Product description

PU Foam Rolling Shutter Door Roll Forming Machine

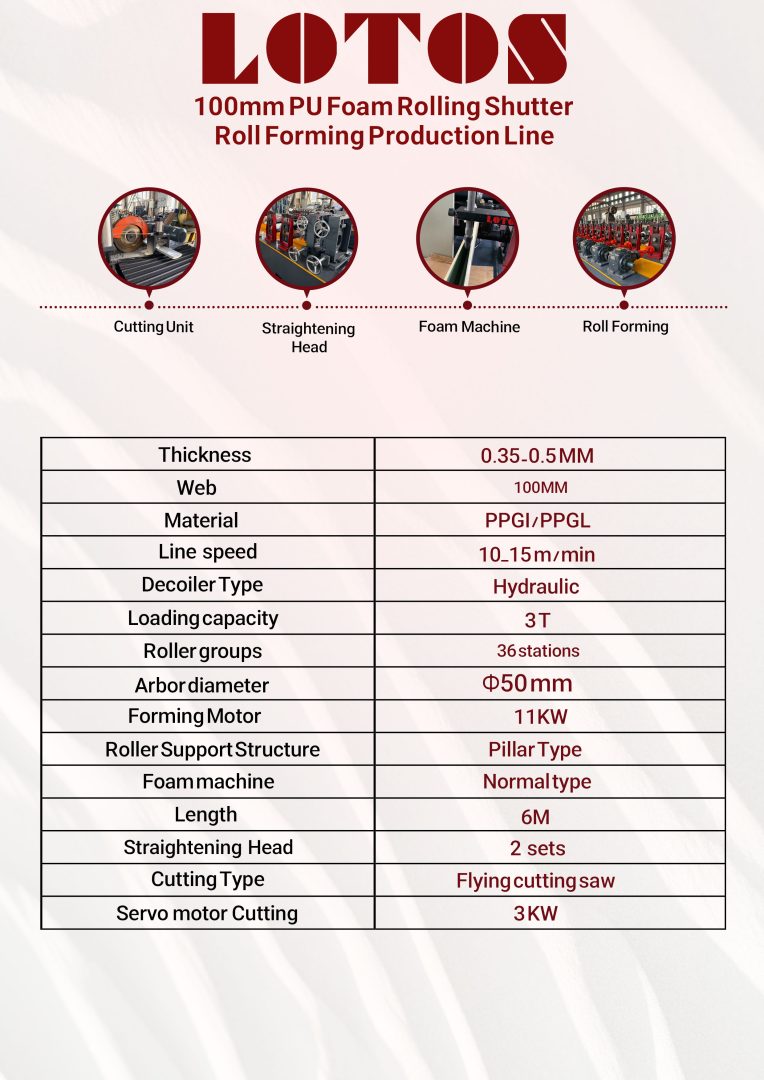

The PU Foam Rolling Shutter Door Roll Forming Machine 100MM is a high performance production solution designed for manufacturing insulated rolling shutter door profiles with superior strength, thermal insulation, and noise reduction. Engineered for precision and durability, this machine is ideal for industrial, commercial, and residential shutter door applications.

This roll forming line is capable of processing steel or galvanized coils into 100 mm PU foam filled shutter slats, ensuring consistent profile dimensions and smooth surface quality. The integrated polyurethane foam injection system provides excellent insulation performance while increasing structural rigidity of the shutter profile.

With a stable line speed of 10–15 meters per minute, the machine offers a balance between productivity and forming accuracy, making it suitable for medium to high volume production environments. Advanced forming rollers, manufactured from hardened alloy steel, guarantee long service life and minimal maintenance.

Working Flow :

Un motorized Decoiler → Roll Forming Machine → Foam Machine (6M heating chamber) →Foam Gun → Forming Machine →Straightening Head Flying Cutting Saw → Run out table

FAQ:

The machine is suitable for processing galvanized steel, pre-painted steel, and color coated steel coils, ensuring high quality surface finish and long-term corrosion resistance.

PU foam rolling shutter doors are widely used in warehouses, factories, commercial buildings, parking facilities, and residential properties due to their insulation and security benefits.

PU foam-filled profiles provide thermal insulation, sound reduction, improved rigidity, and energy efficiency, making them ideal for industrial, commercial, and residential rolling shutter door applications.

Yes, the machine includes an integrated PU foam injection and curing system, synchronized with the roll forming process to ensure uniform foam distribution inside the shutter profiles.