Roll Forming Lines and Tube Mills

Roll forming lines and tube mills are essential in modern metal fabrication, each serving distinct industrial purposes. A roll forming line gradually shapes metal sheets or strips into precise profiles through continuous rollers, ideal for applications like solar channels, strut channels, and roofing sheets. Tube mills, on the other hand, are designed to transform flat steel into round, square, or rectangular tubes using a series of rollers and welding processes. Understanding their core functions is key to choosing the right solution for production efficiency.

How Roll Forming and Tubing Works?

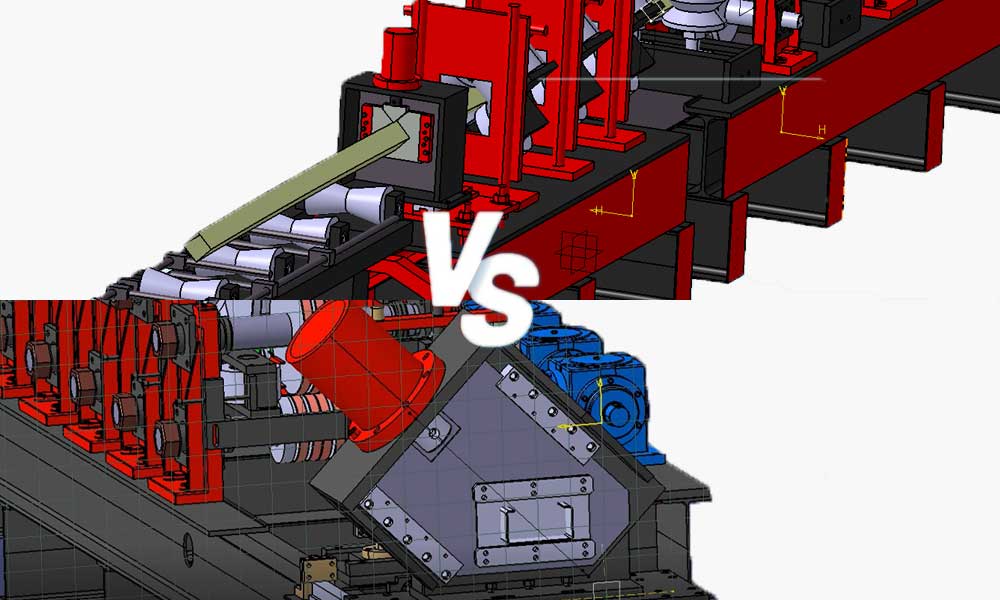

Roll forming lines excel in high speed production of uniform profiles with consistent dimensions and surface quality.They are best suited for lightweight to medium gauge materials. Tube mills specialize in creating hollow sections, providing structural strength for construction, pipelines, and automotive components. While both machines automate metal shaping, the choice between them depends on whether your production requires solid profiles or tubular products.

Material Compatibility and Flexibility

Roll forming lines handle various metals including steel, aluminum, and copper with thickness ranging from thin to medium gauge. Tube mills are optimized for steel sheets or strips, often in thicker gauges, and can produce complex welded tubes. Roll forming offers more flexibility for customized profiles, while tube mills focus on structural integrity and durability, making material selection a critical factor for manufacturers.

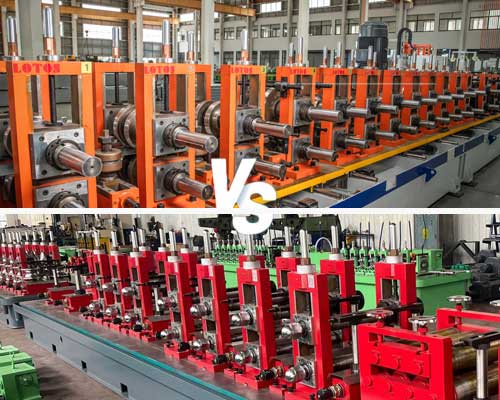

Tube Mill Line

Roll Forming Line

Automatic Roll Forming and Tube Mill Lines

Roll forming lines are designed for continuous high speed operations, significantly reducing production time for long length profiles. Tube mills require more intricate welding and shaping steps, making them slightly slower but capable of producing heavier, load bearing components. Manufacturers must weigh speed versus structural demands when choosing between these two types of machines.

Cost Considerations for Manufacturers

Investing in a roll forming line often comes with lower initial costs and maintenance compared to tube mills, especially for thin and medium gauge production. Tube mills are more expensive due to welding systems, high strength rollers, and advanced automation. However, tube mills can produce higher-value structural products, justifying the investment for industrial applications requiring strong tubular components.

Choosing the Right Manufacturer for Your Needs

Selecting a reliable manufacturer like Lotosforming ensures precision engineering, advanced automation, and long term support for both roll forming lines and tube mills. A reputable manufacturer provides tailored solutions, from design consultation to installation, ensuring that your production line maximizes efficiency, reduces waste, and meets industry standards. Choosing the right partner is as important as choosing the right type of machine.

FAQ :

What is the main difference between a roll forming line and a tube mill line?

A roll forming line shapes flat metal sheets into continuous profiles such as C, Z, U channels, while a tube mill forms flat strips into round, square, or rectangular tubes with welding.

Which industries use roll forming lines?

Roll forming lines are widely used in construction, solar mounting, strut channels, roofing, and automotive parts production.

What are tube mill lines mainly used for?

Tube mills are primarily used to produce steel pipes and hollow sections for construction, pipelines, furniture, and structural components.

Which line offers higher production speed?

Roll forming lines typically operate at higher speeds for continuous profile production, while tube mills are slightly slower due to welding and shaping steps.