roll forming equipment

- Home

- roll forming equipment

Straightening machine for rolling mill:

roll forming equipment: One basic rule of the roll forming process is to bend the starting flat strip in a straight line, in the longitudinal direction. However, the stresses create by the forming, compound with the residual stresses in the starting material, frequently force the product to deviate from a straight line. The most frequently use terms to describe the deviations after they exit from the last pass are:

- Camber — in the horizontal direction

- Bow—in the vertical direction

- Twist — shaped in a spiral form

To correct these problems, straighteners use at the exit end of most roll-forming mills.

Straightener:

These straighteners, which correct the deviation from the straightness of the roll-form products, should not confuse with the flatteners. Flatteners use, when need, to flatten the strip ahead of the roll former.

The residual stresses in the end-products are also creating deviations from flatness, such as edge waviness, center waviness, ripples, and herringbone effects. However, straighteners cannot remove these deviations from flatness from the product.

Basic Rules of Straightening:

The straightener is forming the product with a camber or with a bow with enough pressure to create a permanent deformation in the opposite direction of the deviation.

If the deformation in the opposite direction is correct, then after spring back, the product will be straight.

If the product has a twist in one direction, then the straightener must rotate it in the opposite direction beyond the yield limit to create a permanent deformation. If the angle of the correcting rotation is right, then after spring back the product will exit straight without the twist.

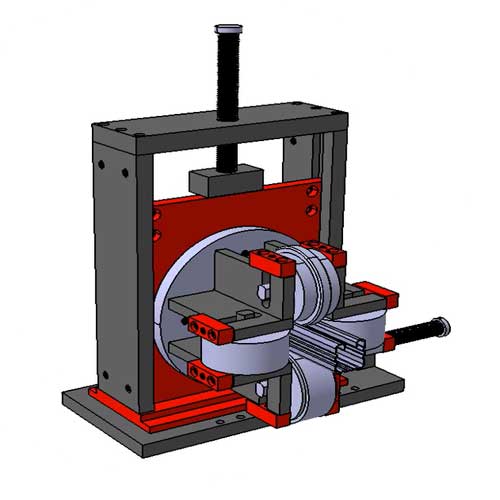

Turks head straightener:

Bending or twisting is usually correct between the last pass roll and the cutoff die. If the last pass is not supporting the product sufficiently, then the full cross section has to be supported at the entry side of the straightener. When an asymmetrical section straightens, the straightening may induce a twist. In this case, a combination of bending and twisting in the opposite directions require.

The straightening of the product does not require an all around contact between the straightener and the product surface. However, it is important that the straightener should be in contact with the product at and around the bend lines. To avoid deforming the product, the radius on the straightener should match the bending radius of the product. During straightening, the product is either pushed up or down, or either left or right.

Turk’s heads types:

Straightening Rolls:

Rolls are the simplest and longest-lasting straightening tools. They can be best apply if they can reach the bend lines. Straightening rolls also call Turk’s heads enveloping a product are also use by the tube industry.

Tool material for the straightening rolls is usually the same as to use for the forming rolls. Straightening rolls are usually not driven.

Straightening Blocks:

Blocks are the most frequently use straightening tools. The blocks envelop the section and can reach into the bend lines.

Straightening blocks usually make from two or more segments to facilitate machining adjustment, replacement of worn parts and dismantling if required.

FAQ:

Roll forming equipment is a continuous production system that shapes metal coils into precise profiles using a series of rollers. It is widely used in construction, automotive, HVAC, agriculture, and industrial manufacturing.

The process begins with feeding a metal coil into the machine. As the strip passes through multiple roller stations, it gradually forms into the desired profile. The machine may also include punching, cutting, embossing, or notching systems for complete automation.

Common materials include galvanized steel, stainless steel, aluminum, pre painted steel, copper, and high strength steel. Material thickness typically ranges from 0.3 mm to 4.0 mm depending on the application.

Industries such as construction, roofing, automotive, warehouse racking, solar energy, greenhouse systems, HVAC, and transportation rely heavily on roll forming technology.