Ceiling Channel Roll Forming Machine

- Home

- Ceiling Channel Roll Forming Machine

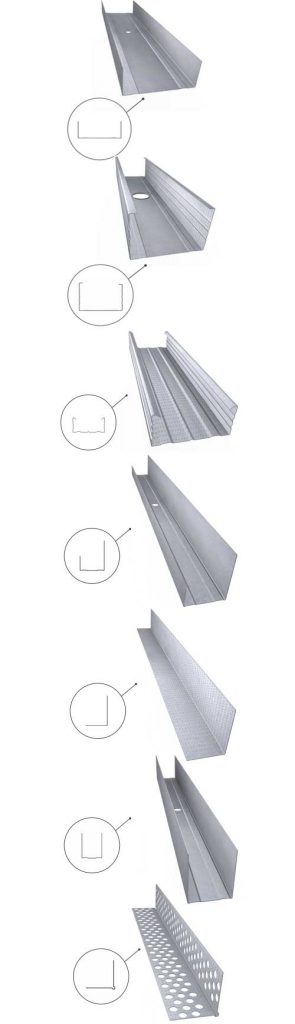

POP Channel Roll Forming Machine

LOTOS makes the best suspended ceilings machines. Suspended metal ceilings are technical profiles that make a system. the profiles must fit together perfectly during assembly to form a solid structure and once fixed they must be aesthetically impeccable. LOTOSFORMING hot sale automatic t bar / t-grid ceiling channel roll forming machine. LOTOS Roll forming machines for ▷ Ceiling Channel Roll Forming Machine | Furring Channel | Top Hat ◁ produce Impeccable profiles and connectors. There are a variety of false ceiling types that can be produced by LOTOS roll forming machine :

- pop channel machine

- lip channel roll forming machine

- Gypsum False Ceilings roll forming machine

- Metal Ceiling Tiles roll forming machine

- c channel roll forming machine

- furring channel roll forming machine

- top hat roll forming machine

- Suspended metal ceilings

- Partition wall structure

- principal profile

- Vertical stud

- Horizontal channel

Ceiling Roll Forming Machine

Hat Furring Channels Roll Forming Machine

Knauf Hat Furring Channels, Galvanized lightweight steel sections use as furring channel for drywall ceiling. . Drywall furring channel commonly clips with metal furring channel clips to the underside of the U-Channel. LOTOS Company sells any type Hat Furring Channels roll forming machine and wants to make sure your job is done right the first time; that’s why it’s so important that we talk before you purchase anything. These consultations are part of our service and are offered at no cost to you.

Folded Edge Ceiling Channels machine

Gypsum Ceiling Channel forming machine offered by LOTOS the most affordable rates and high in demand, different patterns.LOTOS can produce a Bulldog ceiling channel that uses for alongside the Bulldog Edge Channel and Bulldog Primary Channel. Folded Edge Ceiling Channels use for securing wall studs at floor and ceiling connection. Folded Edge channels are the most commonly called, FEC channels, gypframe ceiling channels, and MF Ceiling channels.

Ceiling T Bar Roll Forming Machine

Ceiling tee bars is also called ceiling grids or tee grids. The Gypsum T-Bar Ceiling is a low-cost, easy-to-install, and modified ceiling tile system. A variety of styles and patterns are available.

The Gypsum T-Bar Ceiling is designed so that each structure can be attached to each other without knotting or screwing in.

The minor grid system is simply attached to the main grid and the gypsum board is then attached to the T-bar. This provides easy installation with the ability to attach and detach tiles as required using the T-bar’s instant lock feature.

The T-Bar Ceiling provides a heat block feature and the tiles are also easy to remove in case the ceiling tiles’ system needs repair or replacing.

LOTOSFORMING hot sale automatic t bar / t-grid ceiling roll forming machine.LOTOS Roll forming machines for T-bars produce Impeccable profiles and connectors.

