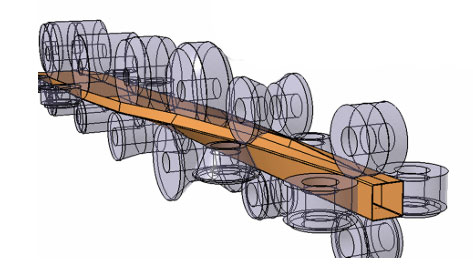

Direct Square Tube Mill Line

Automatic Size Change, Direct Square Welded Pipe Line. This production line is equipped with high-frequency welding equipment for producing square rectangular and irregular pipes. The raw material used in this production line is strip steel after longitudinal cutting.

The strip steel passes through an uncoiler, straightening, leveling, and shear welding machine before entering the looper storage device. It is formed and bent to the required shape and size, then welded, deburred, cooled, sized, and cut into the required size pipe by a flying saw. It is then transported to the packaging rack through a roller conveyor for packaging and becoming a finished product.