Greenhouse Gutter Machine

- Home

- Greenhouse Gutter Machine

Slide 1

Slide 1

Slide 2

Slide 2

Slide 2

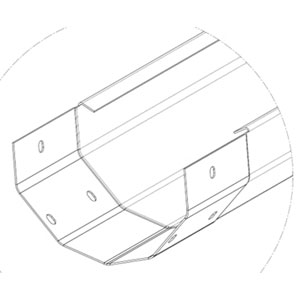

Greenhouse gutter roll forming machine

Actually, The Greenhouse Gutter Machine design to produce Gutters and a hanging system at the desired length in the greenhouse on-site. The seamless technology minimizes leaks and Ensures the manufacturer´s ease of operation and lower costs.

This type of machine can be called a portable gutter machine Because that is move by a diesel engine that is moved by chains with rubber protection and incorporates the online gutters manufacture system.

This assembly is designed for the maximum use of the water with nutrients, taking into account the large dimensions of the greenhouses, and facilitating the reuse of drainage water, with the consequent cost savings in both water and fertilizers.

Greenhouse Galvanized Steel Rain Gutter roll forming machine

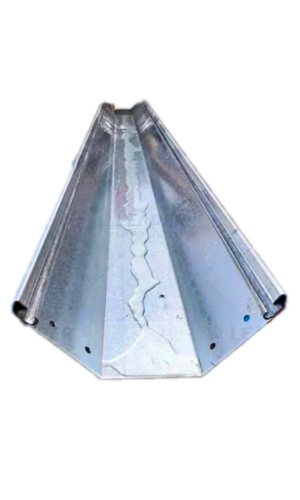

The Greenhouse Galvanized Steel Rain Gutter Roll Forming Machine is an advanced industrial tool designed to manufacture durable rain gutters from galvanized steel. It operates by feeding steel coils into a series of rollers that gradually shape the material into precise gutter profiles, tailored for greenhouse structures. The galvanized steel provides excellent corrosion resistance, ensuring the longevity of the gutters in harsh outdoor conditions. This machine offers high production efficiency, automation, and minimal material waste, making it ideal for large-scale production in agricultural and construction industries. Its robust design ensures consistent quality and reliable performance.

Greenhouse Rain gutter machine

In modern greenhouse management, having a reliable and efficient gutter system is crucial. Gutters not only protect the structure from water damage but also play a key role in irrigation by collecting rainwater that can be recycled for use within the greenhouse. A Greenhouse Gutter Machine ensures the seamless installation of these systems, which are essential for sustainable and cost-effective greenhouse operations. By reducing the risk of water-related issues, these machines contribute to the longevity and efficiency of the greenhouse environment.

How a Greenhouse Gutter Machine Works?

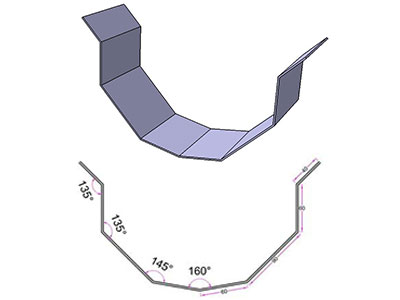

A Greenhouse Gutter Machine operates by feeding metal coils through a series of rollers and cutting mechanisms, forming them into custom designed gutters. These machines can be adjusted to create gutters of various sizes and shapes depending on the specific requirements of the greenhouse structure. The process is automated, allowing for high efficiency and accuracy, reducing the need for manual labor. With its ability to form seamless gutters, the machine ensures a perfect fit and minimizes potential leaks or breakdowns in the water management system.

Greenhouse Gutter Roll Forming Production Line

Using a Greenhouse Gutter Machine offers several benefits for greenhouse builders and operators. First, it significantly speeds up the construction process by automating the formation and installation of gutters. Second, it ensures consistent quality and precision, which are vital for maintaining a stable greenhouse environment. Additionally, these machines reduce waste by producing gutters that fit perfectly, thereby lowering material costs. Overall, a Greenhouse Gutter Machine is a vital tool in the construction of efficient, water conscious greenhouses, contributing to both sustainability and cost savings.

Greenhouse Gutter Machine

- Machine design capacity

- Raw material thickness: 0.6-0.8mm

- Input material width: 280mm(will be confirmed after the final drawing)

- Suitable raw material: Mg-Al, PPGI

- Production line working speed: 8-12m/min

- Working area: about L75,000*W850mm*H1,000mm

- Machine weight: about 6,000kgs

- Each part technical parameter

| |||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||

Don’t forget subscribe to our youtube channel

FAQ:

1-What is a Greenhouse Gutter Machine?

A Greenhouse Gutter Machine is a roll forming system designed to produce high-quality steel or aluminum gutters for greenhouse structures. It ensures precision, durability, and consistent profiles suitable for greenhouse water drainage and structural support.

2-Why are gutters important in greenhouse construction?

Gutters in greenhouses play a vital role in water collection, irrigation management, and structural strength. They help redirect rainwater, prevent waterlogging, and improve the efficiency of water use in agricultural applications.

3-What materials can a Greenhouse Gutter Machine process?

Most machines can process galvanized steel, pre-painted steel, aluminum, and stainless steel coils. The material choice depends on the durability, corrosion resistance, and budget requirements of the project.

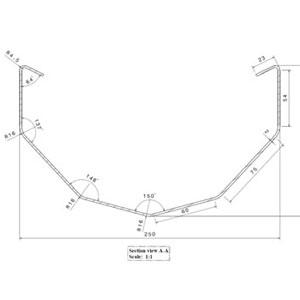

4-What profiles can be produced with a Greenhouse Gutter Machine?

A Greenhouse Gutter Machine can be customized to produce various gutter profiles, including U-shaped, semi-circular, and box-type gutters, depending on greenhouse design specifications.

5-How does LOTOSFORMING ensure the quality of gutter roll forming machines?

LOTOSFORMING provides advanced roll forming technology with robust machine frames, precision rollers, and automated control systems to guarantee consistent profiles, high output capacity, and long machine lifespan.