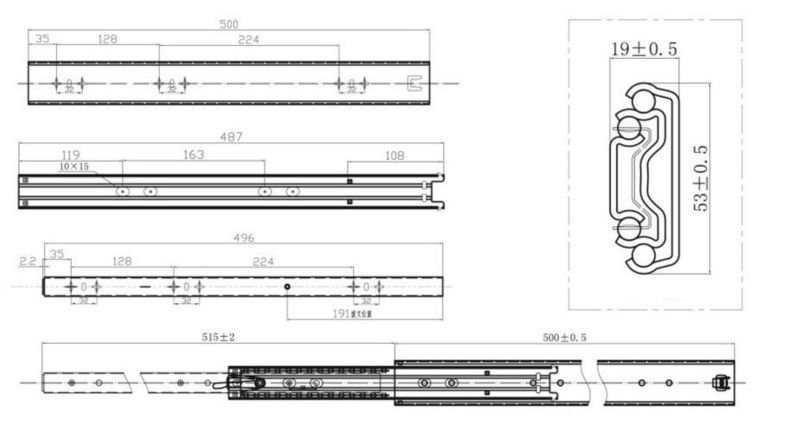

(3) Slider rail width: 35#/42#/45#(customer should choose one size)

(4) Slider length: 10’’,12’’,14’’,16’’,18’’,20’’

3) Forming Machine parameter

| No. | Item | Spec./Data |

| 1 | Roller Station | 16 groups |

| 2 | Roller Material | DC53 & Cr12MoV |

| 3 | Roller Station joint | Steel entire board |

| 4 | Roller Bracket | One side of the Bracket is integrated structure, Material A3, Thickness 38mm; Another side of the Bracket is independent supporter, Material QT40-17, could be disassembled separately. |

| 5 | Axis Dia. | 58mm |

| 6 | Main Axis material | Cr40, high-frequency treatment Hardness HRC55°-57° |

| 7 | Main Bearing | NSK 6309 |

| 8 | Punching & Cutting mode | Hydraulic/Mechanical |

| 9 | Productivity | 25-28pcs/min (16’’) |

| 10 | Drive Type | Gear with Gearbox and Worm |

| 11 | Machine frame | 100 x 100 square pipe welded with 35mm steel plate on surface |

4) Full Automatic Ball Assemble Machine

The line combined below machine unit:

1. Inner slider riveting machine

2. Assemble main machine

3. Slope conveyor

4. Flat conveyor

5. Outer slider end bender machine

6. Ball clamp manipulator

Working speed: about 32pcs/min