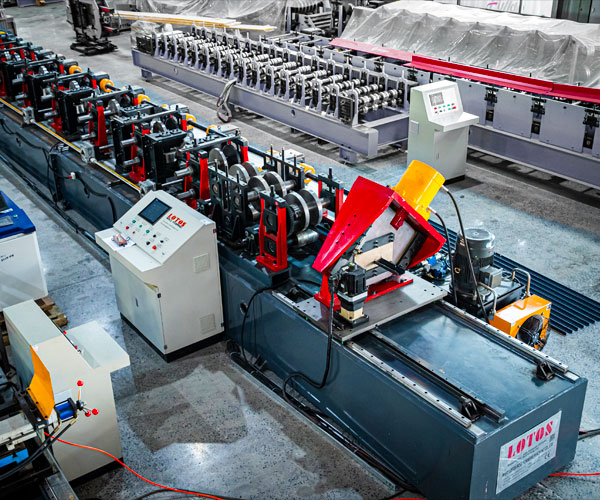

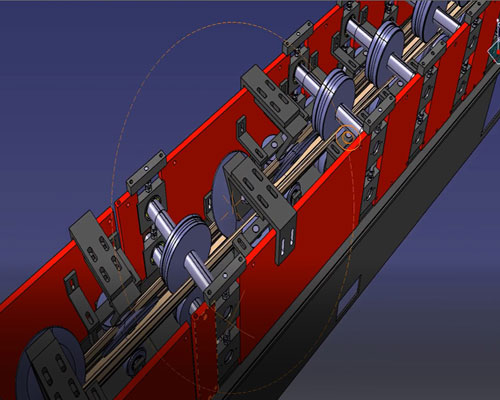

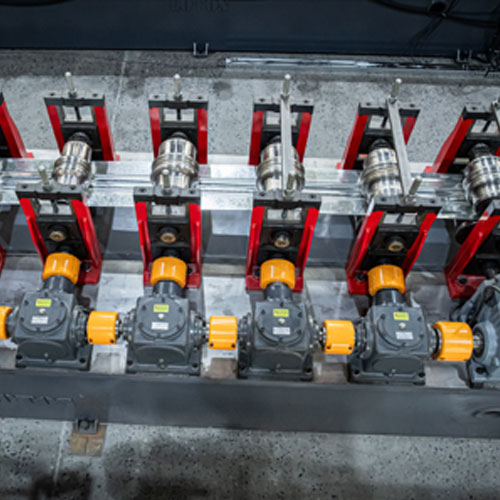

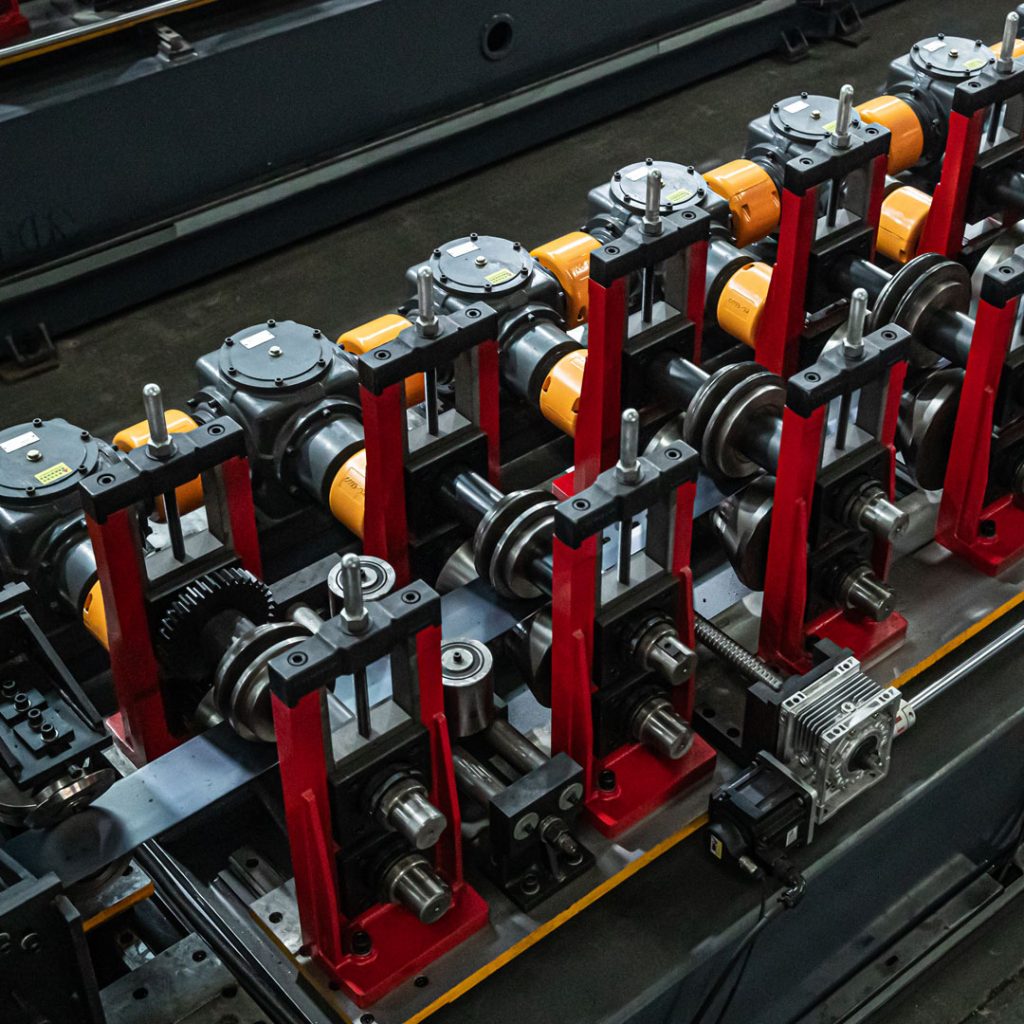

Sheet Metal Roll Forming Machines Metal roll forming systems are essential in the modern manufacturing industry, offering continuous bending of metal sheets into desired cross-sections. These systems are highly automated, cost efficient, and capable of producing complex profiles with exceptional …

Read More

Roll Forming Application

Global Leader in Solar Channel Roll Forming

Global Solar Panel Frame Forming Machine LotosForming has established itself as the global leader in solar channel roll forming, providing innovative and efficient machinery to meet the growing demand of the solar energy sector. With over a decade of specialized …

Read More

Best Cold Rolled Steel Manufacturer in China

China Cold Rolled Steel Manufacturers Cold rolled steel plays a crucial role in modern manufacturing due to its superior strength, precision, and surface finish. As one of the leading cold rolled steel manufacturers in China, LotosForming delivers high quality steel …

Read More

Unistrut Channel Roll Forming Manufacturer in China

Unistrut Channel Roll Forming Machine Unistrut channels are essential components in the construction and electrical industries, widely used for supporting wiring, piping, and mechanical systems. As a leading Roll Forming Machine Manufacturer in China, LOTOSFORMING is dedicated to producing state …

Read More

Top 10 Tube Mill Manufacturers in the World

