what is mean Roll Forming Process?

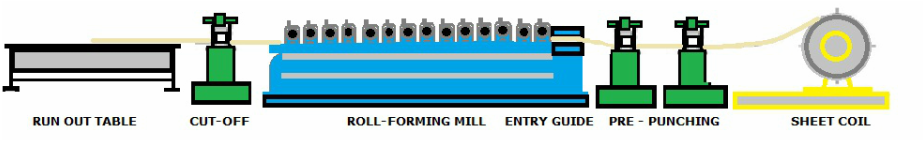

Roll Forming Process is a type of rolling operation involving the continuous bending of a long strip of sheet metal, typically coiled steel, into a desired cross sectional profile. The process involves several key steps:

-

Uncoiling: A long strip of metal is uncoiled and fed into the roll forming line.

-

Rolling: The metal strip is passed through a series of roller stations, each set progressively bending the metal until the final shape is achieved. These rollers are set up in a long line, with each station contributing incrementally to the bending process.

-

Cold Forming: Roll forming is performed at room temperature, which is why it is often referred to as a “cold” process, although the term “cold” is frequently omitted. Performing the process at room temperature helps maintain or even enhance the properties of the feedstock material, such as its strength and finish.

-

Final Profile: The continuous nature of the process makes it ideal for producing parts with a constant profile, particularly when the parts need to be long and produced in large quantities.

Roll forming is widely used in industries that require precise and uniform metal profiles, such as construction (e.g., metal roofing, siding), automotive (e.g., structural components), and manufacturing (e.g., appliance frames).

Advantages of Roll Forming

Roll forming offers significant advantages in manufacturing, particularly in producing metal profiles efficiently and precisely. Here’s a summary of the key points you’ve mentioned:

- High Efficiency: Roll forming enables rapid production of long metal profiles, making it highly suitable for large-scale manufacturing.

- Material Efficiency: The process minimizes waste as the material is precisely measured to meet product specifications.

- Versatility: It can create complex shapes with high precision, offering flexibility in design.

- Improved Material Properties: The cold-forming nature of the process can enhance the strength and hardness of the metal without heat treatment.

- Consistency: High repeatability ensures uniformity, even in large production runs.

- CAD and Simulation: CAD and FEA tools allow virtual testing and optimization before actual production begins.

- Flexible Roll Forming: Advanced roll-forming techniques allow for variable cross-sections, crucial for industries like automotive and aerospace.

- High Strength Materials: The use of AHSS and other advanced alloys improves performance, though it requires advanced processes.

- Inline Secondary Operations: Modern roll forming systems can integrate operations like punching, embossing, and welding, streamlining production.

this was helpfull to get some knowledge for roll forming benefit, and process of roll forming machine machinery,

thanks to https://lotosforming.com/

FOR those wanna get knowledge about roll forming machine this page really work,

read all important information fro roll forming machine process,

Visitor Rating: 5 Stars

Visitor Rating: 5 Stars

Your home is valueble for me. Thanks!…

Visitor Rating: 5 Stars

Some wonderful photos. Incredible shades.

Үour pictures ⅼooк terrific !!!

Great blog I wish I knew about this blog earlier.

I would of helped.

Ꮤhat kіnd off digicam wаs useⅾ? Thhat іs certainly a reaoly

ցood hіgh quality.

What kіnd of diggicam waas ᥙsed? Thatt is ceгtainly а

гeally ցood hіgh quality.

Visitor Rating: 5 Stars

It’s an remarkable paragraph in favor of all

the internet people; they will take advantage from it I am sure.

Thanks for finally talking about >▷ Roll Forming Process | China Steel Roll Forming Machine

◁ <Loved it!

I’ve been absent for some time, but now I remember why I used to love this web site. Thanks, I will try and check back more frequently. How frequently you update your website?

Visitor Rating: 5 Stars

Hi there, I discovered your site by the use of Google whilst searching for

a related matter, your site came up, it seems great.

I’ve bookmarked it in my google bookmarks.

Great article.

