What Is Sheet Metal Roll Forming?

Sheet metal roll forming is a continuous metalworking process in which long strips of sheet metal typically steel, aluminum, or stainless steel are passed through consecutive sets of precision engineered rollers to progressively bend and shape the material into a desired cross sectional profile. Unlike press braking or stamping, roll forming enables high volume production of uniform, complex profiles with minimal material waste, excellent dimensional accuracy, and consistent mechanical properties making it the preferred method for structural components, building products, and industrial applications worldwide.

Advantages of Sheet Metal Roll Forming

Sheet metal roll forming offers numerous advantages over alternative fabrication methods, including superior production speed, exceptional repeatability, reduced labor costs, and the ability to incorporate secondary operations such as punching, embossing, and cutting within a single integrated line.This process is highly efficient for long length parts and enables the use of high strength materials without compromising formability, resulting in lightweight yet robust end products ideal for construction, automotive, energy, and infrastructure sectors.

Key Applications of Roll Formed Sheet Metal

Roll formed sheet metal components are integral to a wide range of industries. Common applications include structural framing (C- and Z-purlins), roofing and wall cladding systems, door and window frames, shelving and racking systems, highway guardrails, solar panel mounting rails, electrical enclosures, and custom architectural trim. The versatility of roll forming allows manufacturers to produce both standardized and highly specialized profiles tailored to exact engineering and aesthetic requirements.

How Lotosforming Delivers High Performance Roll Forming Solutions

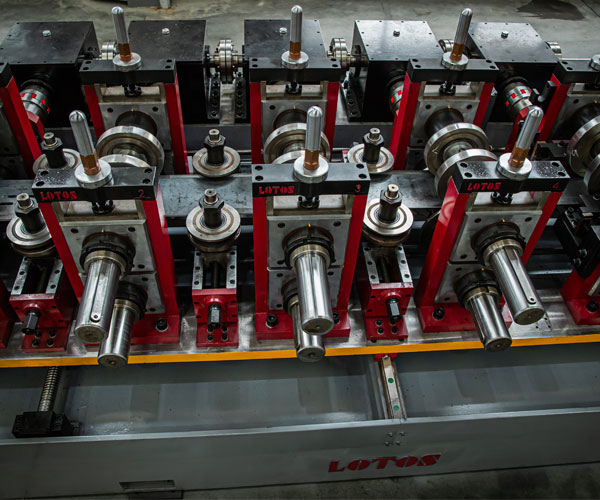

Lotosforming, a leading roll forming machinery manufacturer in China, designs and builds advanced sheet metal roll forming systems that combine German inspired engineering precision with modern automation technologies. Each machine is custom engineered using finite element analysis (FEA) and CNC machined tooling to ensure micron-level profile accuracy, long service life, and smooth material flow. With full in house R&D, machining, and assembly capabilities, Lotosforming guarantees optimal performance, durability, and ease of maintenance across all its roll forming lines.

Custom Sheet Metal Roll Forming Machines for Global Markets

Recognizing that no two production needs are identical, Lotosforming specializes in fully customized sheet metal roll forming solutions tailored to client specifications. From material type and thickness (0.3 mm to 8.0 mm) to profile geometry, line speed, and automation level, every system is configured to meet regional standards and operational demands. Lotosforming’s machines comply with CE, ISO 9001, and other international certifications, and are successfully deployed in over 40 countries across Europe, Asia, Africa, and the Americas.

Integrated Automation and Smart Manufacturing Features

Lotosforming integrates cutting edge automation into its sheet metal roll forming lines, including servo driven forming stands, PLC based control systems, human machine interfaces (HMIs), and optional IoT connectivity for real time production monitoring. These smart manufacturing features enhance operational efficiency, reduce setup times, minimize operator error, and support predictive maintenance enabling manufacturers to achieve Industry 4.0 readiness while maximizing ROI.

Quality Assurance and Rigorous Testing Protocols

Every Lotosforming roll forming machine undergoes stringent quality assurance procedures throughout the manufacturing cycle. Critical components are precision ground and heat-treated for wear resistance, while completed lines are subjected to 72+ hours of continuous dry run testing under load to validate performance, alignment, and dimensional stability. This uncompromising commitment to quality ensures that clients receive production ready systems with minimal commissioning time and long-term reliability.

Global Support and After Sales Service Commitment

Lotosforming’s partnership with clients extends far beyond equipment delivery. The company provides comprehensive after-sales support, including on-site installation supervision, operator and maintenance training, remote diagnostics, and rapid spare parts delivery through its global logistics network. With multilingual technical teams and a customer first philosophy, Lotosforming ensures seamless integration and sustained productivity for every client, regardless of location.

What Is Sheet Roll Forming ?

As a trusted leader in roll forming technology, Lotosforming combines technical expertise, manufacturing excellence, and responsive customer service to deliver superior sheet metal forming solutions. Whether you require a standard profile line or a fully automated, custom engineered system, Lotosforming offers the innovation, reliability, and global support necessary to elevate your production capabilities and competitive edge in today’s demanding markets.