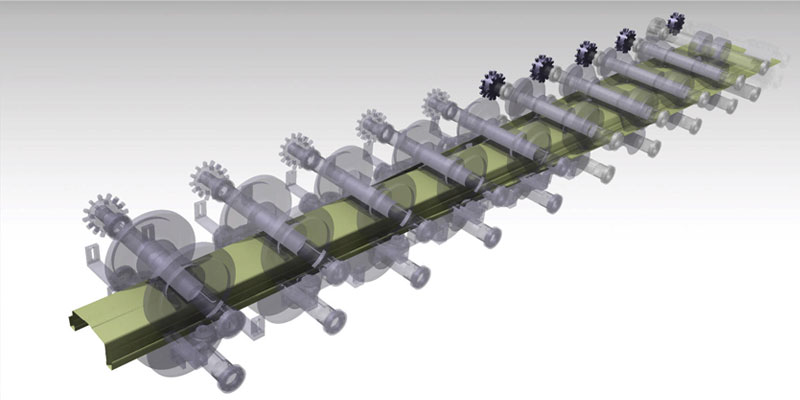

The Importance of Precision in Roll Forming Tooling

Roll forming tooling plays a pivotal role in the efficiency, accuracy, and quality of metal forming processes. At Lotosforming, we understand that the success of any roll forming operation hinges on the design and calibration of tooling components. Precision engineered tooling ensures consistent cross sectional profiles, minimizes material waste, and reduces production downtime. By investing in high tolerance roll forming tooling, manufacturers can achieve superior surface finishes and dimensional accuracy, ultimately enhancing product reliability and customer satisfaction.

Custom Roll Forming Tooling Solutions for Diverse Applications

Every manufacturing requirement is unique, and off the shelf tooling rarely meets the demands of specialized applications. Lotosforming specializes in custom roll forming tooling tailored to the exact specifications of our clients’ projects. Whether for automotive, construction, or HVAC industries, our engineering team collaborates closely with clients to develop tooling that accommodates complex geometries, varied material thicknesses, and high volume production needs. This bespoke approach ensures optimal performance and longevity of the roll forming system.

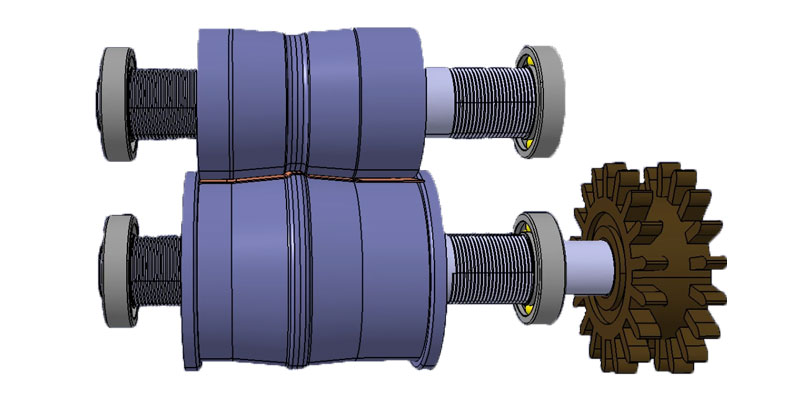

Advanced Materials and Coatings in Roll Forming Tooling

The durability and performance of roll forming tooling are significantly influenced by the choice of materials and surface treatments. At Lotosforming, we utilize advanced tool steels and apply specialized coatings such as TiN (titanium nitride) and DLC (diamond like carbon) to enhance wear resistance and reduce friction. These innovations not only extend the tooling’s service life but also maintain consistent product quality over extended production runs, reducing the frequency of maintenance and replacements.

Role of CAD/CAM Technology in Modern Roll Forming Tooling Design

The integration of CAD/CAM technology has revolutionized the design and manufacturing of roll forming tooling. Lotosforming leverages state of the art software to simulate forming processes, analyze stress distribution, and optimize tool geometry before physical production begins. This digital first approach minimizes prototyping costs, accelerates time to market, and ensures that every set of tooling performs flawlessly under real world operating conditions.

Maintenance Best Practices for Roll Forming Tooling Longevity

Proper maintenance is essential to preserve the integrity and performance of roll forming tooling. At Lotosforming, we recommend regular inspection, cleaning, and lubrication schedules to prevent premature wear and alignment issues. Our team also provides clients with comprehensive documentation and training on handling, storage, and troubleshooting best practices. By adhering to these protocols, manufacturers can maximize tooling lifespan and maintain consistent output quality across production cycles.

Ensures Superior Roll Forming Results

Choosing the right partner for roll forming tooling is critical to achieving long term operational success. Lotosforming combines decades of industry expertise with a commitment to innovation, precision, and customer collaboration. From initial concept through final delivery, our end to end solutions are designed to meet the evolving needs of modern manufacturing. By partnering with us, clients gain access to world class engineering support, rapid turnaround times, and tooling solutions that drive efficiency, quality, and competitiveness in the global marketplace.

FAQ :

Standard tooling often cannot accommodate unique profiles, material types, or production volumes.Custom roll forming tooling designed and manufactured by Lotosforming is tailored to your exact specifications, ensuring optimal forming efficiency, reduced material waste, and minimized downtime. Whether you’re working with high strength steel, aluminum, or specialty alloys, custom tooling guarantees consistent output and long-term reliability.

Lead times vary depending on complexity, but Lotosforming typically delivers custom roll forming tooling within 4 to 8 weeks from final design approval. Our integrated CAD/CAM and CNC machining capabilities enable rapid prototyping, precise manufacturing, and thorough quality validation ensuring your tooling is production-ready without unnecessary delays.

Tooling design directly impacts dimensional accuracy, edge quality, twist, bow, and overall profile consistency. Poorly designed or misaligned tooling can cause material deformation, surface scratches, or inconsistent tolerances. Lotosforming employs finite element analysis (FEA) and forming simulation to optimize bend sequences, neutral axis control, and strip stability ensuring your final product meets stringent quality standards.

Regular maintenance is key: clean rollers after each run, inspect for wear or misalignment, apply appropriate lubricants, and store tooling in a dry, temperature controlled environment. Lotosforming also provides maintenance guidelines and training to help operators maximize tooling performance and longevity.