API Tube Mill Line

- Home

- API Tube Mill Line

Our Products

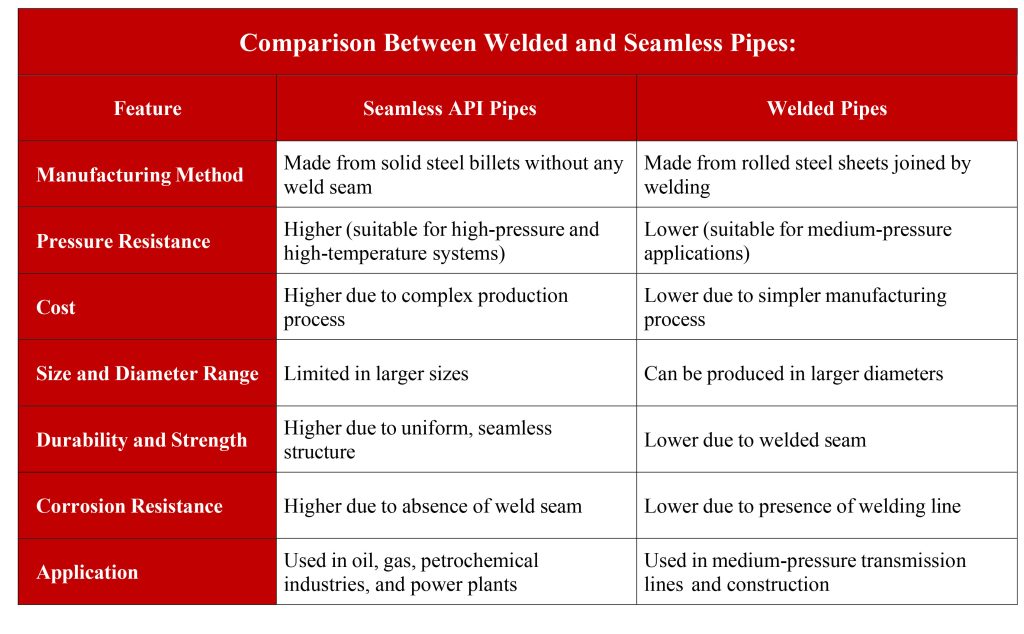

API pipes are generally categorized into two main types based on their manufacturing process:

- Welded Pipes:

• ERW (Electric Resistance Welded):

These pipes are made from rolled steel sheets, with the edges welded together using electric resistance. They are typically produced up to 24 inches in diameter and are suitable for medium-pressure transmission lines.

- LSAW (Longitudinal Submerged Arc Welded):

In this method, steel plates are welded longitudinally. These pipes are ideal for large diameters and are used in high-pressure transmission applications. - SSAW (Spiral Submerged Arc Welded):

Steel plates are spirally formed and welded in this process. SSAW pipes are generally produced in large diameters and are used for special applications in transmission lines.

- Seamless Pipes (Mannesmann):

These pipes are manufactured from solid steel billets without any welding seams. Thanks to their uniform structure, they are highly suitable for high-pressure and high temperature environments.

What is an API Tube Mill?

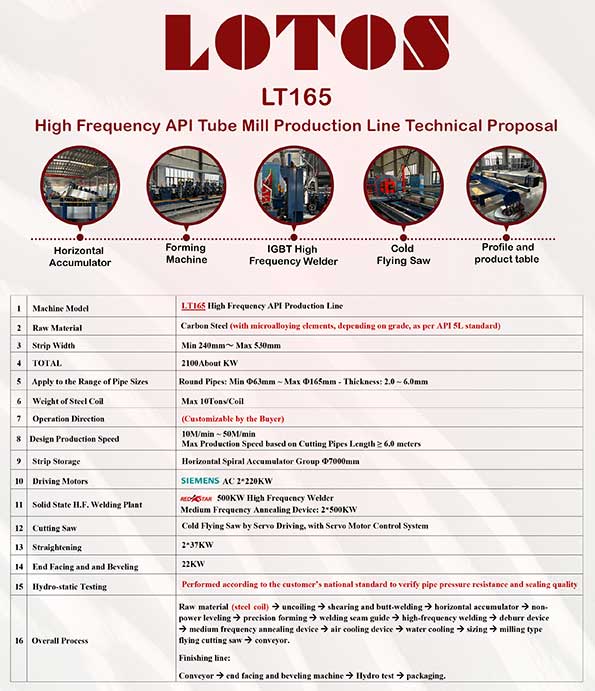

The API pipe production line is recognized as one of the most advanced and efficient systems in the oil and gas industry. This line is capable of producing both welded and seamless pipes that comply with internationally accepted API standards. Given the critical role these pipes play in transporting fluids and gases, their quality and durability are of utmost importance.

The use of cutting-edge technologies in welding, cooling, and quality control processes has enabled this production line to achieve the highest levels of productivity and safety. Key operations such as high-frequency welding, medium frequency annealing, and online quality testing are fully automated to ensure pipes with excellent mechanical and chemical properties.

Thanks to its ability to rapidly adjust pipe sizes and support a wide range of API grades, this production line offers high flexibility in meeting various market demands. Considering the strict standards applied in API pipe manufacturing, choosing this production line is a reliable solution for supplying high-quality pipes that withstand high pressure and temperature.

