welded pipe and square forming machine

Here is a proposal for welded pipe or square profile also called tube mill production line. Tube mill production line as you can see from name included several different parts and machine to become a complete line.

tube mill production line

1-Decoiler: Tube mill line will start from Decoiler, to open steel coil to a sheet for forming and processing. uncoiler or Decoiler has several different types: HYDRAULIC or MANUAL or MECHANICAL or SINGLE SIDE or DOUBLE SIDE, AND SO ON SO MOSTLY LOTOSFORMING uses double side hydraulic uncoiler for tube mill production line.

double head hydraulic uncoiler

Tube manufacturing processes for seamless and welded tubes

2- shearing and butt welding machine: after decoiling steel coil mostly line has shearing and butt welding machine. its simple and small machine for shears the end of steel strips and welded both sides of steel strips to make tube mill line continuously. Also, some line does shearing and welding without a machine, with simple welding tools.

shearing and butt welding machine

3- steel raw material accumulator: its mostly use for storage steel strips before forming because forming speed and working is not same all times and raw material should have stable feeding for continues welding and processing. Tube mill line accumulating from LOTOS has 2 different styles.

horizontal accumulator

A: horizontal round material accumulating that has 2 AC motor, one for feeding steel strips from decoiler and secondary for driving accumulating, estimate OD of this part of tube mill line is 5 meter.

vertical accumulator

B: Vertical material accumulator it also has 2 AC motor, one for feeding raw material from decoiler to accumulator and another one for driving material accumulator. Selecting accumulator is based on customer producing area and budget.

Stainless Steel Pipe Making Machine

4- forming stations: this part of tube mill line is similar with Roll forming machines, but except horizontal shaft and roller it also forms material by vertical roller, to make tube shape and ready for welding. LOTOSFORMING mostly use 7-10 stations drive by heavy gears for forming.

forming stations

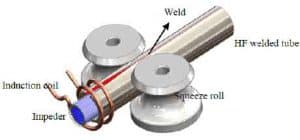

5- pre-welding Guide and squeeze roller: this station is really important to make straight steel pipe seam for welding. this part makes sure pipe seem to inter to welding position flatly and squeeze roller make pressure both side of the tube to ensure the seam gap.

guide and scraper

6- high-frequency welding: as you know this kind of welding is without electrode by high-frequency welding HF WELDER has several types by power LOTOS FORMING USE 200-400 ampere. this part of tube mill line includes serval different parts, such as Overall control table, Speed adjustor, Rectifier cabinet, Inverter output cabinet, Water-water cooling device (air-water cooling device) and so on plz refer to figure for all parts.

high-frequency welding accessories

squeeze roll and welding induction coil

7- scraper tools: to scrap welded seam, we can also scrap inside and outside of the tube to have a smooth surface for welded tubes.

8: Zinc spraying machine: this is optional for customers, but for making galvanized tube mill by galvanized steel we add zinc spraying machine after HF welding to coat the welding seam by Zinc spray. This machine uses zinc wire diameter 1.5-3 mm to MELT and spray zinc on the welded seam.

zinc spraying machine

Tube making process

10- Sizing stations: formed pipe after welding come to sizing stations to control size accuracy. Also for making the square profile in this station, we form welded pipe to various square profile. all horizontal and vertical roll stand drives by Spiral bevel gear, by a separate 40Cr shaft.

sizing stations

11- final straightening: these 2 stations straight pipe or profile by Turk’s head type, and 360°rotary after sizing to reach the required straightness before cutting.

rolling mill

12: CNC controlled cold cutting saw: by tube mill forming speed near 70 meters per minute we definitely need flying the cutting saw to reach back point on this speed. LOTOSFORMING has 2 types of the cutting saw: one is normal another is a cold cutting unit.

Cold cutting unit advantages it makes a finished profile without burr, to has the best accuracy and less cutting noise some industry required cold cutting saw.

cold cutting unit for tube mill production line

13: run out table and packing system: finally after all processing to make steel tube or steel square profile we go to pack products for storage and shipping. LOTOS FORMING has several different packing systems for tube mills line, it’s up to customer requirement. here you can see the picture of automatic run out table and packing unit for square profiles.

automatic packing system for tube mill lines

that’s great post

Visitor Rating: 5 Stars

Visitor Rating: 5 Stars

Incredibly individual friendly website. Immense information offered on couple of gos to.

Hello There. I discovered your blog using msn. This is a really well written article.

I will make sure to bookmark it and return to learn extra of

your useful information. Thank you for the post.

I will certainly return.

I love looking at your internet site. Thank you!

deseo banyuls sur mer ricostruzione unghie tip senza gel massaggi per

ingrandire il pene come aumentare le dimensioni del glande misure dei peni

Merely want to stress I am just thankful I stumbled in your website!

Visitor Rating: 5 Stars

Hey very nice blog!

great

perfect

perfect

Rolling mill

Rolling mill for tube

https://www.youtube.com/watch?v=93AnkwrumQM&t=126s

great post

Rolling mill for tube

you are perfect

GREAT POST

great