Maintenance of solar PV systems

In solar structure manufacturing, precision and efficiency are critical to delivering high quality components for large scale projects. Modern roll forming lines integrate multiple processes decoiling, punching, roll forming, and cutting to streamline production and ensure consistent results. LOTOSForming specializes in designing and supplying advanced equipment that brings these processes together for maximum productivity.

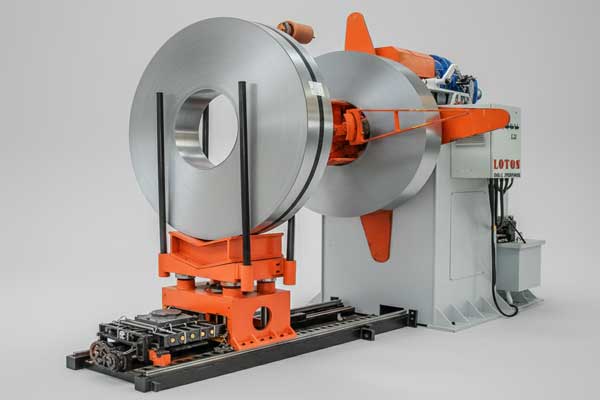

Decoiler

The decoiler is the starting point of any roll forming line. It unwinds metal coils and feeds them smoothly into the production system. A high quality decoiler ensures steady material flow, reducing tension and preventing damage to the coil. LOTOSForming’s decoilers are designed to handle various coil weights and widths for solar structure manufacturing.

Punching

After decoiling, the material passes through the punching section. Here, holes and slots are precisely created to match design specifications for solar structures, such as mounting brackets and channels. Automated punching units increase accuracy, reduce manual labor, and improve overall production speed.

Roll Forming

Roll forming is the heart of the production line. This process gradually shapes the flat strip into the desired profile (C, Z, U, or custom solar channels) using a series of rollers. LOTOSForming’s roll forming machines are engineered for high precision and repeatability, ensuring every solar structural component meets international quality standards.

Cutting

Once the profiles are formed, the cutting unit ensures each piece is cut to the exact length required for assembly. Advanced cutting systems minimize burrs, reduce waste, and deliver ready-to-use components for solar mounting systems.

Integrated Solutions by LOTOSForming

By combining decoiler, punching, roll forming, and cutting into a single automated line, LOTOSForming provides manufacturers with a seamless, efficient, and cost-effective production process. This integration improves output, reduces downtime, and guarantees the durability and quality of solar structure components.

FAQ :

1-What is device maintenance of a solar structure line?

Device maintenance of a solar structure line involves routine inspection, servicing, and calibration of equipment such as decoilers, punching units, roll formers, and cutting machines to ensure optimal performance and product quality.

2-Why is regular maintenance important for solar structure lines?

Regular maintenance prevents unexpected breakdowns, extends the lifespan of equipment, maintains production efficiency, and ensures consistent quality of solar structure components.

3-Which parts of a solar structure line require the most maintenance?

Key areas include rollers, cutting blades, punching tools, electrical systems, and lubrication points, as these components directly impact accuracy and productivity.

4-How often should maintenance be performed on a solar structure line?

Preventive maintenance should be scheduled regularly based on usage levels, typically including daily checks, monthly inspections, and annual overhauls to ensure continuous operation.

5-Does LOTOSForming provide support for maintenance of its equipment?

Yes, LOTOSForming offers full training, technical support, and after-sales services to help clients perform proper maintenance and maximize the efficiency of their solar structure lines.