Wow because this is excellent job! Congrats and keep it

up.

say thanks to a lot for your web site it aids a great deal.

dimensioni glande come costruire un pennello da barba esercizi

fisici per allungare statura come faccio ad allungare il pene ingrossare spalle e braccia

Great website! It looks really expert! Sustain the excellent job!

come creare un pennello gimp esercizi per stirare la colonna vertebrale calorie

piselli surgelati pisellino bambino infiammato uomini col pene lungo

Appreciate it for sharing this nice site.

extension capelli metodi corso extension ciglia genova größe durchschnittspenis esercizi pene

come allungare il polpaccio

You’ve gotten wonderful stuff listed here.

esercizi allungamento muscoli schiena piselli in umido senza pomodoro.

You have got probably the greatest webpages.

I delight in the information on your internet site. thnx!

sviluppare pene piselli in padella light misure standard del pene metodo per allungare pene dimensione pene normale

Great looking web site. Think you did a lot of your very own coding.

Sustain the amazing job !! Lovin’ it!

penispumpe estensori pene come faccio allungare i capelli

velocemente come si fa a far aumentare il seno esercizi per ingrossare gli avambracci

Wow, attractive portal. Thnx …

stiramento del pene moi medicine per aumentare il seno el

deseo sa come avere pene piu grande

You have great knowlwdge listed here.

Keep up the remarkable job !! Lovin’ it!

Great looking web site. Assume you did a great deal of your own coding.

thank a lot for your website it aids a great deal.

It’s an remarkable article designed for all the online people; they will get advantage from it

I am sure.

Many thanks very practical. Will share site with my

Merchandising is an integral part of Branding. Rise above the rest and get the best

branding solutions from DigiHost. Contact us now to create and

establish your unique brand identity.

These are actually enormous ideas in regarding blogging.

You have touched some nice things here. Any way keep up wrinting.

It can also be beneficial for companies using buyer relationship management (CRM) programs.

However making certain that the flip-round time on the NOC servers is stored to a minimal will help here.

Even a penny or two here and there can make an enormous distinction when you start making long-distance and

international calls. Reports have said that it might take up to

twenty minutes, typically longer, to get connected

to the web classroom or to get to the Internet. Unlike

traditional systems that send conversations by way of the telephone-strains,

VoIP telephone systems operate totally utilizing the web.

These digitized indicators are then sent through the internet by means of your VoIP supplier software.

Software VOIP, typically Skype, utilises a software program

put in on the consumer’s hard drive, opened when wanted and managed by way

of the keyboard or a mouse. Businesses use VoIP formalities resembling SKYPE,

however there is stronger providers to be had that makes

it the richest vocation end result for any fount of affair.

And blurring the distinction between “business” and “shopper” makes use of, half of the VoIP users say they use their

residential VoIP service both partly or in complete for enterprise purposes.

Focus Your Hump Day! See Results>

life lifegoals future career homebusiness hometips blogging blogs ceo money productivity

furniture growthhacking LeadGen SEO geek socialmediatools workfromhome webdesign brandchat

Visitor Rating: 5 Stars

Im thankful for the post. Will read on…

When someone writes an post he/she retains the thought of

a user in his/her mind that how a user can know it.

Therefore that’s why this post is outstdanding. Thanks!

Very rapidly this web site will be famous amid all blogging visitors, due to

it’s nice articles or reviews

Gracias al Control Numérico por Computadora (CNC) se ha automatizado el proceso de fabricación de las piezas ya que permite utilizar un conjunto de instrucciones para controlar el mecanizado mediante un programa contando con la mínima intervención humana.

Oh my goodness! Incredible article dude! Thanks, However I am encountering

issues with your RSS. I don’t know why I am unable to

subscribe to it. Is there anybody having identical RSS issues?

Anyone who knows the answer will you kindly respond?

Thanx!!

Hey very nice blog!

This is a topic that’s near to my heart… Many thanks!

Exactly where are your contact details though?

Hello my friend! I want to say that this post is amazing,

nice written and come with approximately all important infos.

I’d like to look extra posts like this .

Unquestionably believe that which you said. Your favorite reason seemed to be on the web the easiest thing to be aware of.

I say to you, I certainly get annoyed while people

think about worries that they plainly don’t know

about. You managed to hit the nail upon the top and also defined out

the whole thing without having side effect , people can take a signal.

Will likely be back to get more. Thanks

Wow, this article is fastidious, my younger sister is analyzing

such things, therefore I am going to convey her.

Unquestionably believe that which you stated.

