Product description

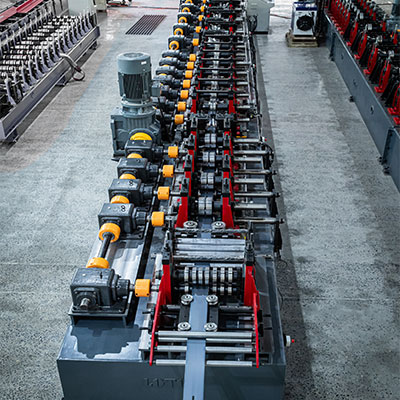

C/U Purlin Automatic Roll Forming Production Line Engineered for Precision and Strength his automatic production line is designed with robust engineering and advanced integration, offering a reliable solution for manufacturing C and U profiles across various industries.Profile Specifications:

Web: 80-200mm

Flange: 30-80mm

Raw Material Specifications:

Thickness: 2.0-4.0mm

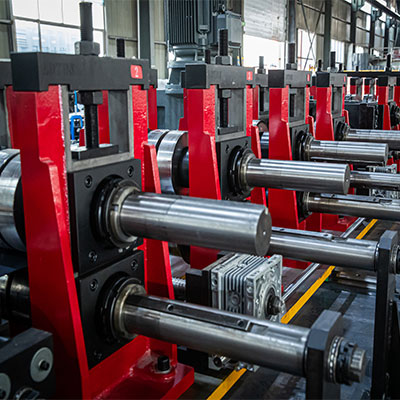

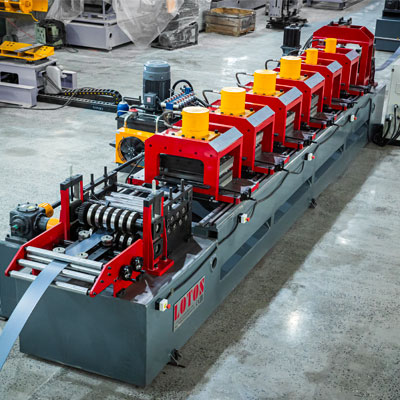

The punching system features 6 punching stations with precision dies,mounted on an isolated frame to ensure stable and vibration free operation. The machine body is built with an integrated welded frame housing and precision surface milling, providing exceptional strength and durability for heavy duty performance.For cutting, the line is equipped with a servo tracking cutting die,enabling continuous, non stop cutting to maximize efficiency. Hydraulic power is supplied by two independent pump stations: one with 22KW capacity for the punching unit and one with 11KW capacity for the cutting unit. Both are equipped with fan wind cooling systems, ensuring stable and reliable operation over extended production runs.

working flow:

Hydraulic Decoiler+Loading Cart → Looper 1# → Servo Feeding+5-roller Leveling +Hydraulic Punch Station (6 units of punch seats) →Looper 2# → Roll Forming Machine → Servo Tracking Cutting Die → Out put table

FAQ :

The servo tracking cutting system and precise sheet feeding ensure highly accurate profile lengths, minimizing scrap. This delivers significant cost savings in large scale projects

Its modular design allows seamless integration with auxiliary systems such as automatic packaging or storage units, enabling a smooth and fully connected production process.

The CZU production line is highly automated, featuring servo feeding, hydraulic punch station, roll forming, and nonstop servo cutting. However, an operator is required for tooling adjustments when changing material thickness, monitoring production, and overall safety control.