Advanced Metal Profile Manufacturing Technology

A roll forming solution is an industrial manufacturing method developed for producing continuous, uniform metal profiles with high dimensional stability. This technology is widely adopted in sectors that require long length components, consistent cross-sections, and tight tolerance control, including construction systems, energy infrastructure, storage equipment, and automotive structures. At LotosForming, engineering design focuses on structural rigidity, forming accuracy, and long term operational reliability.

Continuous Forming Process and Engineering Concept

The forming process is based on the gradual deformation of metal strip as it passes through multiple sequential forming stations. Each station applies a controlled bending force using precision machined rollers, allowing the material to reach its final geometry without sudden stress concentration. This step by step deformation significantly reduces material fatigue, surface damage, and profile distortion, ensuring high-quality output even for complex geometries.

System Architecture and Mechanical Components

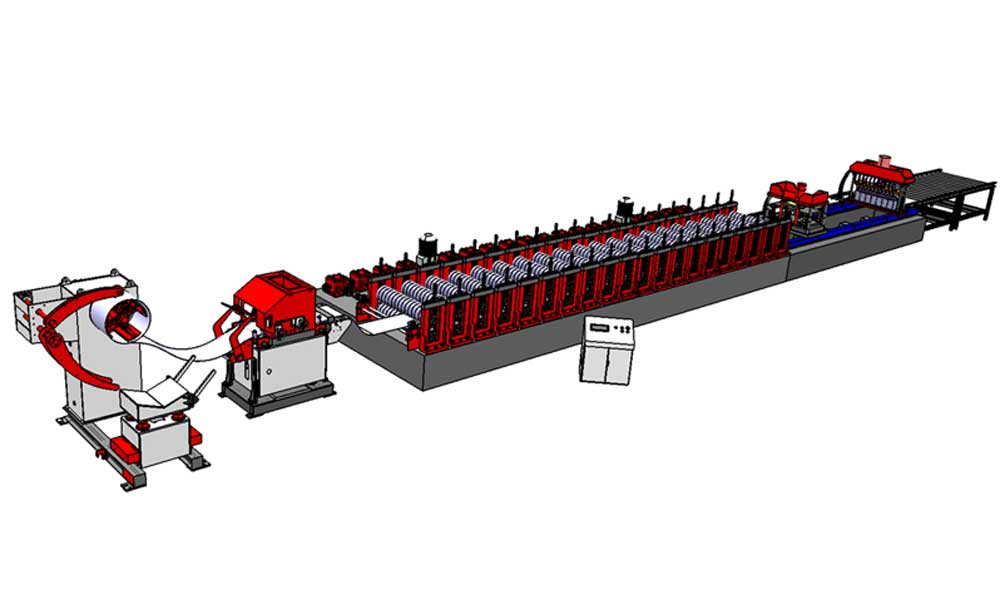

An industrial forming line is composed of several integrated modules, including coil handling, strip leveling, forming stands, inline punching or notching units, straightening sections, and automated cutting equipment. All mechanical components are mounted on heavy-duty frames and supported by high-precision bearings to maintain alignment during continuous operation. Advanced synchronization between units ensures stable production speed and consistent profile dimensions.

Material Processing Capability

This manufacturing method supports a wide range of metallic materials such as galvanized steel, stainless alloys, aluminum, and high-strength structural steel. Thickness capability and profile complexity depend on tooling design and mechanical configuration. Accurate roller profiling and shaft alignment enable excellent dimensional repeatability, minimal springback, and superior surface finish across extended production cycles.

Automation and Process Control

Modern production lines integrate PLC based control systems, servo driven feeding mechanisms, and digital length measurement technology. Operator interfaces allow real-time adjustment of forming parameters, fault monitoring, and production data management. Automation minimizes manual intervention, improves safety, and enhances overall process efficiency.

Performance and Production Benefits

Key advantages include continuous high speed operation, reduced material waste, stable product quality, and low operating cost per unit. The absence of intermittent stopping allows for smooth material flow and increased throughput, making this technology ideal for both standard profiles and project-specific designs.

Industrial Application Range

Formed profiles produced by this technology are commonly used in structural framing, solar mounting systems, cable management solutions, racking and shelving, door and window frames, and engineered support components. The ability to maintain accuracy over long production runs makes it suitable for demanding industrial environments.

LotosForming Engineering Expertise

At LotosForming, each system is developed through detailed technical analysis, tooling optimization, and application-driven design. From mechanical structure to control integration, solutions are engineered to deliver precision, durability, and production efficiency, supporting manufacturers seeking reliable and scalable metal forming equipment.

Industrial Application Range

Formed profiles produced by this technology are commonly used in structural framing, solar mounting systems, cable management solutions, racking and shelving, door and window frames, and engineered support components. The ability to maintain accuracy over long production runs makes it suitable for demanding industrial environments.

LotosForming Engineering Expertise

At LotosForming, each system is developed through detailed technical analysis, tooling optimization, and application-driven design. From mechanical structure to control integration, solutions are engineered to deliver precision, durability, and production efficiency, supporting manufacturers seeking reliable and scalable metal forming equipment.