Step Beam Shelving Roll Forming Machine

- Home

- Step Beam Shelving Roll Forming Machine

Racking System Machine

A racking system is a fundamental component of warehouses, distribution centers, and storage facilities, providing efficient organization and maximization of available space. Roll forming machines play a vital role in the manufacturing process of various parts and components used in racking systems. Here’s a comprehensive description of the key parts produced by roll forming machines for racking systems:

Uprights/Vertical Frames: Uprights, also known as vertical frames or columns, are the vertical supports that form the backbone of a racking system. Roll forming machines produce uprights by shaping flat metal strips into the required profile. Typically, these profiles feature a series of punched or slotted holes for adjustable beam placement. The machines ensure precise dimensions and consistent quality to meet load-bearing requirements.

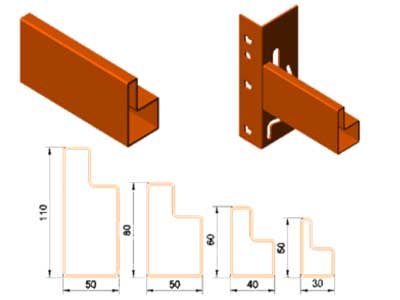

Beams/Horizontal Supports: Beams, also referred to as horizontal supports or crossbars, are horizontal members that connect to the uprights to create shelf levels within the racking system. Roll forming machines fabricate beams by forming metal strips into a box beam or channel profile. They incorporate various reinforcement features for strength and stability. Moreover, the machines enable customization of beam length, depth, and load capacity to accommodate specific storage needs.

Wire Mesh Decks/Shelves: Wire mesh decks or shelves provide a versatile and durable surface for storing goods and materials in racking systems. Roll forming machines manufacture wire mesh decks by forming and welding wire mesh panels onto support channels or frames. They ensure precise dimensions and consistent weld quality to deliver sturdy and reliable decking solutions for various applications.

Pallet Supports: Pallet supports are horizontal bars or beams installed between beams to provide additional support and prevent pallets from sagging or falling through the gaps. Roll forming machines fabricate pallet supports by shaping metal strips into channel or C-shaped profiles. They incorporate features such as flanges or lips to secure pallets in place. Moreover, the machines ensure uniform dimensions and consistent quality to enhance pallet stability and load distribution.

Overall, roll forming machines play a crucial role in the production of various parts and components for racking systems. They offer efficient and cost-effective manufacturing solutions to meet the diverse storage needs of industries worldwide. With their capability to produce precise and reliable components, these machines contribute to the construction of robust and functional racking systems that optimize space utilization and streamline warehouse operations.

Racking System Step Beam Roll Forming Machine

Pallet racking roll forming machine is widely used in producing upright frames, box beams, and step beams. Our roll forming machine could make a wide range of sizes using a cantilever type structure and automatically change by motors from one size to the other size at width and height.

in brief, the step beam shelving roll forming machine also usually called step beam roll forming machine consists of decoiler, and feeding guide, and roll forming machine, and output table, main drive, cutting, welding device, and PLC control system. The products made by Beams roll forming machines use as racks and shelves for supporting the daily commodities in supermarkets, and shops, and factory warehouses.

C Type Box Beam Roll Forming Line

The C Type Box Beam Roll Forming Line is a high-precision machine used to produce C shaped steel profiles from galvanized or cold-rolled coils. These C profiles serve as the base components for closed box beams.

Key Features:

Custom Roll Tooling for various C-profile sizes

Thickness Range: 1.5 mm to 3.0 mm

High Speed Operation: Up to 15–20 meters/minute

Inline Punching & Cutting Options

PLC Controlled Adjustment System for easy operation

This machine forms perfectly symmetrical C-channels that can later be joined to form a box shape. The profiles produced are widely used in pallet racking systems, upright columns, and horizontal beams for storage structures.

Box Beam Welding Machine

The Box Beam Welding Machine is engineered to join two C channels into a complete rectangular or square box beam using MIG, TIG, or High Frequency Welding techniques. The system is fully automated and integrated with servo motors, positioning sensors, and control software for precise welding along the full length of the beam.

Key Advantages:

Seamless Welding: Delivers clean, strong joints without the need for rework

High Production Efficiency: Suitable for mass production of structural beams

Minimal Operator Involvement: Automatic clamping, positioning, and welding

Compatible with Various Beam Sizes: Easily adjustable for different lengths and thicknesses

This machine is ideal for industries that require high strength, enclosed steel profiles capable of withstanding heavy loads, such as logistics centers, storage warehouses, cold rooms, and multi level shelving systems.

