What is Roll Forming?

- Home

- What is Roll Forming?

How Does Roll Forming Work?

Roll forming is a flexible process, where both the basic rules and the exceptions can employ. It proved several times that even apparently impossible roll forming tasks can do. On other hand, it has also shown that plans to roll form simple shapes can create heinous results if the basic rules of roll forming are not followed.Roll Forming Basic Requirements

Satisfying Customers:

Roll formed products sale to customers in a very competitive market. Customers are always looking for manufacturers who can frequently meet their basic requirements.

They are expecting to receive:

- The right quality

- right quantity of products

- At the right time

- For the right price

Companies not able to supply the right quality and quantity, at the Specified time for the right price will lose their customers. To successfully meet the demands and outperform the competitors, manufacturing plants must have:

- Good product drawings to be manufactured

- Sufficient run quantities

- correct material to be formed

- suitable equipment

- Good tooling

- A knowledgeable, motivated workforce

What is a Roll Forming machine?

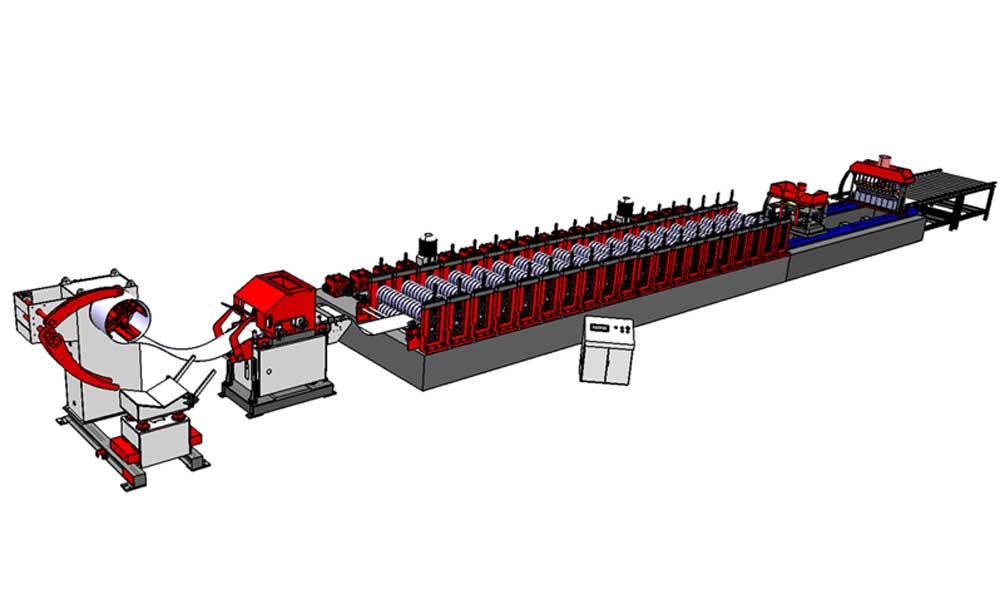

Raw material decoiler, tooling machine with the amount of alignment stand and roller, cutting and the punching unit, that together we call roll forming machine. Roll forming is a continuous bending process during which the thin sheet of metal successively passes through a set of rolls that incrementally bend it until the desire cross-section obtain.

Installation of Roll Forming Lines

Installing a roll forming line involves several key steps:

Site Preparation

Ensure the production floor is level and has sufficient space for machine layout.Machine Positioning

Uncoilers, roll forming stands, cutting units, and control panels must be aligned correctly.Electrical & Pneumatic Connection

Proper connection of motors, PLCs, hydraulics, and safety systems is essential.Trial Run & Calibration

Test with material to calibrate rollers, adjust straightening, and verify profile accuracy.

FAQ:

The metal strip passes through consecutive sets of rollers, each performing incremental bends until the final shape is achieved, ensuring precision and consistency.

Roll forming typically works with metals such as steel, aluminum, copper, and other alloys, depending on the application and thickness requirements.

Roll forming provides high production efficiency, uniform quality, minimal material waste, and the ability to create complex profiles that are difficult with other methods.

Roll forming is widely used in industries such as construction, automotive, furniture, and appliance manufacturing for products like metal door frames, roofing sheets, and cable trays.

.