Fire Proof Window Frame Roll Forming Machine

- Home

- Fire Proof Window Frame Roll Forming Machine

Anti Fire Door Frame Making Machine

Wuxi LOTOS Manufacturing is one of the professional ▷ Fire Proof Window Frame Roll Forming Machine | LOTOS 2025 ◁ factory in China. If you have yourself door design, show us your design drawing, the good suggestion can be given out by our engineer. LOTOS offers you an outstanding quality range of Anti Fire Steel Door Frame Roll Forming Machine such as :

- Customized Fire Door Roll Forming Machine

- Anti-Theft Door Production line

- Fireproof Shutter Door Roll Forming Machine

Fire Doors Machine

- Fireproof Shutter Door Roll Forming Machine

fireproof door frame machine

- China Door Frame Making Machine

- fire door frames roll forming machine

- Anti-Theft Door Machinery

- Anti Fire Door Frame Roll Forming Machine

Window Screen Frame forming machine

These screen frame kits are constructed of roll-formed frame material and they come in a mill finished color.

screen frame Used when the screen is recessed into the opening. The lip then forms a seal around the opening. Flyscreen windows Frame is a roll-form framing, sometimes called Knife Edge or Lip frame.

Anti Fire Door Frame Making Machine

Fire Door Roll Forming Machine

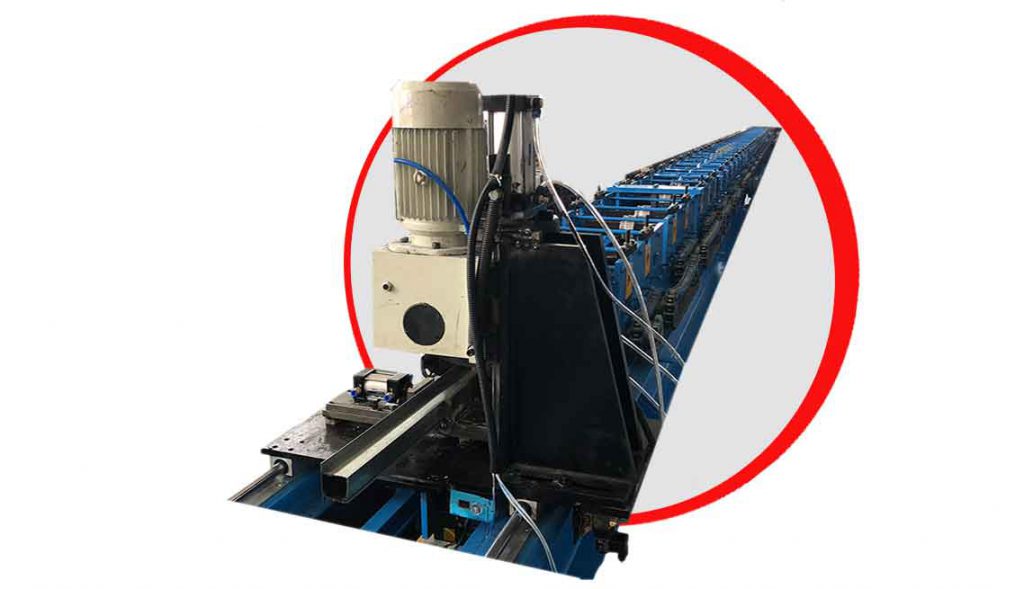

Fire Rated Window Frame Roll Forming Machine

Fire-resistant windows frame are given a fire-resistance rating and are usually made of steel. They are designed to be kept closed, and any gaps between the wall and the door must be filled with a fire-resistant sealant.

1) Production working flow

Manual decoiler→roll forming machine—> pneumatic tracking cutting saw→ automatic output table

2) Machine design capacity

- Raw material thickness: 1.0mm

- Input material width: 288mm

- Raw material yield limit: galvanized steel, and carbon steel

- working speed without punching: 10-20m/min

- Working area: about L25,000*W1,000mm*H1,200mm

- Machine G.W: 12,000KGS

3) Machine components

This Fire Rated Frame Roll Forming Machine production line will be combined with manual decoiler, and roll forming machine part, and automatic output table, and hydraulic pump station and electrical control cabinet, and so on.

Each part technical parameter

| Manual decoiler |

| Loading capacity | 5T |

| Steel coil I.D. | φ480-φ508mm |

| Steel coil O.D | max φ1000mm |

| Cantilever width | 400mm |

| Roll Forming Machine |

| Roller groups | 33 stations |

| Roller material | 45# steel with heat treatment, HRC58-62° |

| Roller shaft dia. | Φ75mm |

| Shaft material | 45# with quenching and tempering |

| Motor | 7.5KW*2sets |

| Transmission way | 1.25” Chain |

| Machine frame body | 350# H beam welded, Stress-Relieving |

| Roller supporter | Wall panel structure |

| Roller bearing | HRB, 30213 |

| Frequency inverter | DELTA |

| PLC | DELTA |

| Screen touch screen | DELTA |

| Encoder | Omron |

| Low voltage | Schneider |

| Cutting precision |

| Cutting length | ±0.5mm |

| Vertical Tolerance | ±0.5mm |

| Horizontal tolerance | ±0.5mm |

| Cutting way | Pneumatic tracking cutting saw |