Cross Beam Roll Forming Machine

step beam Also known as crossbeams, these heavy-duty steel rails connect to the teardrop uprights to form a secure level of pallet storage. Crossbeams must always be used in pairs. Manufactured according to the standards set forth by the RMI.LOTOS produces a full range of rack roll forming machines, rack upright forming machine, step beams roll forming machine AND crossbeams ROLL FORMING MACHINE AND SO ON.

Box Beam Roll Forming Machine

- Production working flow

Manual decoiler→leveling—>Mechnical Press Machine with Punch DIE→roll forming machine→shape cutting→output table

- Machine design capacity

- Raw material thickness: 1-2 mm

- Raw material yield limit: C.S, galvanized steel

- working speed without punching: 15-20m/min

- Working area: about L12,000*W1,200mm*H1,200mm

- Machine G.W: 15,000KGS

- Machine components

This production line will be combined with a manual decoiler, leveling system, mechanical press machine with punch die, roll forming machine part, output table, hydraulic pump station and electrical control cabinet, and so on.

- Each part technical parameter

| 1. Manual decoiler | ||

| 1.1 | Loading capacity | 5T |

| 1.2 | Steel coil I.D. | φ480-φ508mm |

| 1.3 | Steel coil O.D | max φ1800mm |

| 1.4 | Cantilever width | 500mm |

| 2. Leveling Sytem | ||

| 2.1 | Roller number | 7 pcs |

| 2.2 | Motor | 4KW |

| 3. Mechanical Press Machine | ||

| 3.1 | Puncher machine | YANGLI |

| 3.2 | Press power | Mechanical 80T |

| 3.3 | Punch Die Material | Gcr12, heat treatment, Hardness 58-62° |

| 3.4 | Puncher die | 1 set |

| 4. Roll Forming Machine | ||

| 4.1 | Roller groups | 15 stations |

| 4.2 | Roller material | GCr15 with heat treatment, HRC58-62° |

| 4.3 | Roller shaft dia. | Φ80mm |

| 4.4 | Shaft material | 45# with quenching and tempering |

| 4.5 | Motor | 18.5KW |

| 4.6 | Transmission way | Gear box ( Chain available) |

| 4.7 | Machine frame body | 8mm Welded plated, Stress-Relieving |

| 4.8 | Roller supporter | nodular iron casting pillar |

| 4.9 | Roller bearing | HRB, 30213 |

| 5. Hydraulic Pump Station | ||

| 5.1 | Motor power | 4KW |

| 5.2 | Cooling way | Fan wind |

| 6. Electricity control cabinet | ||

| 6.1 | Frequency inverter | DELTA |

| 6.2 | PLC | DELTA |

| 6.3 | Screen touch screen | DELTA |

| 6.4 | Encoder | Omron |

| 6.5 | Low voltage | Schneider |

| 7. Cutting precision | ||

| 7.1 | Cutting length | ±1.0mm |

| 7.2 | Vertical Tolerance | ±1.5mm |

| 7.3 | Horizontal tolerance | ±1.5mm |

FAQ :

1-What is a Step Beam Shelving Roll Forming Machine?

A Step Beam Shelving Roll Forming Machine is an automatic production line designed to manufacture step beam profiles used in heavy-duty pallet racking and warehouse shelving systems. It forms high-strength steel beams with consistent accuracy and smooth surface finish for industrial storage applications.

2-What materials are used for step beam production?

The machine can process high-tensile galvanized steel, cold-rolled steel, or hot-rolled steel, typically with a thickness range of 1.5 mm to 3.0 mm, depending on the load capacity of the racking system.

3-What is a “step beam” in warehouse shelving?

A step beam is the horizontal load-bearing component of a racking system that supports pallets. Its “step” structure allows for easy placement of decking panels or wire meshes to hold various types of storage goods.

4-Can the machine integrate with a punching or embossing system?

Absolutely. LOTOSFORMING can include inline punching or embossing units for holes, slots, or labels according to the customer’s racking design.

5-Does LOTOSFORMING provide installation and training?

Yes. LOTOSFORMING offers on-site installation, operator training, spare parts supply, and lifetime technical support for all roll forming lines.