Product description

Key Features:

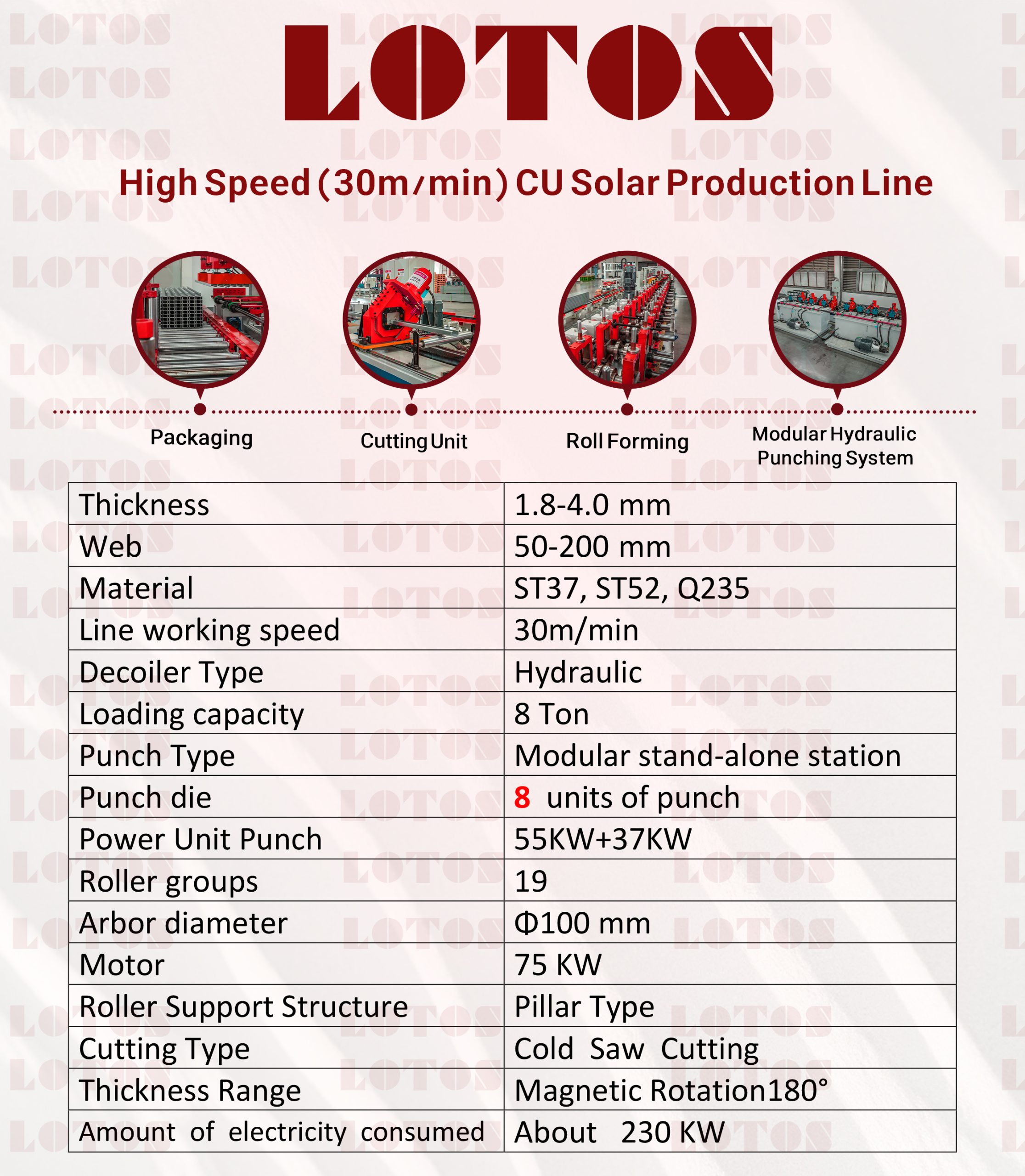

Heavy Duty Punching Unit: Mortise & tenon punch frame with 8 punching stations, made of CR12MOV steel with precision machining for superior durability.

