Product description

CU Solar Mounting Channel Roll Forming Machine

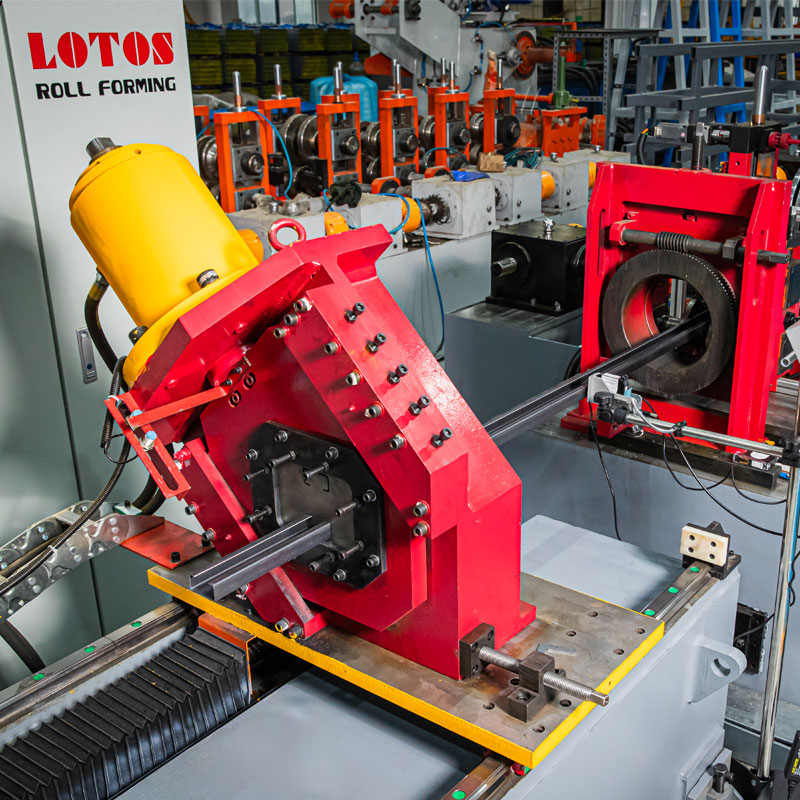

The CU Solar Mounting Channel Roll Forming Machine 2.5MM – 25 m/min by LOTOS Forming is a high precision and efficient production solution designed specifically for manufacturing C and U solar mounting channels used in photovoltaic support systems. This machine is engineered to deliver stable performance, accurate forming, and consistent quality for medium to high volume solar structure production.

The roll forming line is capable of processing steel thicknesses from 1.0 mm to 2.5 mm and supports a wide range of materials, including S235–S550, galvanized steel, cold rolled steel, and Zn-Al-Mg coated steel, ensuring excellent strength and corrosion resistance for outdoor solar installations. With a maximum line speed of 25 meters per minute, the machine achieves an optimal balance between productivity and forming accuracy.

Equipped with a robust roll forming structure and precision-machined rollers, the machine ensures excellent profile straightness, dimensional consistency, and smooth surface finish. The production line can be integrated with servo feeding, punching systems, and servo tracking flying cut-off, enabling accurate hole positioning and precise length control to meet strict solar project requirements.

The machine features a PLC controlled automation system with touch screen HMI, allowing operators to easily monitor production parameters, adjust profile sizes, and switch between different channel specifications efficiently. Its modular design allows customization according to customer drawings, hole patterns, and stacking requirements.

Working Process

10 ton Hydraulic Automatic Decoiler with Coil Car → Shearing & Butt Welding Machine → Four-Roll Feeding Device → 160 Ton Punch Press → Servo Feeding & Leveling Machine → Main Roll Forming Machine → Inkjet Marking Machine → Servo Tracking Hydraulic Flying Cut → Intelligent Discharging System → Automatic Stacking System

- Technical Specifications

- 10-Ton Hydraulic Decoiler with Coil Car

- Max. loading capacity: 10 tons

- Coil ID: Φ508–Φ610 mm

- Coil OD: Φ1300–Φ2200 mm

- Cantilever length: 600 mm

- Functions:

- Electric decoiling

- Hydraulic expansion

- Double-layer expanding blades

- Motor power:

- Main motor: 7.5 kW

- Hydraulic station motor: 4 kW (Siemens Bede)

Structure & Features:

- With coil car

- Disc brake system

- Recoiling function

- Pit sensor

- Pressing arm

2.Shearing & Butt Welding Machine

Equipment Parameters

- Model: XY-300DJ

- Effective welding length: ≤300 mm

- Effective shearing length: ≤300 mm

- Working mode: Hydraulic shearing, hydraulic clamping, laser welding

- Applicable thickness: 1.0–2.5 mm

- Welding speed: 500–1500 mm/min

- Travel accuracy: 0.10 mm

- Shearing pressure: 2–15 MPa

- Power supply: 380V AC

- Blade material: Cr12MoV

Laser Welding Machine

- Power: 1500 W

- Input voltage: 3-phase AC 380V ±15%

- Depth-to-width ratio: <10

- Power density: 10K–100M

- Thermal deformation: Minimal

- Feeding Device

- Motor power: 3 kW (Siemens Bede)

- Four-roll feeding system

- Two upper rolls mounted on bearing seats, lifted and pressed simultaneously via leveling cylinder and synchronous gears

- Feeding pressure adjustable via hydraulic system

- Upper structure unchanged

- Base frame welded steel structure, height increased (as per reference drawing)

- 160-Ton High-Speed Punch Press

- Welded steel plate & gantry-type box structure

- High rigidity, minimal deformation during high-speed punching

- Main transmission enclosed inside frame

- Variable frequency speed control

- Crankshaft supported by precision rolling bearings

- Combination rigid pneumatic friction clutch & brake

- Motorized die height adjustment with digital display (accuracy: 0.10 mm)

- Eight-face needle roller guide for slider

- Pneumatic balancing system

- PLC centralized control

- Imported dual safety valve

- Includes one set of punching mold (16 holes of 14×50 mm)

- Servo Feeding & Leveling Machine

- Leveling roll diameter: Φ85 mm

- Feeding rolls: 2 groups (4 rolls)

- Leveling rolls: 5 rolls

- Roll material: GCr15, heat-treated

- Servo motor power: 5.5 kW (Siemens)

- Main Roll Forming Machine

- Material thickness: 1.0–2.5 mm

- Material grade:

S235–S550,

S250GD+Z / S350GD+Z / S420GD+Z / Q235B / Q355B / Q500 / Q550 - Main motor: 55 kW VFD motor (Siemens Bede)

- Line speed: 30 m/min

- Forming stations: 17 stands

- Roller material: Cr12MoV, HRC 58–62

- Transmission: Gearbox (module 8), helical bevel gears

- Shaft diameter: Φ75 / Φ100 mm, material 40Cr

- Bearings: SKF

Encoder: Omron high-precision

7.Servo Tracking Hydraulic Flying Cut

- Cutting method: Servo tracking hydraulic cutting

- Control: PLC

- Length accuracy: ±1 mm

- Hydraulic motor: 11 kW (Siemens Bede)

- Tracking speed: ≥40 m/min

- Cutting length: 800–7000 mm (adjustable)

- Includes two cutting molds