Sigma Channel Roll Forming Machine

- Home

- Sigma Channel Roll Forming Machine

Our Products

Sigma Channel Roll Forming Machine

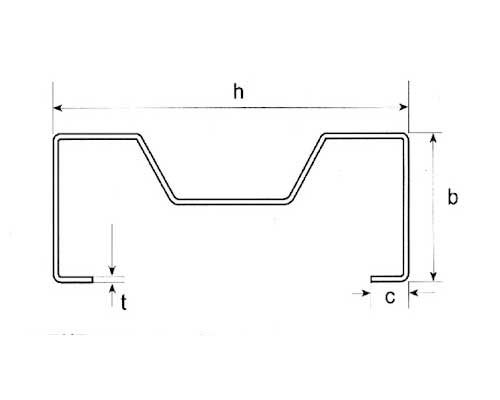

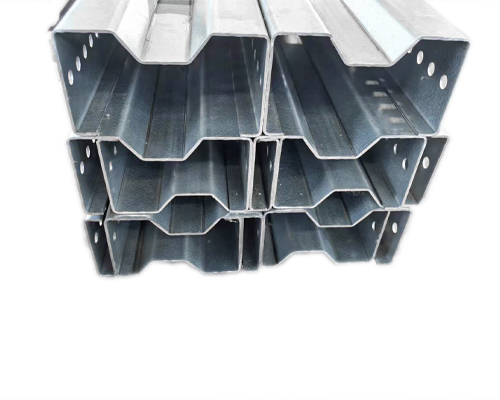

A Sigma Channel Roll Forming Machine is a specialized industrial system designed to produce high-precision sigma channels used in structural applications. These machines operate with advanced roll forming technology, ensuring consistent dimensions and superior strength in the finished profiles. Lotosforming, a leading manufacturer in China, provides efficient and durable solutions tailored to modern construction and industrial demands.

Applications of Sigma Channels in Industry

Sigma channels are widely used in construction, solar structures, warehouses, and heavy-duty frameworks. Their unique design provides enhanced load-bearing capacity, making them ideal for roofing supports, framing systems, and structural reinforcements. With the use of a sigma channel roll forming machine, companies can achieve high production efficiency while meeting strict industry standards.

Sigma Purlin Roll Forming Machine

The Sigma Purlin Roll Forming Machine is a specialized production system designed to manufacture high strength Sigma shaped purlins used in structural and solar applications. At Lotosforming, these machines are engineered for precision, efficiency, and durability, making them a reliable choice for manufacturers seeking advanced roll forming technology.

Technical Features of the Machine

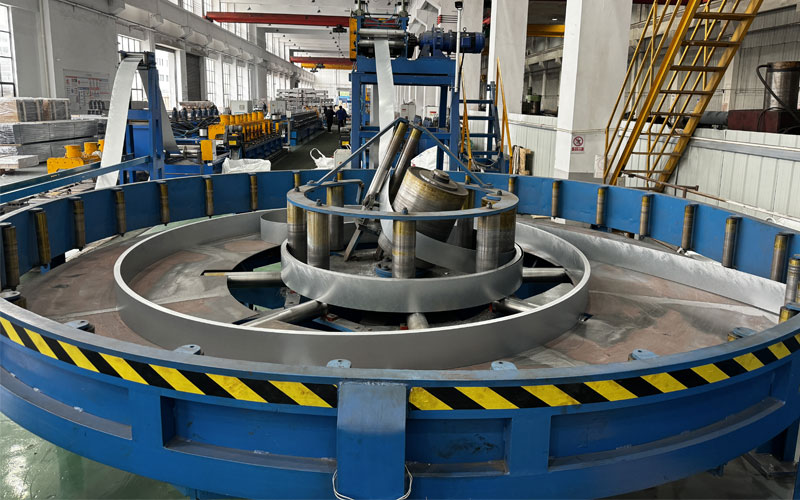

The Sigma Channel Roll Forming Machine incorporates precision rollers, automatic cutting units, and a programmable logic control (PLC) system for accuracy. It can process galvanized steel, cold-rolled steel, and other materials with different thicknesses. Lotosforming ensures that its machines are equipped with robust motors and hydraulic systems for long-lasting and reliable operation.

Advantages of Using Sigma Channel Roll Forming Machine

Investing in a sigma channel roll forming machine offers multiple benefits, including cost savings, increased productivity, and reduced material waste. The automation level minimizes manual intervention, ensuring uniformity across large production volumes. Lotosforming machines are designed for energy efficiency, making them a sustainable choice for modern manufacturers.

Role of Sigma Channels in Solar Structure Systems

In solar power projects, sigma channels are essential for mounting structures due to their durability and stability. The roll forming machine enables mass production of channels that meet the precision required for solar panel installations. Lotosforming provides machines optimized for producing solar structure components with high accuracy.

Customization Options Available

Every industry has unique requirements, and Lotosforming addresses this by offering customized machine designs. Options include adjustable roll tooling, variable width production, and integration with punching or embossing units. This flexibility allows clients to produce sigma channels tailored to their specific structural applications.

Quality Control in Sigma Channel Production

Maintaining product consistency is critical in the manufacturing of sigma channels. Lotosforming machines are engineered with advanced control systems that monitor dimensions, surface quality, and strength. This ensures that each sigma channel meets international standards and can withstand demanding applications.

Global Demand and Market Growth

The demand for sigma channels is growing globally, driven by construction expansion and renewable energy projects. Manufacturers who invest in reliable roll forming machines are positioned to capture a larger market share. Lotosforming supports businesses worldwide by supplying advanced sigma channel roll forming lines at competitive prices.

Why Choose Lotosforming for Sigma Channel Roll Forming Machine ?

Lotosforming stands out as a trusted name in roll forming technology, offering innovative, durable, and cost-effective machines. With years of expertise and a global customer base, the company ensures reliable after-sales support, training, and technical assistance. Choosing Lotosforming guarantees efficiency and quality in sigma channel production.

FAQ :

1. What is a Sigma Channel Roll Forming Machine?

A Sigma Channel Roll Forming Machine is an industrial machine designed to produce sigma-shaped steel channels with high precision. It uses a series of rollers to shape flat steel strips into continuous sigma channel profiles efficiently.

2. What are Sigma Channels used for?

Sigma channels are primarily used in construction, solar structure supports, warehouse frameworks, and industrial shelving. Their unique shape provides high load-bearing capacity and structural stability.

3. What materials can the machine process?

The machine can process a variety of metals, including galvanized steel, cold-rolled steel, and stainless steel, with varying thicknesses depending on the machine configuration.

4. What are the main components of the machine?

A Sigma Channel Roll Forming Machine typically includes a decoiler, roll forming unit, punching unit (optional), cutting unit, and a PLC control system for automated operation and precise control.

5. How is the machine controlled?

Most modern Sigma Channel Roll Forming Machines use a PLC (Programmable Logic Controller) system for easy operation. The control system manages speed, length, and punching operations, ensuring high accuracy and repeatability.

6. Can the machine produce different sizes of sigma channels?

Yes, the machine can be customized to produce sigma channels of various widths, heights, and thicknesses. Adjustments can be made by changing roll sets or modifying tooling.