A Technical Overview for Industrial Manufacturing

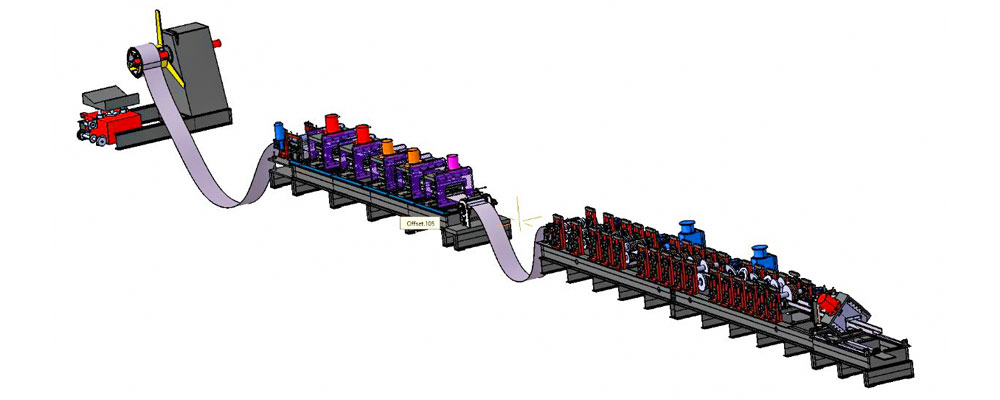

Roll forming is a continuous metal shaping process where flat steel coils are gradually bent into specific cross-sectional profiles through a series of roll stations. This method is widely used in industries that demand high precision, structural strength, and consistent quality, including construction, automotive, solar mounting systems, and industrial equipment production.

At Lotosforming, advanced solutions are designed to handle various steel types while ensuring strict tolerances and efficient production.

Steel Materials Used

Roll forming can process multiple steel materials, chosen based on strength, corrosion resistance, and end-use requirements:

Carbon Steel (Mild to High Strength)

Galvanized Steel (GI / HDG)

Pre Painted Steel (PPGI / PPGL)

Stainless Steel

High Strength Low-Alloy Steel (HSLA)

Typical thickness ranges from 0.5 mm to 8.0 mm, depending on application and machinery.

Roll Forming Process for Steel

The roll forming steel process consists of multiple technical stages:

1. Coil Feeding and Leveling

Steel coils are loaded onto a decoiler and passed through a precision leveling system to remove residual stresses and flatness deviations.

2. Progressive Roll Forming Stations

Each roll station incrementally bends the steel strip, minimizing material strain and preventing surface damage. The number of stations is determined by:

Profile complexity

Steel thickness

Yield strength of the material

3. Punching and Slotting (Optional)

Inline hydraulic or servo punching systems can be integrated for holes, slots, or embossing without interrupting production speed.

4. Cut to Length System

Flying shear or stop to cut systems ensure accurate length control with minimal burr formation.

Technical Advantages of Roll Forming Steel

Roll forming steel offers several engineering and production benefits:

High dimensional precision and repeatability

Excellent surface finish preservation

Low material waste compared to stamping

High production speed for mass manufacturing

Consistent mechanical properties along the profile length

These advantages make roll forming steel ideal for long length profiles and structural components.

Design Considerations in Steel Roll Forming

Successful roll forming of steel requires careful engineering of:

Roll tooling geometry

Forming angle progression

Springback compensation

Roll material hardness

Drive system torque capacity

Advanced CAD/CAM and simulation software are commonly used to optimize roll design and reduce trial adjustments.

Applications of Roll Formed Steel Products

Roll forming steel is extensively applied in:

Solar mounting structures

Steel framing and purlins

Cable trays and ladder systems

Automotive structural components

Warehouse racking systems

Industrial enclosures and panels

Lotosforming machines are designed to meet international standards for structural and industrial steel applications.

Automation and Control Systems

Modern roll forming steel lines incorporate:

PLC based control systems

Servo driven feeding and punching

Automated profile changeover

Real time production monitoring

These technologies enhance production efficiency, reduce downtime, and improve overall product consistency.

Roll Forming in Sheet Metal Forming

Roll forming steel is a highly efficient and technically advanced manufacturing process for producing precise, durable, and high quality steel profiles. With its ability to process various steel grades at high speed and low waste, roll forming remains a preferred solution for large scale industrial production.

FAQ:

Common materials include mild steel, galvanized steel, pre painted steel (PPGI), stainless steel, and high strength steel (HSLA), depending on the application.

Yes, Lotosforming provides fully customizable profiles, dimensions, and materials to meet specific project requirements.

Roll forming steel is a continuous cold forming process where steel coils pass through a series of precision rollers to create uniform profiles with consistent shapes and high dimensional accuracy.

Key benefits include high production speed, low material waste, excellent dimensional consistency, smooth surface finish, and the ability to produce complex profiles.