Tube Mill Working Principle Several international manufacturers have set high standards in tube mill innovation.These companies are known for their durable machinery, precision forming systems, and advanced control technologies.Among them, LotosForming distinguishes itself by offering high quality, cost effective solutions …

Read More

Leading Company in the Solar Structure Production Line

Solar Structure Manufacturing As the global shift toward renewable energy accelerates, the demand for reliable and durable solar mounting structures has increased significantly. These structures are critical for ensuring the stability and performance of solar panels under various environmental conditions. …

Read More

Best Tube Mill Manufacturer in Asia

Top Steel Tube Manufacturing Company Asia is home to some of the world’s most competitive and technologically advanced manufacturers in the steel pipe and tube production industry.With a growing demand for infrastructure, automotive, and construction applications, the region has become …

Read More

Top 10 Chinese Manufacturers of Roll Forming Line

LOTOSFORMING guides and explains many of the common issues encountered in the roll forming process and roll forming operation manual, all factors that contribute to possible problems such as material, design, and manufacture.

Read More

Top Cold Rolled Manufacturing Companies

LOTOSFORMING guides and explains many of the common issues encountered in the roll forming process and roll forming operation manual, all factors that contribute to possible problems such as material, design, and manufacture.

Read More

Best companies producing roll forming machines for solar structure

De-Coiler offered by us finds application as an accessory machine that is used as support for expanded metal mesh machine.

Read More