Variations types roll forming stands:

The roll stands mentioned here are the standard mill, with the shaft support on both sides, the cantilevered mill, where the shaft is only supported on one side, the double high mill, with two levels of rolls, and the side-by-side mill, with two sets of rolls mount on the same shaft.

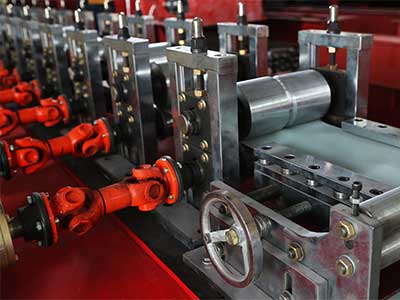

- Standard mills: The standard roll forming stand has shaft support on both sides. On the drive-side, the shaft couple to a motor that drives the rolls, on the operator-side, the stand which supports the shafts is removable in order to enable tool changing. This is the most common type of stand to roll form metals.

- Cantilevered mills: Cantilevered mills have the shaft support on only one side, the drive-side. These are simple and low-cost designs, which have been used to form simple and narrow sections. the usage of this constructive solution depends on the deflection analysis of the shaft during forming.

- Double high mills: This kind of mill is similar in construction to the standard mill but maximizes the available space by having two types of stands, one higher and one lower. This allows a factory with limited space to have two types of profiles in production in the same machine.

- Side-by-side mills: These consist of a standard mill with a longer shaft, which can accommodate two or even three sets of rolls. This reduces tool changeover time by enabling two profiles to produce in the same machine, although not at the same time; this is in a way similar to the double-high mill.