Main Components of the API Pipe Production Line:

- Uncoiling

- Shovel Feeding & Leveling

- Shearing and Butt-Welding

- Horizontal Accumulator

- Non-Power Leveling

- Rough Forming

- Precision Forming

- Welding Seam Guide

- Extrusion

- High-Frequency Welding

- Deburr Device

- Medium Frequency Annealing Device

- Air Cooling Device

- Water Cooling

- Sizing

- Milling Type Flying Cutting Saw

- Conveyor

Finishing Line:

1. Conveyor

2. Straightening

3. End Facing and Beveling Machine

4. Hydro Test

5. Packaging

For more information and expert consultation on selecting the best API pipe production line, feel free to contact our team.

Types of API Standards Related to Seamless Pipes:

• API 5L – For oil and gas transmission pipelines

• API 5CT – For casing and tubing in oil and gas wells

• API 5DP – For drill pipes

Comprehensive Review of the Hydrotest Process and Standards in Pipe Production Lines:

Hydrotest, or hydrostatic pressure testing, is a method used to assess the strength and leakage of pipes, tanks, and metal profiles. In this method, water or another fluid is introduced into the pipe or tank at a specified pressure to determine whether it can withstand the desired pressure without leaking.

Why is this test important?

Hydrotesting is a reliable and standard method for verifying the safety and quality of pipes, profiles, and pressure vessels. This test increases the service life of equipment, reduces the risks associated with leakage, and ensures safety across various industries.

- Because if pipes or tanks have leaks, they can cause hazardous accidents.

- Because this test is performed before installation and commissioning to prevent future damages.

- Because in industries such as oil and gas, water and wastewater, construction, and petrochemicals, pipes must withstand high pressures.

Step by step Hydrotest Procedure:

- Preparation and Cleaning:

The inside of the pipe is thoroughly cleaned to ensure that debris does not affect the test results. - Filling the Pipe with Test Fluid:

Usually water or an anti-corrosion solution is used.

All air bubbles must be completely removed since air can cause measurement errors. - Applying Pressure by Pump:

The fluid pressure is increased to a specified level (usually 1.5 times the working pressure of the pipe).

This pressure is held steady for a specified duration. - Leakage and Pressure Drop Inspection:If the pressure drops, it likely indicates a leak in the pipe.Leaks can be detected visually, by pressure sensors, or with thermal cameras.

- Draining the Fluid and Drying the Pipe: Water is drained, and compressed air is used to dry the pipe to prevent rust formation.

Important International Hydrotest Standards:

- API 1104: Testing and inspection of oil and gas pipelines

- ASME BPVC Section VIII: Design and testing standards for pressure vessels

- ISO 13703: Hydrostatic testing of pipelines in oil and gas industries

- EN 13445: Standards for unfired pressure vessels (Europe)

- ASME B31.3: Process piping and pressure testing standard

- NACE MR0175 / ISO 15156: Standards for corrosion resistance of equipment and pipelines

- ISO 9001: Quality management standard for testing and inspection

Equipment and Components Used in Hydrotesting

The equipment and parts used vary depending on the type of test (manual, semi-automatic, or fully automatic). Below are the main equipment, spare parts, and types of devices commonly used.

1. Main Hydrotest Equipment:

- High Pressure Pump:

Function: Generate the required pressure to inject water into the pipe or tank.

Types: - Manual: For low-pressure and small-scale tests

- Electric: For high-pressure tests (up to 2500 bar)

- Pneumatic (air-powered): For higher precision and better pressure control

- Water Reservoir:Function: Supply clean, corrosion-resistant, and co ntaminant-free water or testing fluid.

- High-Pressure Hoses & Fittings:

Function: Transfer high-pressure water from the pump to the pipe.

Types: Stainless steel, brass, or durable plastic. - Pressure Gauges and Monitoring Sensors:

Function: Measure and control pressure inside the pipe.

Types: - Analog: Simple and inexpensive, less accurate

- Digital: High accuracy, computer-connectable

- Relief and Drain Valves: Function: Prevent overpressure and enable water drainage after the test.

- 2. Spare Parts and Accessories

Water filters: Prevent suspended particles from entering pumps and pipes. - Special pump oils: Reduce wear in hydraulic pumps.

- O-rings and rubber packings: Prevent leakage at connections.

- High-pressure nozzles: For better injection of test fluid inside pipes.

- Temperature and humidity sensors: To monitor environmental conditions during the test.

Hydrotesting is one of the most important quality control stages in the production of pipes and pressure equipment. By following international standards and using appropriate equipment, it can ensure the safety, durability, and optimal performance of the equipment.

FAQ

1- How is the welding process performed in this line? High-frequency (HF) straight seam welding is used in this production line. A seam guide and extrusion unit are positioned before the welding stage, while a deburring unit and a medium-frequency annealing unit follow the welding process to ensure high weld quality and structural integrity.

2- Does this line offer a high level of automation? Yes, from coil butt-welding to the final cold flying saw cutting, all sections of the line are fully automated and precisely controlled.

3- How is the cooling process of the pipes performed? The cooling process consists of two stages: air cooling followed by water cooling. This dual system ensures the preservation of mechanical properties and helps control pipe warping.

4- What is the role of the annealing device in this line? Medium-frequency annealing is used to relieve internal stresses generated during welding. It enhances the flexibility and final strength of the pipe, especially for API-grade specifications.

5- What quality control systems are available in this production line? Weld seam guide, extrusion unit, leakage testing system, diameter and thickness measurement, precision cutting system, and optionally, online eddy current testing (ECT) can be included.

6- How are the pipes packaged at the end of the line? Pipes are typically bundled and strapped either manually or using an automatic stacking and strapping system.