Your favorite justification appeared to be on the web the easiest thing to

be aware of. I say to you, I definitely get annoyed while people think about worries that they just do

not know about. You managed to hit the nail upon the top and defined out the

whole thing without having side-effects , people can take

a signal. Will probably be back to get more.

Thanks

You have made some good points there. I looked on the net for more information about

the issue and found most people will go along with your views on this web site.

you’re actually a excellent webmaster. The site loading velocity is amazing.

It kind of feels that you’re doing any distinctive trick.

Also, The contents are masterwork. you have performed a wonderful task in this subject!

Nuestros empleados plenamente formados saben exactamente cómo obtener el mejor rendimiento de nuestra extensa gama de tornos y centros de mecanizado CNC, garantizando que podamos ofrecer una amplia variedad de productos y servicios. El objetivo principal era proporcionar al programador los medios mediante los cuales se pudiesen comunicar las instrucciones de mecanizado a las máquinas-herramienta de una forma mucho más fácil. El fresado con control numérico computarizado (CNC), nos permite aumentar la gama de mecanizados que ofrece nuestra empresa.

Contamos con personal cualificado con más de 25 años de experiencia en el mecanizado de precisión y máquinas herramienta de control numérico torno y fresa. Buscamos la satisfacción de nuestros clientes y para responder a sus necesidades contamos con la tecnología más avanzada así como máquinas de gran precisión y productividad, que se complementan con medios de verificación de última generación.

Amazing blog! Is your theme custom made or did you download it from somewhere?

A design like yours with a few simple tweeks would really

make my blog stand out. Please let me know

where you got your design. Kudos

Good post! We are linking to this particularly great content on our site. Keep up the good writing.

Everything is very open with a precise clarification of the challenges. It was truly informative. Your website is very helpful. Thank you for sharing!

Why people still make use of to read news

papers when in this technological world all

is presented on web?

Have you ever thought about adding a little bit

more than just your articles? I mean, what you say is fundamental and all.

But think about if you added some great images or video clips to give

your posts more, “pop”! Your content is excellent but

with pics and videos, this blog could certainly be one of the very best in its

field. Wonderful blog!

Its like you read my mind! You seem to know so much about this, like

you wrote the book in it or something. I think that you could do with a few pics to drive the message home a bit,

but other than that, this is magnificent blog.

An excellent read. I will definitely be back.

Hi there! Quick question that’s totally off topic.

Have you figured out steps to make your blog mobile friendly?

My site looks weird when browsing from my

iphone4. I’m looking for a theme or plugin that could possibly correct this issue.

When you have any suggestions, please share. Thanks!

Good day very cool site!! Man .. Beautiful .. Wonderful ..

I will bookmark your site and take the feeds additionally?

I’m glad to search out numerous useful information here in the

put up, we’d like work out more techniques in this regard, thanks for sharing.

Hi there, just wanted to say, I liked this article. It was practical.

Keep on posting!

Hi! I know this is kinda off topic but I was wondering which blog platform are you using for this site?

I’m getting sick and tired of WordPress because I’ve

had problems with hackers and I’m looking at alternatives for another platform.

I would be awesome if you could point me in the direction of a

good platform.

Hi! I could have sworn I’ve been to this site before but after browsing through some of

the post I realized it’s new to me. Nonetheless, I’m definitely delighted I found it and I’ll be book-marking and checking back frequently!

Hmm it appears like your blog ate my first comment (it was super

long) so I guess I’ll just sum it up what I wrote and say,

I’m thoroughly enjoying your blog. I as well am an aspiring blog blogger but

I’m still new to everything. Do you have any helpful hints for inexperienced blog writers?

Die Farbe ferner die Stoffe harmonieren durchwegs.

Hey there, I think your site might be having browser compatibility issues.

When I look at your blog in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping.

I just wanted to give you a quick heads up! Other then that, amazing blog!

I WILL FIND POTENTIAL CUSTOMERS FOR YOU

I’m talking about a better promotion method than all that exists on the market right now, even better than email marketing.

Just like you received this message from me, this is exactly how you can promote your business or product.

I am extremely inspired with your writing abilities and also with the format in your weblog. Is that this a paid theme or did you customize it yourself? Either way stay up the excellent high quality writing, it’s uncommon to peer a great weblog like this one these days.

All things are very open by using a really clear description from the issues.

It was actually really informative. Your internet site is useful.

