High speed Automatic CU Channel Roll Forming Machine

- Home

- High speed Automatic CU Channel Roll Forming Machine

Slide 1

Slide 2

strut channel machine

In the modern roll forming industry, efficiency and precision are critical factors for success. The Automatic CU Channel production line, featuring a high speed capacity of 30m/min with multiple punching capabilities, is an advanced solution that meets industrial demands. This system is widely used in construction, infrastructure, and framing applications due to its speed, precision, and automation.

How Do Automatic CU Steel Channel Machines

The Automatic CU Channel Roll Forming Machine is designed to optimize production while maintaining high quality standards. Some of its key features include:

- High Speed Production: The machine operates at 30 meters per minute, significantly increasing manufacturing efficiency.

- Multiple Punching Stations: Equipped with an advanced hydraulic punching system, it ensures accurate hole placements without interrupting the production process.

- Precision Roll Forming: Utilizes high-quality rollers and guides for consistent CU channel dimensions.

- Fully Automated System: Features a PLC control system for seamless operation and reduced manual intervention.

- Customizable Designs: Supports various CU channel specifications to meet different project requirements.

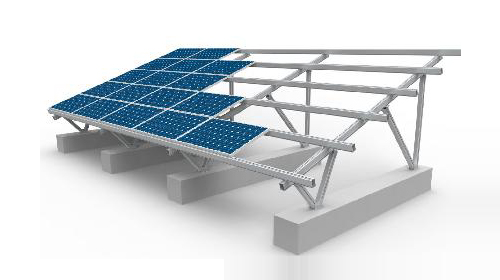

solar panel bracing

Investing in a high speed CU channel roll forming machine provides multiple benefits, including:

- Enhanced Productivity: The ability to produce at 30m/min allows manufacturers to fulfill large orders quickly.

- Cost Effective Manufacturing: Reduces labor costs due to automation while increasing output efficiency.

- High Precision & Consistency: Ensures uniformity in CU channel dimensions, leading to better structural integrity in applications.

- Versatile Application: Suitable for drywall framing, ceiling systems, and lightweight steel construction.

The multiple punching system integrated into the CU channel machine enhances its adaptability across different projects. This feature enables:

- Custom Punching Patterns: Accommodates various hole designs for electrical, mechanical, and fastening applications.

- Hydraulic or Servo Punching: Ensures clean and precise holes with minimal material distortion.

- Synchronization with Forming Process: Reduces production time by combining punching and roll forming in a single operation.

Multi Head Punching Machine

LOTOSFORMING is a leading manufacturer of roll forming machines, offering high performance CU channel production lines tailored to industry needs. Our machines stand out due to:

- Innovative Technology: We integrate advanced automation and high speed capabilities for optimal production.

- Custom Engineering Solutions: We design machines based on specific client requirements.

- Reliable After-Sales Support: We provide comprehensive technical assistance and training.

FAQ :

1-Can the CU Channel Roll Forming Machine be customized?

Yes. LOTOSFORMING provides customized solutions, including punching patterns, profile sizes, line speed, automation level, and optional hydraulic or servo cutting systems.

2-Why is high speed automation important for CU channel production?

High-speed automatic systems reduce labor costs, improve production efficiency, and ensure consistent quality, allowing manufacturers to meet large-scale construction demands quickly.

3-How does LOTOSFORMING ensure machine quality?

LOTOSFORMING uses advanced CNC machining for rollers, strict quality inspections, and real production testing before shipment to guarantee accuracy, durability, and reliability.

4-What industries use CU Channel Roll Forming Machines?

They are primarily used in construction, drywall partition systems, ceiling framing, light steel building structures, and cable management systems.

5-Why choose LOTOSFORMING as your CU Channel Roll Forming Machine supplier?

LOTOSFORMING, established in 2014, is a leading Chinese manufacturer of roll forming machines with expertise in CU/U channel lines, solar structures, tube mills, slitting, and heavy-duty roll forming solutions. The company offers global service and cost-effective equipment.