Standing seam panel machine

- Home

- Standing seam panel machine

Standing Seam Panel Roll Forming Machine

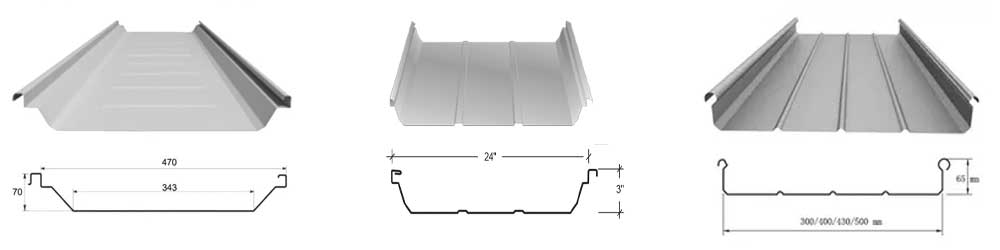

similarly, KLIP-LOK is a new production roof and wall cladding that is powerful, stable, and long length roof or wall cladding. The special fastening method provides that use on many applications such as low pitched roofs and vertical or horizontal walls.

in addition, KLIP-LOK 700 roofing sheets are available in rolled. roll-formed from certified steel means extra long lengths of Klip-Lok 700 Roof Sheeting. Klip Lok roof panel forming machine can produce continual lengths. so, KLIP-LOK roofing sheets also remove expansion joints. Kliplok Sheet Panel offers bold ribs and concealed fastening panels.in fact, LOTOS can design and produce all various types of Klip Lok machine.

Standing seam metal roof machine

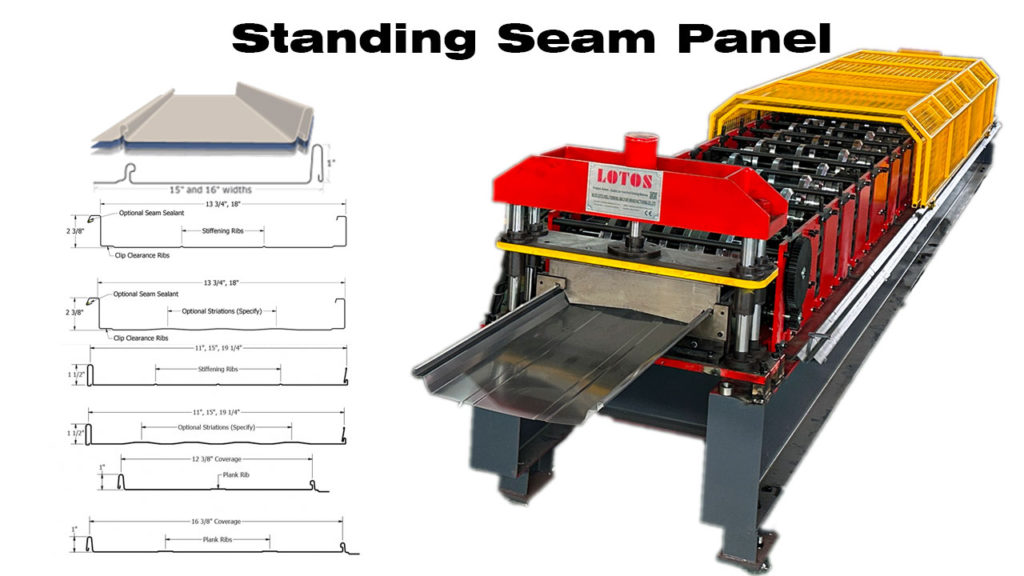

In this case, Standing seam roof panels are appropriate for use in offices, warehouses, and public facilities are hidden roof panels to solve the conventional series of roof leakage problems. A Double Standing seam roof panel is a popular choice. A Standing seam roof panel Roll Forming Machine design for continuous production of panel hidden joint. LOTOS offer an excellent quality range of Joint Hidden Roll Forming Machine to our customer.

Double lock standing seam machine

The double-lock standing seam system is a traditional flat-tray roofing system. Double-Lok panels are available in 18-inch and 24-inch widths. The Double-Lok roof panel is a mechanically field-seamed, trapezoidal leg standing seam roof system.

The use of profiling and seaming machines for the closure of longitudinal seam joints significantly reduces installation time.

Standing seam metal roof machine

In this case, Standing seam roof panels are appropriate for use in offices, warehouses, and public facilities are hidden roof panels to solve the conventional series of roof leakage problems. A Double Standing seam roof panel is a popular choice. A Standing seam roof panel Roll Forming Machine design for continuous production of panel hidden joint. LOTOS offer an excellent quality range of Joint Hidden Roll Forming Machine to our customer.

Double lock standing seam machine

The double-lock standing seam system is a traditional flat-tray roofing system. Double-Lok panels are available in 18-inch and 24-inch widths. The Double-Lok roof panel is a mechanically field-seamed, trapezoidal leg standing seam roof system.

The use of profiling and seaming machines for the closure of longitudinal seam joints significantly reduces installation time.

Snap Lok Machine

Snap lock machines can use to make ceramic tiles that use for the pavement of roofs, floors, walls, showers, and so on. We can design Snap Lock Roll forming machines according to customers’ different drawing sizes.

klip lok roofing panel machine

Klip Lok roofing is a powerful and durable long-length roof or wall cladding. Klip Lok is secured with concealed fasteners and fixed clips. This allows the sheets to be secured without being punctured. Hence, these panels are also called Boltless roof panels.

FAQ:

1-What is the production speed of a Standing Seam Panel Machine?

Typical production speed ranges from 10–25 meters per minute, depending on the machine configuration and material thickness.

2-Is installation and training included?

Yes. LotosForming offers on-site installation, commissioning, and operator training to ensure your team can run the machine efficiently and safely.

3-Does LotosForming provide after sales service?

Absolutely. We provide lifetime technical support, spare parts, and online assistance to keep your production running smoothly.