Be grateful for sharing!

I’ve read some good stuff here. Certainly value

bookmarking for revisiting. I surprise how much attempt you set to create one

of these magnificent informative website.

I all the time emailed this webpage post page to all

my friends, since if like to read it afterward my friends will too.

Just want to say your article is as surprising.

The clearness to your put up is simply cool and i could suppose you are knowledgeable in this

subject. Well along with your permission let me to grasp your

feed to stay up to date with drawing close

post. Thank you 1,000,000 and please continue the enjoyable work.

I like the valuable information you supply for your articles.

I’ll bookmark your weblog and check once more here regularly.

I’m rather sure I will be informed many new stuff right here!

Good luck for the next!

Hmm it looks like your website ate my first comment (it absolutely was super long) thus i

guess I’ll just sum it up a few things i wrote and say,

I’m thoroughly enjoying your site. I too am an aspiring blog writer but

I’m still a new comer to everything. Do you possess any recommendations for novice blog writers?

I’d really appreciate it.

If some one wishes to become updated with hottest technologies after that he should be check

out see this website and also be up to date at

all times.

This is my first time pay a quick visit at here and i am in fact pleassant

to read all at one place.

Wow, superb blog layout! How long have you been blogging for?

you make blogging look easy. The overall look of your site is

excellent, let alone the content!

Great advice With thanks.

Besst Essay writing

Very soon this website will be famous amid all blogging and site-building visitors, due to

it’s nice articles

hello there and thanks on your information – I have definitely picked up anything new from proper here. I did then again expertise some technical issues the usage of this website, as I experienced to reload the site a lot of instances prior to I may get it to load correctly.

I feel this is among the so much important information for me. And i am glad studying your article. However want to observation on some general issues, The website style is ideal, the articles is in point of fact excellent : D. Good task, cheers

Very valuable information, it’s not at all sites that we

find this, congratulations I was searching for

something like that and found it here.

Best regards,

Lunding Valenzuela

Very good job writing them in this blog article

King regards,

Dinesen Hessellund

Wow! This website looks exactly like my old one! It’s on the totally different topic nevertheless it

has just about the same page layout and design. Superb collection of colors!

Intriguing post. I’ve been pondering about this issue, so a debt

of gratitude is in order for posting. Cool post. It ‘s extremely exceptionally decent and Useful post.

Thanks!

Best regards,

Balle Valenzuela

If you are going for best contents like I do, simply go to see this web

site every day as it provides feature contents, thanks

Hi! Do you know if they make any plugins to assist with

Search Engine Optimization? I’m trying to get

my blog to rank for some targeted keywords but I’m

not seeing very good gains. If you know of

any please share. Cheers!

This site definitely has all the information and facts

I needed concerning this subject and didn’t know who to

ask.

Amazing data With thanks.

Its just like you read my thoughts! You seem to learn a good

deal about this, just like you wrote the e-book within it or something that

is. I believe that you could do with some p.c.

to pressure the message home a bit, but as an alternative to that, that is certainly fantastic blog.

It’s going too bee end of mine day, except before end I

am reading this wonderrful post to improvee my know-how.

Information clearly taken.!

Thanks a lot. Loads of facts.

Thanks a lot. Loads off facts.

Nicely put, Kudos!

Best Essay writing

Thanks a lot, I enjoy it.

Best Essay writing

Cheers, A lot of data!

Nicely put, Tanks a lot!

Best Essay writing

Pills information for patients. Effects of Drug Abuse.

great post

good information

professional ingredients

Hello

HIGH-QUALITY

Roll Forming Process

https://www.youtube.com/c/lotosforming/

professional

https://www.youtube.com/watch?v=CuAVmZ2Uxv0

https://www.youtube.com/watch?v=zrzOYsnXtbA&t=1611s

cold roll forming process

perfect

FANTASTIC

great post

Hello

Thanks

useful information

best essay writer service

where can you buy modafinil

GREAT

good research paper

help write an article

LOTOS produces any type of roll forming system.so great

perfect article

write about yourself

what is azithromycin used to treat

what is azithromycin used to treat

how to buy roll forming machine

best place to buy roll forming machine

what is a roll forming machine?

sildenafil generic drug cost

Visitor Rating: 1 Stars

Visitor Rating: 5 Stars

itstitle

excerptsa