Gutter Roll Forming Machine

- Home

- Gutter Roll Forming Machine

Rain Gutter Forming Machine

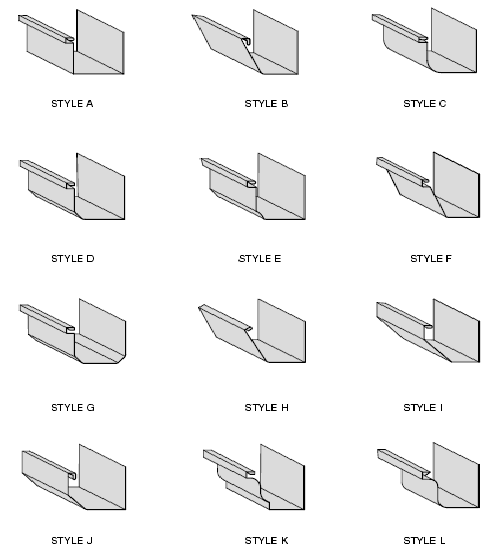

A rain gutter or surface water collection channel is a component of the water discharge system for a building. gutters and downspouts are an integral part of your home’s exterior. Gutters can also be made from galvanized steel and stainless steel. Installed and used properly, they direct and channel water away from the roof and home’s edge, preventing leaks. We have different types of Metal rain gutter roll forming Machines to fit into different requirements of each building such as :

K Style Gutters making machine

Fascia Gutters roll forming machine

Half Round Gutters production line

European Gutter forming machine

Rain gutter making machine

Gutter Guard roll forming machine

Gutter Cover A gutter cover is a protection system against leaves and other Residue. Without a cover, the stuff will slip into gutters and stack, causing your gutters to overflow. with a high-quality gutter cover you may never need to clean out gutters.

Perforated aluminum gutter guards are made from flat sheets of aluminum that are formed into shape by a roll forming machine. Most roll-formed aluminum gutter guards have a simple profile that is either has a smooth or wavy surface. A series of holes, slots, or louvers are perforated into the panels so water can flow through the cover openings into the gutter.

aluminum perforated gutter guard cover, used for Leaf and Debris Filter, the perforated gutter guard machine line has combined yangli crank press machine 16T, with perforation die.

k style gutter roll forming machine

The term K-style gutters refer to a view from the side of the gutter. Like other types of gutters, K-style gutters are available in different sizes.

There are many advantages for K-style gutter system including:

hold more water than a rounded gutter

Offers a stylish appearance

Strong and durable

easily found in many materials and sizes

less likely to bend or protrude when impacted by force

Gutter Forming Machine

Metal ▷ Gutter Roll Forming Machine | Gutters and Downspouts 2025 ◁ automatic working and controlled by Delta PLC control system, Our rich experience engineer can design and produce the K Style Gutters making machine according to your requirements, gutter samples, or drawings. Wuxi LOTOS is one of the professional rain gutter roll forming machine factories in Wuxi China. we can supply different kinds of roll forming machines for different types of rain gutter and a different sizes of Half Round Gutters also If you have yourself design, our engineer gives you a good suggestion.

What is a K-style gutter?

A gutter system is created of various parts, and every piece is crucial to it working properly.

Rain Gutter:

A rain gutter or surface water collection channel is a component of a water discharge system for a building.

Gutter Guards :

Solid guards, which cover all of the gutter except for a narrow crack to let the water through, do work well.

End Caps gutter:

A gutter end cap is the fitting that attaches to and closes off the end of the gutter.

Gutter downspout:

A downspout is a pipe that runs vertically along the side of the home. It is connected at the top to a hole in the gutter channel.

Gutter Offsets:

Offsets are used to curve the downspout around obstructions and obstacles.

gutter Elbows :

Elbows are made from your conductor pipe in aluminum, steel, or copper and there’s never damage to the protective coating.

Soffits and fascia :

Soffits and fascia are trim, flashing, or covers, for the eaves section of your roof.

1)Production working flow

Manual decoiler→Guide Feeding→roll forming machine→cut to the length →output table

2)Machine design capacity

- Raw material thickness: 0.6-0.8mm

- Input material width: 280mm(will be confirmed after the final drawing)

- Suitable raw material: Mg-Al, PPGI

- Production line working speed: 8-12m/min

- Working area: about L75,000*W850mm*H1,000mm

- Machine weight: about 6,000kgs

3)Machine components

This production line will be combined with a manual decoiler, feeding table, roll forming machine part, hydraulic cutting unit, output table, hydraulic oil pump, and electrical control cabinet, and so on.

Downpipe and Gutter Forming Machine

5)Each part technical parameter

| 1. Automatic hydraulic decoiler | ||

| 1.1 | Loading capacity | 3T |

| 1.2 | Steel coil I.D. | φ480-φ520mm |

| 1.3 | Steel coil O.D | max φ1800mm |

| 1.4 | Cantilever width | 400mm |

| 2. Roll Forming Machine | ||

| Roller groups | 18 stations | |

| Roller material | 45# Steel with heat treatment, HRC58-62° With 0.05mm Chrome coating | |

| Roller shaft dia. | Φ65mm | |

| Shaft material | 45# Steel | |

| Motor | 5.5KW | |

| Transmission way | Chain | |

| Machine frame body | 350H beam welded structure | |

| Roller supporter | Wall structure | |

| Roller bearing | HRB | |

| 3. Hydraulic cutting unit | ||

| Cutting way | Hydraulic Stop cutting | |

| Length measure | Japan Omron Encoder | |

| Cutting die | Cr12 with quenching treatment | |

| Die unit | Up 1 blade, down 2 blades | |

| 4. Hydraulic Pump Station | ||

| Motor power | 3KW | |

| Valve | HUADE | |

| 5. Electricity control cabinet | ||

| Frequency inverter | DELTA | |

| PLC | DELTA | |

| Screen touch screen | DELTA | |

| Low voltage | Schneider | |

Don’t forget subscribe to our youtube channel

FAQ :

1-What types of gutters can the machine produce?

The machine can be customized to produce various gutter styles such as K-style gutters, half-round gutters, box gutters, and square downspouts depending on project requirements.

2-What materials can be used in a gutter roll forming machine?

It can process galvanized steel, galvalume, pre-painted steel, aluminum, and copper, with thickness usually ranging from 0.3 mm – 1.2 mm.

3-What is the production speed of a gutter roll forming machine?

The average production speed ranges from 10–25 meters per minute, depending on the coil thickness, gutter profile, and machine automation level.

4-Can the machine produce different gutter sizes?

Yes. By changing the tooling and roller sets, the machine can manufacture different sizes and profiles of gutters to suit residential, commercial, and industrial applications.