J channel machine

These j channel pieces use as trim and locking in the soffit panel. J-channel hides the cut lines of panels giving your project a clean finished look.

Siding trim is used to cover exposed panels and weatherproof corners and around doors and walkways, among other applications. J Channel roll forming Machines are equipped with a rigid steel frame and chrome-plated forming rolls for accurate and professional J channels.

Drywall Roll Forming Machine

Drywall is a panel made of gypsum, with or without additives, typically extruded between thick sheets of facer and backer paper, used in the construction of interior walls and ceilings. light gauge steel is a modern building material that comes in large panels having a gypsum core sandwiched between two heavy paper faces.

Steel Stud & Track construction became prevalent as a saving alternative to traditional lath and plaster. U channel Metal Profile offers a sturdy framework for the gypsum board to be fixed. This is a quicker method of installation. you can choose to use drywall metal profiles in vertical wall partitions and wall linings or in horizontal ceiling applications.

Roll forming machines for plasterboard profiles

Drywall Steel Sections or plasterboard profiles Limited has one of the most comprehensive ranges of cold-rolled products and systems for partitions, ceilings, wall linings, and light gauge structural steel framing. LOTOS supplies complete roll forming machines for drywall and ceiling constructions such as :

- Ceiling Drywall Profile roll forming machines

- Wall Angle Drywall Profiles roll forming machines

- Ceiling Perimeter Drywall Profile roll forming machines

- Top hat roll forming machine

- plasterboard ceiling profile machine

- Lip channel roll forming machine

- U channel roll forming machine

- Suspended metal ceilings forming machine

- Horizontal channel making machine

V keel suspended profile roll forming machine

The V Shape Ceiling Light Steel Keel Suspended is a kind of ceiling steel framing made by galvanized light steel. The quality and dimension of the product are past the international standard. It has a good look and is easy to install, also has a good market in the decoration industry. The ceiling suspends a system made of galvanized and painting boards of better anticorrosive and fire-proofing. V channel is made by good quality materials and professional work teams.

Angle Roll Forming Machine

The final product of an angle roll forming machine is a new building material, Wall angle light keels are one of the keels used in ceiling participation. The slotted angle roll forming machine creates to make those L profile wall angles in batch for huge production. It can make the corner looks smoother and speed up the construction period.

Metal suspended ceiling panel machine

If you are looking for a metal suspended ceiling panel machine, you have come to the right place. Metal Ceiling Tiles are clipped into a concealed tee bar grid system and are pushed from below the ceiling.

A wide range of metal ceiling tile hydraulic press machine options are available.

The produce of metal ceiling tile panels includes several steps. The production starts from the coil material, where the hydraulic decoiler in uncoiling the coil. In the hydraulic press machine, the edges of the metal drop tiles are bent and the ready products are stacked.

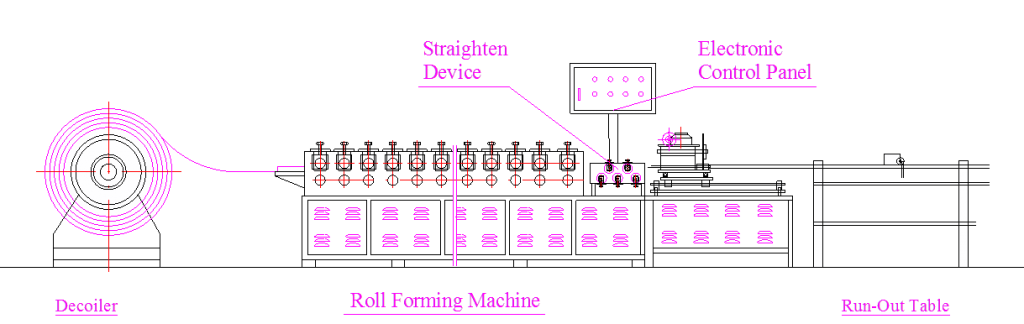

Machine specification :

