Step Ladder Roll Forming Machine

- Home

- Step Ladder Roll Forming Machine

Step Ladder Making Machine

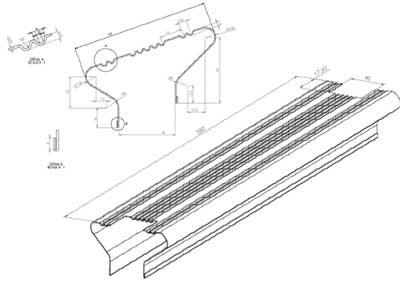

LOTOS can do a custom Steel Step Ladder Forming Machine. stairs roll forming machine and Stair Plate Roll Forming Machine is specially designed to produce Anti-slip home stairs and Step Ladder.

stair Plate Roll Forming Machine

The step ladder roll forming machine has an automatic servo motor continuous cutting system, the machine production speed can up to 15 m/min, it increases greatly the efficiency of the machine. A high-speed ladder roll forming machine is a cold roll forming machine that produces the ladder board. The step ladder is widely used in households, the advantages of the step ladder are light in weight and easy to carry.

Rolling Step Ladders Machine

1)Summary

- Material: Galvanized Coil, Steel

- Material Thickness: 0.6- 1.25 mm

- Main roll forming machine Power: 11KW

- Forming Speed: 12-5m/min

- Production line length: about 10m

2) Main Parts

- Manual Decoiler

- Feeding Guide

- Roll Forming System

- Hydraulic cutting

- Control system

- Output table

| Technical Parameter Stair Tread roll forming machine |

| Decoiler |

| Decoiler Type | Manual |

| Loading capacity | 3Ton Impassive to expanding |

| Roll Forming system with a feed panel unit |

| Axis Diameter | 60 mm |

| Forming Roller station | 20 groups |

| Main Axis material | First grade 45# steel heated and quenched |

| Roller material | GCR15, Hard Chrome Coated, heated and quenched |

| Pillar | Steel Pillar |

| Forming Speed | 12-5 m/min |

| Drive Type | 80# CHOHO CHAIN |

| Machine Frame stand | Integrated design new generation |

| Cutting Device |

| Cutting type | Hydraulic cutting |

| Cutting system power | 4 KW |

| Cutting length tolerance | ±0.5mm |

| Electrical System |

| PLC system | Delta |

| Length Controller | Delta |

| Operation | Delta Touch Screen |

| Inverter | Delta |

| Voltage | 380V/50Hz/3P |

| Run-out Table |

| Table quantity | 1 pcs*6m length |

| Structure | Angle bar welded |

FAQ :

1. What is a Step Ladder Roll Forming Machine?

A Step Ladder Roll Forming Machine is a specialized production line designed to manufacture high-strength step ladder profiles from galvanized steel or aluminum coils. It forms the ladder side rails or steps with precise dimensions and consistent quality for industrial and household ladders.

2. What materials can be used in a step ladder roll forming line?

The machine typically processes galvanized steel, stainless steel, or aluminum coils, depending on the ladder type and load requirements.

3. What is the production speed of a step ladder roll forming machine?

LOTOSFORMING’s step ladder roll forming machines offer adjustable speeds ranging from 10 to 25 meters per minute, depending on the profile complexity and material thickness.

4. Can the machine produce different step ladder sizes?

Yes. The line can be customized to produce various step widths, heights, and side rail designs using interchangeable rollers or automatic width adjustment systems.