Roll Forming Roller Design

- Home

- Roll Forming Roller Design

What is a roll forming process?

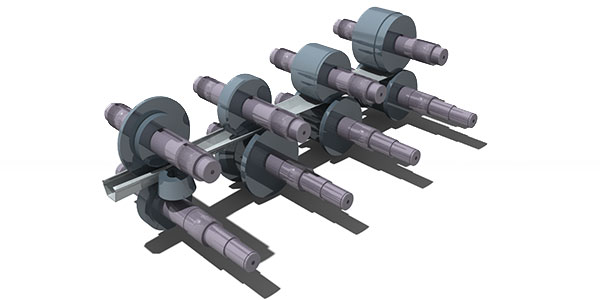

About Roll Forming machine Design, A Collection of rolls design according to the forming process (roll flower) design and adapt to form the steel sheet gradually. long production line with more than twenty stands of rolls causes the forming defects of the twisting, and the bowling, and the swinging, and the wrinkling, and the spring back of the sheet blank during the cold roll forming process.

The roll forming process involves feeding a flat strip of metal through a series of rollers that gradually bend the metal into a desired shape. The rollers are designed to apply a specific amount of force to the metal, which results in a precise bend. The metal strip is fed through the rollers continuously, resulting in a long piece of metal that has been formed into the desired shape.

How to Design for Roll Forming ?

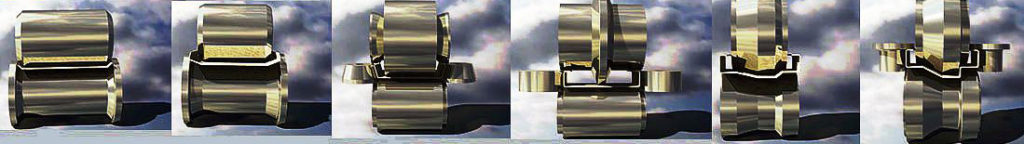

Roll forming machines that design and produce specific metals such as SS, GI, CI, PPGI, CU, and etc. The cold roll forming process is an alternative method under the condition of room temperature to form advanced high-strength steel. The forming rolls designed with relief and trap features to control the material locally and prevent the defects of folding and wrinkling.

The design of a roll forming machine is critical to its performance. A well designed machine will produce high-quality parts with minimal waste, while a poorly designed machine will result in scrap and downtime. Roll forming design involves considering factors such as the material being formed, the desired shape and dimensions, and the production volume. Experienced roll forming machine manufacturers like LOTOSFORMING have the expertise to design machines that meet the specific needs of their clients.

How did Roll Forming Machines work?

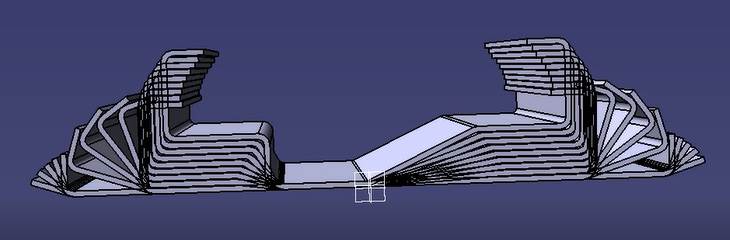

In the cold roll-forming process, a long metal strip deforms progressively through a series of rotating rolls in several stands. in order to get a required cross-section, with no decrease in the strip thickness, except in the localize bend regions. Being a progressive and continuous process, in which small amounts of forming are applied at each pass of rolls. cold roll forming employed to bend a long strip of sheet blank into a desired cross-sectional profile via roller dies.

The roll forming process is the most important metal deformation technique. One of the major metal forming processes is the passage of metal through two rollers that rotate in opposite directions.

Metals, when passing through rollers, decrease from the initial thickness to the predefined thickness.

In the rolling process, there is not only a reduction in thickness but also in the properties of materials such as hardness, strength, microstructures, and other properties.

How does roll forming work?

