High Speed Solar Strut Roll Forming Machine

- Home

- High Speed Solar Strut Roll Forming Machine

High Speed Solar Strut Roll Forming Technology

Nowadays, with the increasing importance of solar structures in renewable energy projects, the production of high quality structural profiles at high speed has become a fundamental industry requirement. The Lotos Solar Structural Profile Production Machine, equipped with advanced technologies and precise automation systems, is capable of delivering exceptionally high production speeds while maintaining dimensional accuracy and quality standards.

The high speed of the machine not only significantly reduces production time but also enables meeting the extensive demands of the market. Additionally, its advanced features including servo control systems, automatic punching, and precise cutting ensure that every produced piece reaches the end user with the highest quality and reliability.

This unique combination of speed, precision, and reliability makes our machine the ideal choice for solar structure manufacturers seeking to enhance productivity and reduce production costs.

Solar Strut Roll Forming Machine

This production line consists of a coordinated set of advanced equipment that fully covers the manufacturing process of solar structure profiles. The key stages include:

Hydraulic Decoiler with Loading Cart: For unwinding and feeding steel sheets into the production line.

Shearing and Butt-Welder: For initial sheet preparation through cutting and end welding.

Horizontal Accumulator: Provides temporary storage of sheets to optimize production flow.

Leveling on Bridge Unit: For flattening incoming sheets before forming.

Looper 1#: For precise sheet alignment prior to punching.

Isolated Punch Station with 8 Punch Seats: To create holes and custom shapes as per design requirements.

Looper 2#: Acts as an entry conveyor for continuing the process.

Roll Forming Machine Part: The main section responsible for the final shaping of profiles.

Flying Cutting Die: Enables precise, continuous cutting of profiles during production.

Output Conveyor: For transferring finished products smoothly.

Stacker: For collecting and organizing the produced profiles.

Electric Control Cabinet: Manages and controls the entire production line operations.

Solar Support Structures

The isolated punch frame with 8 punch stations allows precise and organized creation of holes and required shapes. Manual adjustment of each punch along the Y-axis provides greater flexibility in producing various profiles. The combination of these systems enables the machine to manufacture solar structural profiles quickly, accurately, and consistently, even in high volume production.

The roll forming machine, with its advanced design and precise control systems, is capable of producing structural profiles with high accuracy and consistent quality. Equipped with multiple rolling stations, it ensures precise and uniform shaping of profiles. The fully automatic width and height adjustment system, driven by a servo motor, allows fast and error free changes during production.

Additionally, the roll forming machine features a quick change tooling system, enabling rapid adjustments in profile thickness and type, providing high flexibility to meet diverse industrial requirements. This combination of capabilities makes the machine an ideal solution for manufacturing solar structural profiles and other industrial profiles in high volume production.

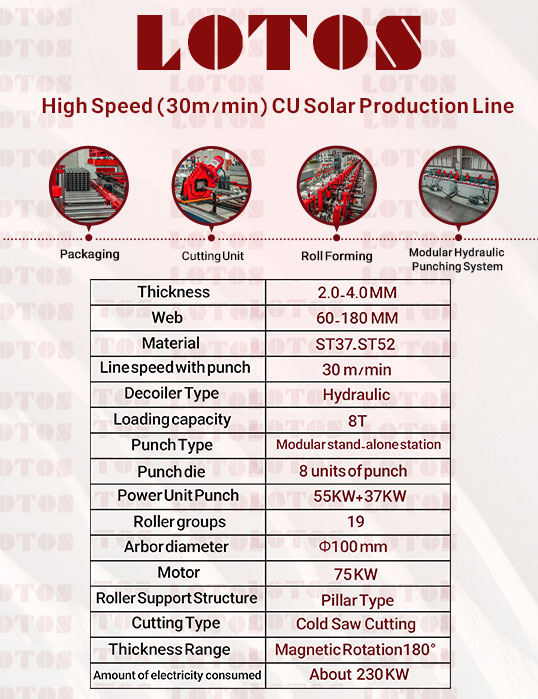

This production line, available in two different technical specifications, can be ordered from Lotos.

FAQ:

1-What is a High Speed Solar Strut Roll Forming Machine?

A High Speed Solar Strut Roll Forming Machine is an advanced roll forming line designed to manufacture solar strut channels with high precision, consistency, and production speed. It is widely used in solar mounting structures, photovoltaic supports, and industrial framing systems.

2-What are the main features of LOTOSFORMING’s Solar Strut Roll Forming Machine?

LOTOSFORMING machines are engineered for:

High-speed production up to 40–60 m/min

Automated punching and cutting systems

Flexible roll tooling for various strut sizes

Strong frame design for continuous operation

Easy integration with coil handling and stacking systems

3-Why choose a high speed model for solar strut production?

High-speed roll forming ensures maximum efficiency and reduces labor costs. It allows manufacturers to meet the growing demand for solar projects without compromising on quality or dimensional accuracy.

4-What materials can the Solar Strut Roll Forming Machine process?

The machine can handle galvanized steel, stainless steel, and pre-painted steel coils with different thicknesses, typically ranging from 1.5 mm to 3.0 mm, depending on customer requirements.

5-Can LOTOSFORMING customize the Solar Strut Roll Forming Machine?

Yes. LOTOSFORMING offers fully customized roll forming solutions, including punching patterns, strut sizes, line speed, automation level, and optional hydraulic or servo cutting systems.