Product description

Key Features:

Material Thickness: up to 4 mm

Production Speed: 15 m/min

Profiles: Adjustable CU purlins

Hydraulic Punching & Cutting: smooth and accurate processing

PLC Automation: ensures stable operation and high productivity

This machine is widely used in warehouses, factories, and solar mounting structures, offering manufacturers a reliable and efficient solution for purlin production.

Technical Proposal:

Ⅴ. Each part technical parameter

| 1. Hydraulic Decoiler+Loading Cart | ||

| 1.1 | Loading capacity | 7T |

| 1.2 | Steel coil I.D. | φ480-φ508mm |

| 1.3 | Steel coil O.D | Max φ1800mm |

| 1.4 | Cantilever arm length | 600 mm |

| 1.5 | Function | Motorized unwinding, hydraulic expansion |

| 1.6 | Remark | Coupled with loading cart Coupled with disc brake Coupled with pneumatic press arm |

3. Isolated Punch Station | ||

| 3.1 | Feeding guide | Adjustable at same side |

| 3.2 | Leveling unit | 2-roller feeding, 5-roller leveling |

| 3.3 | Servo feeding | Driven by servo motor 5.5KW |

| 3.4 | Punch die | 6 units of punch seat with dies |

| 3.5 | Structure | Isolated punch frame for dies |

| 3.6 | Die material | CR12MOV |

| 3.7 | Remark | Whole surface is well milled |

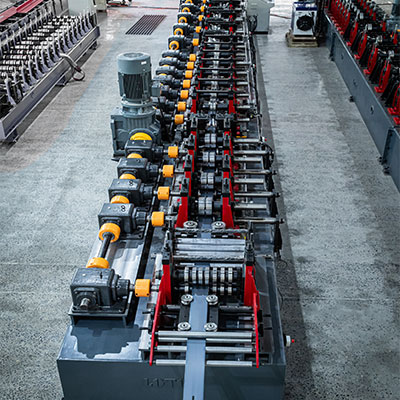

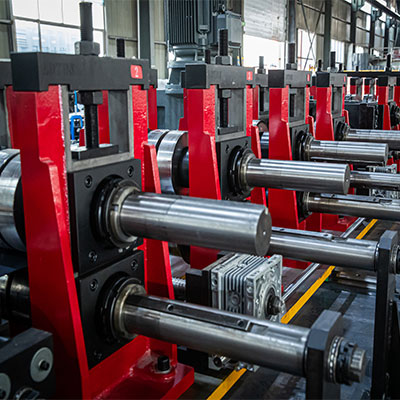

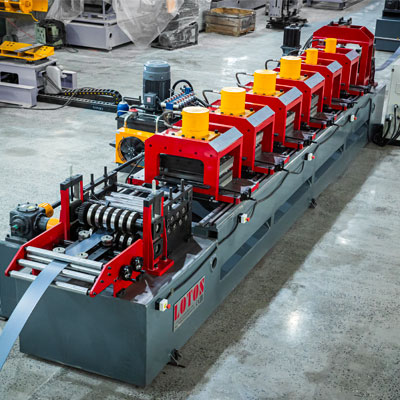

4. Roll Forming Machine | ||

| 4.1 | Roller groups | 18 + 6 stations |

| 4.2 | Roller material | CR12 with heat treatment, HRC58-62° |

| 4.3 | Arbor diameter | Φ 85_95 mm |

| 4.4 | Arbor material | 40Cr with quenching and tempering |

| 4.5 | Motor | 22 KW *2 , Siemens BEIDE |

| 4.6 | Width/height adjustment | Driven by servo motor, DELTA 2.2KW |

| 4.7 | Transmission way | Gearbox transmission |

4.8 | Machine frame body | Integrated welded plate housing frame, surface well milled |

| 4.9 | Roller supporter | Casting pillar stands |

| 4.10 | Thickness change | Manual Interchange tooling system |

| 5.Cutting Unit

| ||

| 5.1 | Cutting method | Servo tracking cutting die, non stop

|

| 5.2 | Cutting die | 4 dies (size could be customized)

|

| 5.3 | Die material | CR12MOV |