Roll forming machine work continues by special roll design on amount of stand. All stand drives together and will roll material with the same speed. roll forming technology came for easier and faster processing on sheet metal to precise demanded profile. each stand of tooling will make small forming on material and pass it to the next stand. as result, we will have the required profile shape.

Roll Forming machine Design, Cold roll forming is one of the complex forming processes which quality of products is highly dependent on the process parameters.

some roll forming parameters of channel section investigate on the edge longitudinal strain and bow defect of products such as bending angle increment,and strip thickness,and flange width of section, web width of the section,and friction in the roll and strip contact also speed of roll, and distance between the roll stand. It is important to consider these parameters for roll forming process design.

The “forming angle” method, which regards as reasonably dependable for assisting in the determination of the number of roll stations to form a bend, takes account of the intermittent deformation under each roll station only in a crude way.

What’s a cold roll forming ?

Cold roll forming won’t change the thickness of material during stands and rollers. Hot rolling mill is a process of changing the thickness of hot material, in cold roll forming machine we just forming room temperature material.

Cold roll-forming is a process of forming metal from the sheet, strip or coiled stock into shapes of essentially uniform cross-section by feeding the strips through successive pairs of rolls arranged in tandem. The deformation in cold roll-forming is quite complex and due to this inherent complexity of the process, the role design and other decision-making often involve a good deal of trial and error.

cold roll forming process design usually call roll design. The section profile of the demonstrated product divide into two major segments, the center rib, and the chambers, for the purpose of bending angle control.

What are the defects in the metal forming process?

1: each roll forming process line just can produce one shape profile with a range of thickness.

2: it needs feeler or wire gauges for the roller gap once raw material thickness changed.

What’s the stronger hot or cold rolled steel?

First of all we can not compare a hot rolling process with a cold rolling machine, each one has different duty for different material but generally we have much stronger cold roll forming line than a hot rolling line, meanwhile, there is so much small roll forming machine for law thickness profile.

As a result, we can tell you strong or weak base on the design of profile size and thickness.

Does cold rolling increase hardness?

No during stand rolling process the hardness of material won’t increase.

How is cold rolling done?

Its start by design then analyzing for roller, then machining and heat operation for shaft and roller, in same way frame welding and surface machining finally goes for assembly and manufacture complete cold rolling machine.

How does cold forming work?

Cold forming machine feeding by sheet metal from de-coiler then start to forming step by step, stand by stand, each tooling stand has duty for a specific amount of changing shape on the raw material.

The most noteworthy point is roll forming machine working quietly without any popping or wrinkling, the further more final profile should be without any distortion, crimp as well as misalignment. All roll forming roller parts should design by experienced professional engineering with well-known software, to get the final standard result.

What’s Difference Between Hot Rolled Steel and Cold Rolled Steel ?

actually, Hot Rolled Steel vs. Cold Rolled Steel, Hot forming is a blend of extruding and rolling using fused steel under very high temperatures. Some structural shapes really cannot produce any other method except hot forming! such as : holding up and reinforcing buildings.

cold forming means making shapes at room temperature or a few above room temperature.flat and coiled sheets are raw material typically use through roll forming machines.

FAQ:

1-What materials are used for manufacturing roll forming rollers?

Rollers are typically made from alloy steel (such as Cr12MoV, D2, or SKD11) and undergo heat treatment and hardening for durability, precision, and wear resistance.

2-How many forming stations are required for a roll forming line?

The number of stations depends on the complexity of the profile and the thickness of the material. Simple profiles may require 8–12 stations, while complex structural or closed profiles can need 20 or more.

3-Can LOTOSFORMING design rollers for existing machines?

Yes. LOTOSFORMING provides custom roller design and replacement services for any brand of roll forming machine. We can reverse-engineer existing rollers or create new designs based on your profile drawings.

4-Why is roller design important in roll forming?

The roller design directly determines the final product quality, dimensional accuracy, and production efficiency. A well-designed roller minimizes material waste, reduces stress on the machine, and extends the life of both the rollers and bearings.