Shipping Container Making Machine

- Home

- Shipping Container Making Machine

SHIPPING CONTAINER ROLL FORMING MACHINE

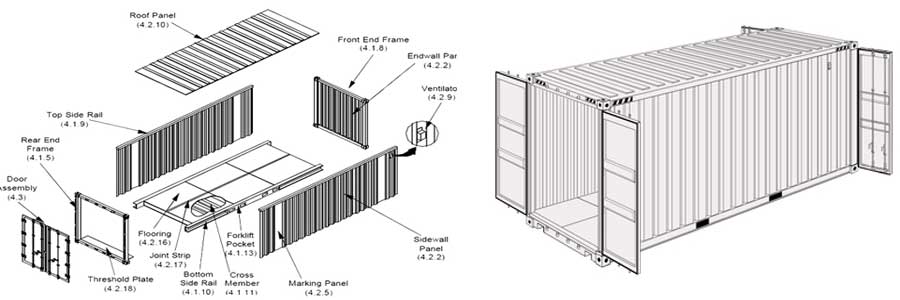

Shipping Container Making Machine: For producing Shipping containers panels wall panels are cut down from the large steel sheets into smaller sheets and a metal roll forming process use to create the wanted form.

The sheets are then waved and corrugated. The corrugation, which gives the walls their wave-like texture, adds strength to the container. Next, the smaller panels are laid out and welded together to create the full-sized wall panel. Finally, square tubing weld onto the top and bottom of the wall. This tubing allows the walls to weld to the floors and roof of the container.

- Summary

Material: Corten-A steel (SPA-H)

Material Thickness: 2.0mm

Size: 1024X2400(2700)mm

Main roll forming machine Power: 15KW*2pcs

Forming speed: 10-15m/min

- Main Parts of Shipping Container Making Machine

Hydraulic Decoiler

Feeding Guide

Roll Forming System

Hydraulic stop Cutting

Control system

- Working Flowing

Hydraulic decoiler , Roll Forming machine, hydraulic cutting unit, Output table

Container Side Panel Roll Forming Machine

- Roller groups 20 stations

- Material GCR15, with heat treatment, HRC58-62°

- Roller shaft dia. Φ110mm

- Shaft material 40CR with quenching and tempering

- Motor 15KW*2sets

- Transmission way Chain

- Machine frame body 500 H-beam

- Roller stand Wall panel

Hydraulic cutting unit

- Cutting way Hydraulic stop cutting

- Cutting die CR12MOV with quenching treatment

- Servo motor XINJE 5.5KW

Shipping Container Roof Panels Machine

LOTOS produce all kinds of structural steel containers parts machines such as shipping container man door kit, shipping container side panels, steel shipping container roof repair panels, shipping container door hinges, twist locks, or any other structural steel container part we can provide the high quality and best production line.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

1-What sizes of shipping containers can this machine produce?

LOTOSFORMING’s machines are designed to manufacture standard sizes such as 20ft, 40ft, and 45ft containers, as well as customized dimensions based on client requirements.

2-Is the machine suitable for both dry cargo and refrigerated containers?

Yes. The production line can be customized to produce both standard dry cargo containers and insulated or refrigerated containers, depending on the customer’s business needs.

3-What is the production capacity of a Shipping Container Making Machine?

Depending on the configuration, a full production line can manufacture 20–40 containers per day, ensuring high efficiency and consistent quality output.