What’s affects on roll forming machine price?

we wanna explain to you the most common question that all staff – are they sending an email and asking from us “why you’re forming machine price is so much different?!” and how many options you have that affect your forming machine price. so we start with the heavy-duty machine, that we already installed rollers here as you can see we are from Wuxi manufacturing for roll forming machine.

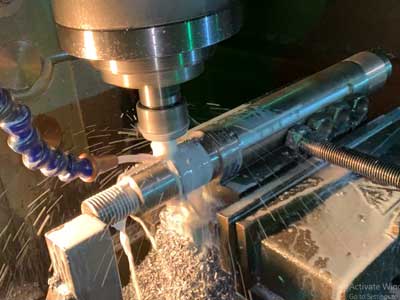

so we start from here for the parts that we use for this machine as the CIE standard for line term usage and heavy-duty performing. for bearing, we use original SKF from Germany. chain connection between the gears uses a heavy-duty good brand for chain connection for garden connection because some of the factory you can see they don’t use garden they just connected the gears with the shaft directly by some coupling but we use a garden for heavy-duty.

This machine will be using for guardrail the thickness up to four millimeters. we’re showing you the different price of the machine which part affects. firstly they start from the basement structure. the surface is 20 points or 25 millimeters thickness. the body is 10 millimeters thickness inside has a connection between the left and right. it makes it heavy duty machines.

Roll Forming price

just now for difference, you check this machine a pillar, the gears, the garden, the SKF bearing, chain; everything her going to assemble to make a finished roll forming machine is a heavy-duty and high-quality machine.

sometimes as you know some of the customers need a better price based on their profile thickness so we can also design them. LOTOS makes sure what they design and what they afford customer it will work well and satisfy our demands.

so now maybe you realize by the price of roll forming machines the same profile to different customers different suppliers. it has a different offer and a different price. parts if using SKF bearing or using other bands, gears or change, what kind of pillars you use, what kind of structure.if you have any questions inquiry feel free to send us by email.