The Role of Tooling in Custom Roll Forming

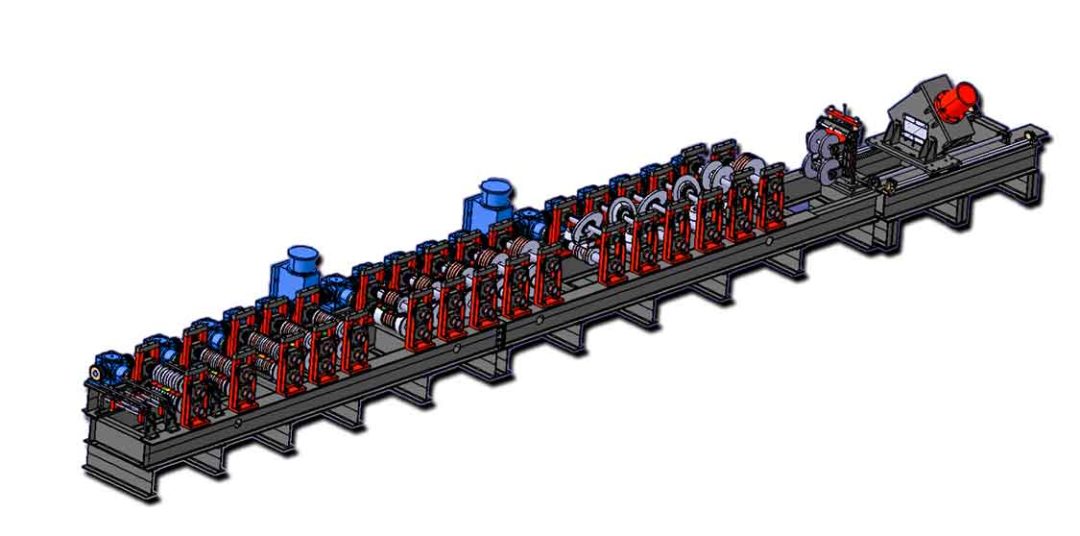

In a roll forming system, toolings play a central role in transferring mechanical force to the metal strip. Properly designed and aligned rolls reduce stress on the material, ensure smooth transitions between stations, and maintain uniform thickness throughout the profile. This balance directly impacts product quality and tool longevity.

Types of Roll Forming Toolings

There are several types of roll forming toolings, including single-roll, multi-roll, and progressive roll toolings. Each type serves a specific function depending on the material thickness, profile complexity, and production speed. Choosing the right tooling is essential for optimal performance.

Materials Used in Roll Forming Toolings

High-quality tool steel and alloy materials are commonly used in roll forming toolings. These materials provide excellent wear resistance, strength, and longevity, allowing toolings to maintain precision even under continuous production cycles.

Design Considerations for Toolings

Tooling design must consider material properties, desired profile geometry, and machine capabilities. Proper design ensures minimal springback, accurate dimensions, and smooth metal flow, which are critical for producing high-quality finished products.

Maintenance and Longevity

Regular maintenance of roll forming toolings is essential for sustained performance. Routine inspection, cleaning, and lubrication prevent premature wear, maintain dimensional accuracy, and reduce downtime in roll forming lines.

Roll Forming Metal Components

High precision toolings reduce material scrap, improve cycle times, and enable high-speed production without compromising quality. At Lotosforming, our toolings are optimized to maximize throughput while maintaining tight tolerances.

Custom Tooling Solutions

Lotosforming offers custom roll forming tooling solutions tailored to unique profile designs and production requirements. Our engineering team collaborates with clients to design toolings that meet specific operational goals and industry standards.

Investing in Quality Toolings

Investing in high quality roll forming toolings ensures long-term reliability, precision, and efficiency. Lotosforming’s advanced toolings provide the foundation for consistent production, helping manufacturers achieve superior results in metal forming operations.

FAQ:

1. What are roll forming toolings?

Roll forming toolings are precision-engineered components used in roll forming machines to shape metal sheets or strips into specific profiles. They play a crucial role in ensuring accuracy, consistency, and efficiency in metal forming operations.

2.Why are high quality toolings important in roll forming?

High quality toolings reduce material waste, prevent defects, maintain dimensional accuracy, and extend the life of the roll forming line. Investing in quality toolings ensures reliable and consistent production.

3.What types of roll forming toolings are available?

Common types include single roll, multi roll, progressive, and modular toolings. Each type is designed for specific material thickness, profile complexity, and production requirements.

4.What materials are used for roll forming toolings?

Toolings are typically made from hardened tool steels or alloy steels. These materials provide excellent wear resistance, strength, and durability, ensuring long-term performance even under high-speed production.