Product description

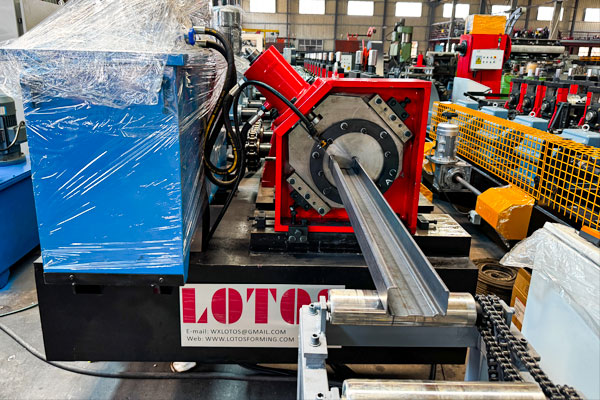

The C Type Box Beam Roll Forming Machine is an advanced production solution designed for manufacturing C shaped box beams with superior precision and efficiency. This roll forming machine transforms steel coils into high strength C type box profiles, commonly used in shelving systems, storage racks, and construction frameworks. With its automated roll forming process, the machine ensures consistent product quality, smooth edges, and accurate dimensions, making it ideal for mass production in industrial applications.

At LOTOSFORMING, we also provide specialized equipment such as the Horizontal Box Beam Roll Forming Machine and the Shelf C Purlin Roll Forming Machine, which are tailored for producing structural components used in shelving, racking, and building industries. These machines deliver high speed operation, low maintenance, and excellent durability, allowing manufacturers to meet the growing demand for robust and cost-effective structural profiles.

Ⅰ. Production working flow

Hydraulic Decoiler à Feeding Guide à Roll Forming Machine à Hydraulic Stop Cutting Die à Conveyor Wit Turning (Manual Over-Turning)à Clamping Machine àRun Out Table

Ⅴ. Each part technical parameter

| 1. Hydraulic Decoiler | ||

| 1.1 | Loading capacity | 5T |

| 1.2 | Steel coil I.D. | φ480-φ508mm |

| 1.3 | Steel coil O.D | max φ1500mm |

| 1.4 | Cantilever width | 600mm |

| 1.5 | Function | Motorized unwinding, hydraulic expansion |

| 2. Roll Forming Machine | ||

| 2.1 | Roller groups | 14 stations |

| 2.2 | Roller material | GCr15 with heat treatment, HRC58-62° |

| 2.3 | Roller shaft dia. | Φ75mm |

| 2.4 | Shalf material | 40Cr with quenching and tempering |

| 2.5 | Motor | 15KW |

| 2.6 | Width adjustment | Width 75-175mm, driven by servo motor |

| 2.7 | Transmission way | Gearbox |

| 2.8 | Machine frame body | Integrated welded plate housing frame |

| 2.9 | Roller supporter | Casting pillar stands |

| 3. Cutting Unit | ||

| 3.1 | Cutting method | Hydraulic stop cutting die |

| 3.2 | Cutting die | 7 units of cutter, T=1.4-2.0mm (spare cutter, 7 units, T-2.0-2.5mm) |

| 3.3 | Die material | CR12MOV |

| 4. Conveyor | ||

| 4.1 | Length | 4M |

| 4.2 | Function | Automatic over turning and clamping |