Drywall roll forming machine

1) 3T manual decoiier

2) 9 stations of rollers, shaft φ65mm;

3) Roller material: GCR15, shaft material: 45# steel

4) Main motor: 5,5KW, K-series motor

5) Machine drive way: chain,Japan CHOHO

6) Roller supporter: wall panel

7) Bearing: Japan SKF

8) Cutting way: hydraulic servo tracking way,servo motor/2KW

9) Hydrualic pump motor: 3kw, larger cylinder

10) Line speed ≥35m/min

11) Program system: DELTA

12) Special request: LOGO press

Furring channel roll forming machine

1) 3T manual decoiier

2) 14 stations of rollers, shaft φ65mm;

3) Roller material: GCR15, shaft material: 45# steel

4) Main motor: 5,5KW, K-series motor

5) Machine drive way: chain,Japan CHOHO

6) Roller supporter: wall panel

7) Bearing: Japan SKF

8) Cutting way: hydraulic servo tracking way,servo motor/2KW

9) Hydrualic pump motor: 3kw, larger cylinder

10) Line speed ≥35m/min

11) Program system: DELTA

12) Special request: LOGO press & embossing roller

T-BAR ROLL FORMING MACHINE

1)Summary Partition

- Material: Galvanized Coil, colored steel

- Material Thickness: 0.5-0.2mm

- Main roll forming machine Power: 7.5 KW

- Forming Speed: 20-15m/min

- Dimension: 8×0.7×0.8 m (L*W*H)

2) Main Parts drywall metal stud and ceiling profiles machine

- Manual 3T un coil (2 pcs)

- Feeding Guide

- Roll Forming System

- Punch system

- Hydraulic Cutting

- Control system

- Output table

3) Working Flowing

Manual Un coiler—>Feeding —> Roll Forming —>punching —> &Cutting —>Output table

4) Working Flowing

| 5.1 Un coiler |

| Un coiler Type | Manual |

| Loading capacity | 3Ton Impassive to expanding |

| Roll Forming system with feed panel unit |

| Axis Diameter | 50 mm |

| Forming Roller station | 16 Groups |

| Main Axis material | First grade 45# steel heated and quenched |

| Roller material | First grade 45# steel, Hard Chrome Coated, heated and quenched |

| Forming Speed | 20-15 m/min |

| Drive Type | 1.25” Chain of transmission |

| Chain size | Japan CHOHO 100# |

| Machine Frame stand | Welded structural steel |

| Hydraulic Cutting Device |

| Cutting type | Servo tracking cutting |

| Cutting system power | 2.2KW |

| Cutting length tolerance | ±0.5mm |

| Hydraulic punching and clips Device |

| punching type | Saw Servo punching |

| Cutting length tolerance | ±0.5mm |

| Mechanism | Hydraulic |

| Molds | Hard Chrome Coated, heated and quenched |

| Clips punch mechanism | Hydraulic or mechanical |

| Clips molds | Hard Chrome Coated, heated and quenched |

| Electrical System |

| PLC system | PANASONIC or DELTA |

| Length Controller | Encoder KOYO |

| Operation | Touch Screen |

| Inverter | YASKAWA |

| Voltage | 380V/50Hz/3P |

FAQ :

1-What materials can be used in a ceiling channel roll forming machine?

It can process galvanized steel, pre-painted steel, and aluminum, with thickness ranging from 0.3 mm – 1.2 mm depending on project requirements.

2-What is the production speed of a ceiling channel roll forming machine?

The average speed is 10–25 meters per minute, depending on the channel design, coil thickness, and level of automation.

3-Can the machine produce different channel sizes?

Yes. With customized roller tooling, the machine can manufacture various ceiling channel sizes according to international standards (such as ASTM, BS, or local building codes).

4-Does the machine include punching and cutting units?

Yes. Most machines are equipped with hydraulic punching units for slots or holes and automatic cutting systems (flying or stop-to-cut) for precise length cutting without damaging the profil