Roll Forming Tooling

Within the realm of continuous metal forming, roll forming stands as a preeminent process for producing consistent, complex, high strength profiles with exceptional efficiency. At the core of this sophisticated manufacturing technique lies the roll forming tooling the engineered system that progressively and plastically deforms metal coil into a desired cross section.This article provides a technical examination of roll forming tooling, its critical components, design principles, and the pivotal role it plays in production excellence.

Roll Forming Tooling System

Roll forming tooling, often referred to as a “roll tooling set” or “flower pattern,” is a sequential series of mating roll sets mounted on a roll forming machine.

Each stand in the machine contains a pair of precisely machined rolls (upper and lower) that incrementally shape the flat metal strip. The design and construction of this tooling directly determine the profile’s dimensional accuracy, surface quality, mechanical properties, and the overall line speed capability.

Core Components and Their Function

Roll Sets (Top and Bottom Rolls): The primary forming elements, typically manufactured from high grade tool steel (e.g., D2, A2) or carbide for longevity. They are hardened and meticulously ground or polished to precise geometries. Each roll pair is responsible for a specific, incremental bend in the overall forming sequence.

Shafts and Bearings: Robust shafts support the rolls under high radial and axial loads. Precision bearings are critical for minimizing deflection and maintaining accurate roll alignment, ensuring consistent forming across the entire coil length.

Side Rolls and Idler Stations: Used to support or form vertical flanges, prevent material twisting, and control springback. These auxiliary stations are essential for maintaining stability in complex profiles.

Tooling Mounting System: Includes precision machined housings, spacers, and locking mechanisms. This system ensures quick, accurate, and secure installation of roll sets, which is vital for minimizing changeover time between different profiles.

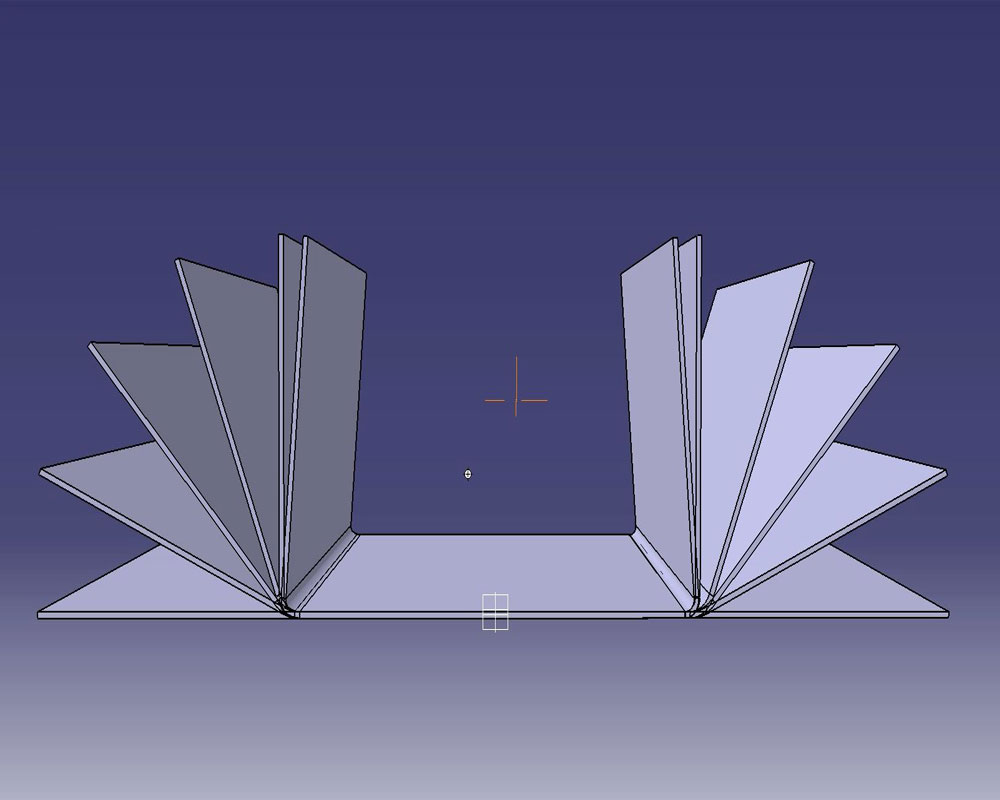

Flower Diagram

The foundational blueprint for any roll forming tool set is the flower diagram. This is not a physical component but a critical engineering schematic that maps out the cross sectional transformation of the metal from its flat state to the finished profile, stand by stand. An accurately calculated flower diagram dictates:

The Number of Forming Stands: Balancing capital cost with forming quality.

Bend Sequence and Progression: Managing strain distribution to prevent edge stretching, buckling, or oil canning.

Material Guidance: Ensuring the strip enters each subsequent roll set correctly to avoid tracking issues.

Key Technical Considerations in Tooling Design

Material Characteristics: Tooling design must account for the specific metal’s yield strength, ductility, work-hardening coefficient, and thickness. Variations in material grade or coating (e.g., galvanized, pre painted) influence roll geometry and surface treatment choices.

Springback Compensation: The elastic recovery of metal after bending must be anticipated. Rolls are intentionally over-formed to a tighter radius than the final product requires, with compensation angles calculated into the tool geometry.

Line Speed and Production Volume: High speed applications demand tooling with exceptional balance, heat treatment, and surface finishes to reduce friction, wear, and vibration.

Profile Complexity: Simple C channels require fewer stands than a closed tubular section with integrated locking seams. Complexity increases design and machining precision requirements exponentially.

Tolerancing and Finishing: Final roll dimensions are held to tolerances often within ±0.01mm. Superfinishing processes like polishing or coating (e.g., chrome plating, PVD) are applied to reduce friction and adhere to strict surface quality standards.

Roll Tooling Design & Manufacturing

Superior roll forming tooling is the linchpin for operational success. It enables:

Dimensional Consistency: Producing kilometers of profile with uniform geometry.

High Production Efficiency: Minimizing downtime through durable design and quick-change features.

Superior Surface Integrity: Protecting pre finished metals and delivering a scratch free product.

Reduced Scrap Rates: Precise material guidance and forming minimize start-up waste and in process defects.

Conclusion

Roll forming tooling represents the convergence of mechanical engineering, metallurgy, and precision machining. It is a capital investment that defines a manufacturer’s capability, flexibility, and commitment to quality. At Lotosforming, our engineering philosophy is rooted in the meticulous design and craftsmanship of our roll forming tooling systems. We understand that the integrity of the final product is inextricably linked to the precision and reliability of the tooling that creates it. By mastering these fundamental technical principles, we deliver forming solutions that ensure optimal performance, longevity, and value for every production challenge.