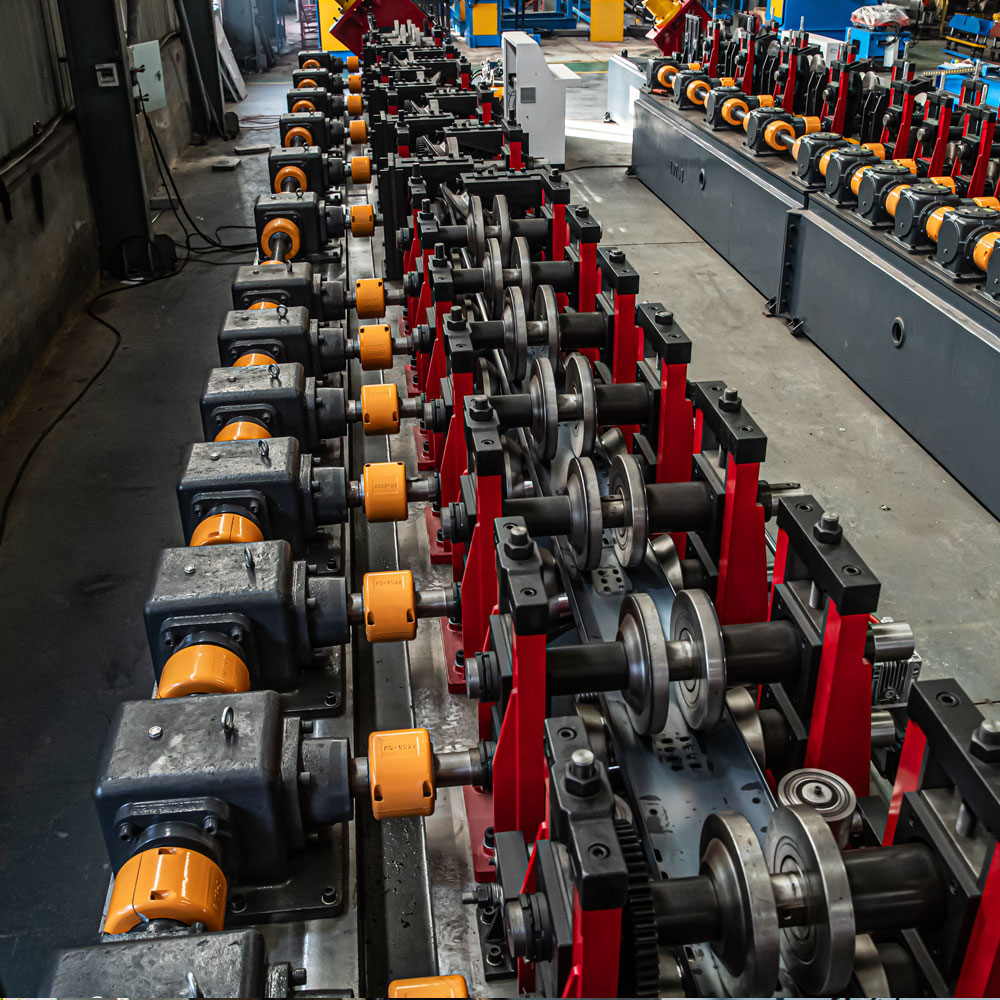

Roll Forming Stations: 19 stations for C-purlins (90°) and 22 stations for angular purlins, equipped with hardened CR12MOV rollers (HRC 58–62°) ensuring consistent accuracy.Powerful Transmission: 75KW Siemens motor, spiral bevel gearbox, and integrated welded frame for maximum strength and stability.Non Stop Flying Cut System: Servo tracking cutting die with 2 interchangeable molds for flexible size adjustment.

Automated Stacking & Handling: Motorized conveyor with overturning system and magnetic claw, ensuring precise positioning and stacking of finished purlins.This production line is the ideal choice for manufacturers seeking fast, accurate, and cost-efficient production of C and U purlins for industrial and solar energy projects.

FAQ:

1. What materials can this C/U Purlin Roll Forming Machine process?

This machine is designed for cold-rolled galvanized steel, hot-rolled steel, and

other structural-grade materials with maximum thickness up to 4 mm, ensuring

durability and strength for industrial and solar projects.

2. What is the lifespan of the rollers and cutting dies?

Rollers are made of heat-treated CR12MOV (HRC 58–62°) with long service life

under heavy-duty use. Cutting dies are also CR12MOV and can be re-sharpened or

replaced depending on production volume.

3. Is after-sales service and training provided?

Yes. LOTOS provides global installation, operator training, and technical support,

as well as spare parts supply for long-term reliability.

Reviews

There are no reviews yet.